Airplane cockpit windshield structure with sun shading function

A cockpit and windshield technology, which is applied in the field of aircraft cockpit windshield structure design, can solve the problems of increased daily workload, loose and sagging sunshade devices, and increased aircraft weight, so as to improve economic performance, facilitate operation, and reduce weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

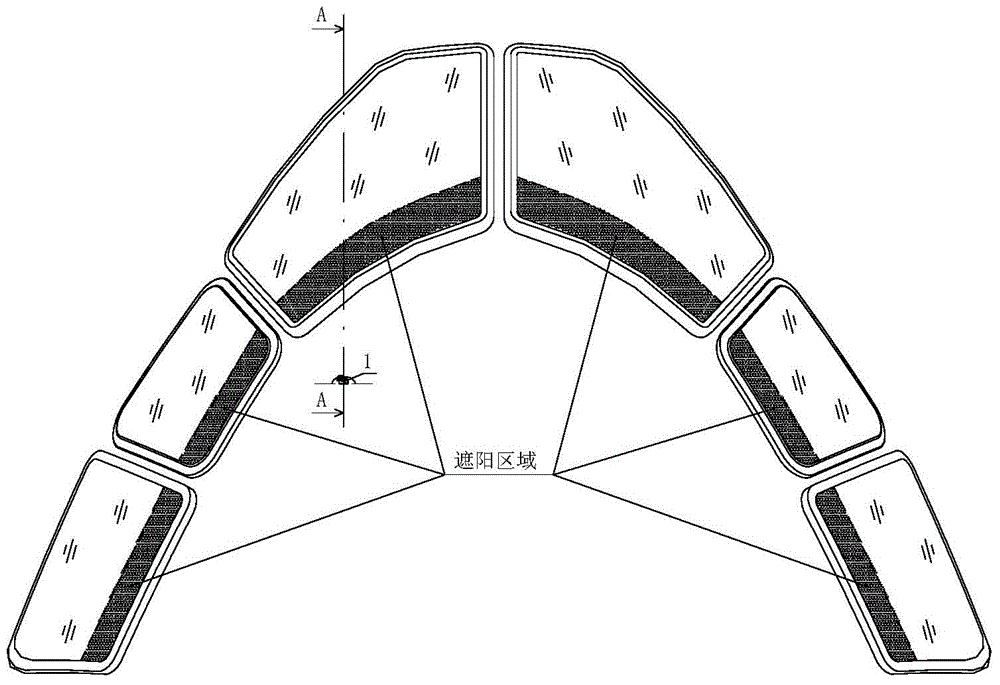

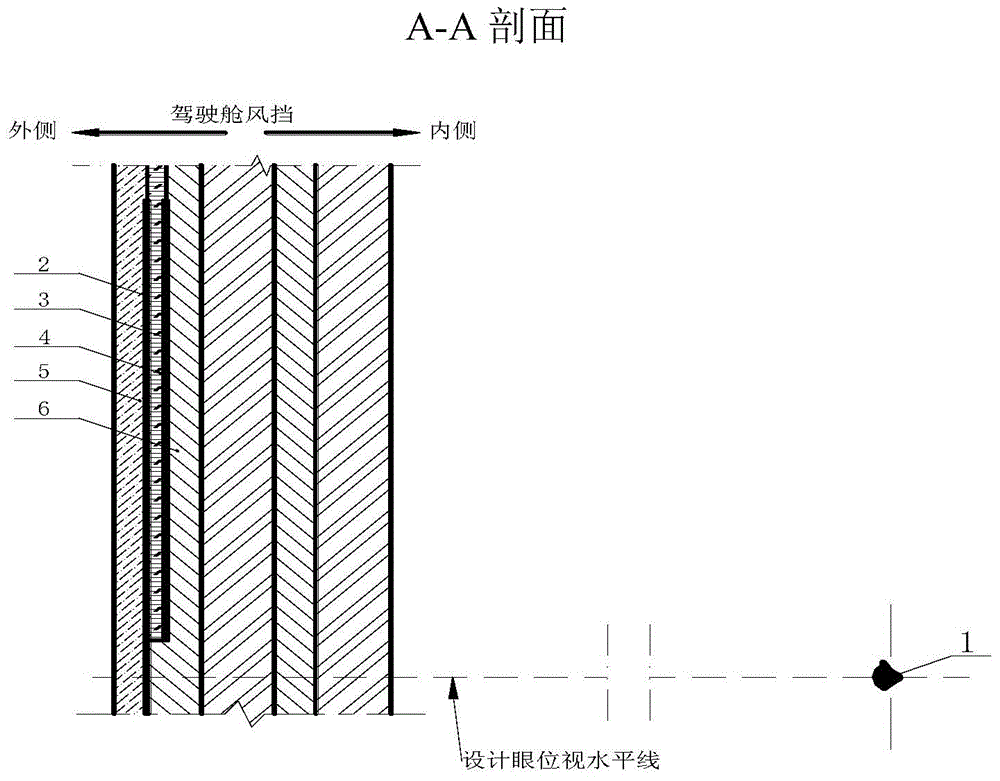

[0015] The present invention will be described in further detail below. see figure 1 , figure 2 , an aircraft cockpit windshield structure with sun-shading ability, is characterized in that it is based on the sandwich structure windshield of various transparent materials of the traditional aircraft cockpit, and is determined according to the design eye position 1 of the aircraft cockpit. The windshield area above the horizontal line or the smaller windshield area is a sunshade area. In this area, a transparent ITO conductive heating film 3 is coated on the interlayer surface of the transparent ITO conductive heating film 2 adjacent to the outer layer of the windshield in this area, and two layers of ITO conductive heating film are coated. Between 2 and 3, a transparent nano-electrochromic sunshade film 4 is set, and a conductive bus bar 7 is set on the upper and lower edges of the outer ITO conductive heating film 2, and a similar conductive bus bar is set on the upper edge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com