Circuit board automatic loading device

An automatic loading and circuit board technology, which is applied in the directions of transportation and packaging, stacking receiving devices, object supply, etc., can solve problems such as poor storage order of circuit boards, easy slipping of circuit boards, and uneven contact between circuit boards and pushing mechanisms , to achieve the effect of improving storage uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

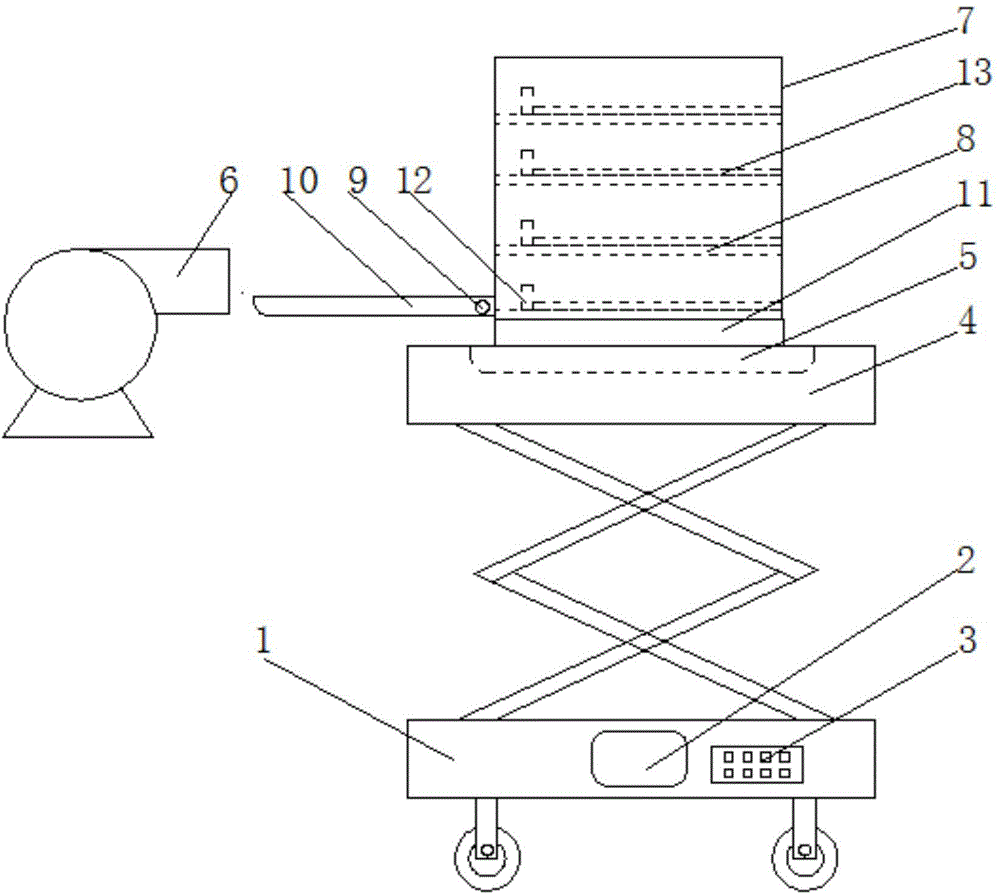

[0019] Such as figure 1 As shown, this embodiment includes a lift 1, a display screen 2, a button area 3, an operating table 4, an electromagnet 5, a suction fan 6, a storage board box 7, a partition 8, a rotating shaft 9, a movable door 10 and an iron adsorption plate 11. The front part of the elevator 1 is provided with a display screen 2 and a button area 3. The elevator 1 is a mobile elevator. The upper part of the elevator 1 is fixed with an operation table 4. The operation table 4 is equipped with an electromagnet 5. The upper right part of the operation table 4 is placed with a The storage board box 7, the suction fan 6 corresponding to the storage board box 7 is placed on the left side of the operation table 4, the inside of the storage board box 7 is fixed with a partition 8 horizontally, and the distance between the height of the air outlet of the suction fan 6 and the partition 8 Matching, the upper left part of the partition 8 is fixed with a soft stopper 12, the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com