Temperature control safety explosion-proof lamp

An explosion-proof lamp and safety technology, which is applied to the safety device of the lighting device, the lighting device, the cooling/heating device of the lighting device, etc., can solve the problems of injuring the surrounding staff, heating the surface of the electrical equipment, hidden dangers of the explosion-proof lamp, etc. Achieve the effect of ingenious structure, simplified installation procedure, and solved production cost and production difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

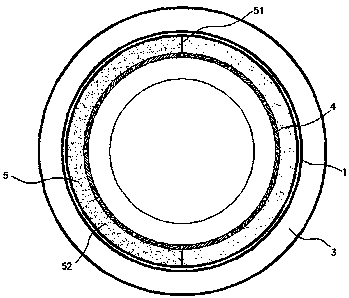

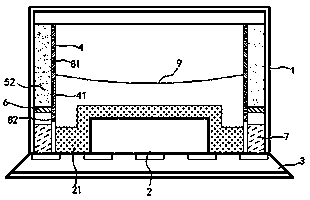

[0014] exist figure 1 , figure 2 In the shown embodiment, the temperature control safety explosion-proof lamp includes a housing 1, a lamp sheet 2 and a lampshade 3, and the lampshade 3 seals and fixes the lamp sheet 2 on the housing 1; The back of the sheet 2 is attached with a heat dissipation block 21 with good heat conduction; a cylindrical partition 4 is installed in the housing 1, and the upper and lower ring edges of the partition 4 are respectively airtightly connected to the top plate of the housing 1 and the back of the light sheet 2; the partition 4 is in close contact with the heat dissipation block 21; it is installed symmetrically in the airtight annular cavity 5 surrounded by the partition 4, the housing 1 and the light sheet 2 There are two sub-chamber plates 51, which divide the annular cavity 5 into two independent semi-annular liquid storage chambers 52; Annular piston sheet 6; coolant is filled above the piston sheet 6, and air and expansion glue 7 are f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com