High-voltage direct current power transmission grounding electrode with cooling system and temperature control system

A high-voltage direct current transmission and direct current transmission technology, applied in the direction of direct current network circuit devices, electrical components, circuit devices, etc., can solve problems such as inability to handle, inconvenience of manual operation and maintenance, and adverse effects on the stability of the direct current transmission system, so as to improve stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

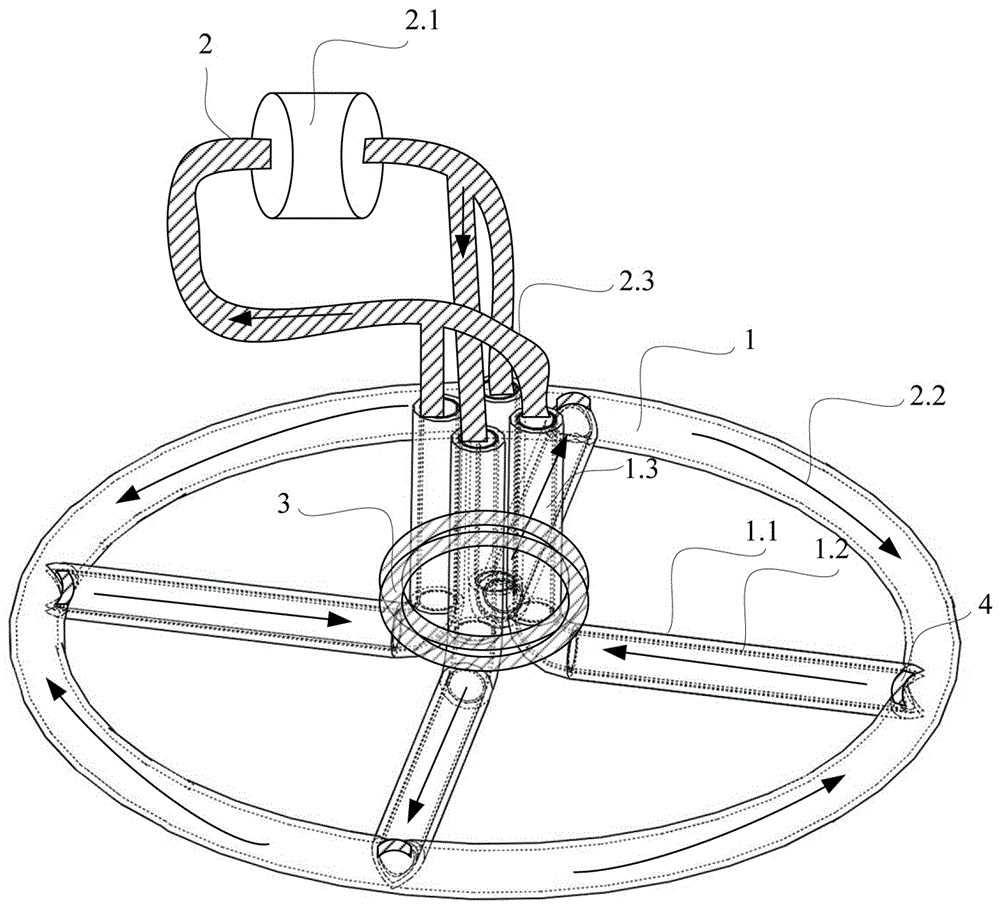

[0031] according to figure 1 As shown, the cavity conductor 1.1 with an insulating layer 1.2 is used as the DC transmission grounding electrode 1, the current transformer 3 is installed on the down conductor 1.3 of the DC transmission grounding electrode 1, and the temperature sensor 4 is installed on the DC transmission grounding electrode 1 At the welding place, the water circulation system 2 is formed by using the soft water pipe 2.3 to construct the direct current transmission grounding electrode 1 and the water pump 2.1.

[0032] Measure the grounding current of the DC grounding electrode through the current transformer 3, if it is judged that the average temperature of the DC grounding electrode is greater than 50°C; increase the output power of the water pump 21, increase the water flow rate of the water circulation system 2, and gradually make the DC grounding electrode The temperature drops below 50°C.

specific Embodiment approach 2

[0034] according to figure 1 As shown, the hollow conductor 1.1 with an insulating layer 1.2 is used as the DC transmission grounding electrode 1, the current transformer 3 is installed on the down conductor 1.3 of the DC transmission grounding electrode 1, and the temperature sensor 4 is installed on the DC transmission grounding electrode 1 At the welding place, the water circulation system 2 is formed by using the soft water pipe 2.3 to construct the direct current transmission grounding electrode 1 and the water pump 2.1.

[0035] Measure the grounding current of the DC grounding electrode through the current transformer 3, if it is judged that the average temperature of the DC grounding electrode is less than 45°C; reduce the output power of the water pump 2.1, reduce the water flow speed of the water circulation system 2, and gradually make the DC grounding electrode The temperature rose back above 45°C.

specific Embodiment approach 3

[0037] according to figure 1 As shown, the hollow conductor 1.1 with an insulating layer 1.2 is used as the DC transmission grounding electrode 1, the current transformer 3 is installed on the down conductor 1.3 of the DC transmission grounding electrode 1, and the temperature sensor 4 is installed on the DC transmission grounding electrode 1 At the welding place, the water circulation system 2 is formed by using the soft water pipe 2.3 to construct the direct current transmission grounding electrode 1 and the water pump 2.1. Use the temperature sensor 4 to measure the temperature of the welding part of the DC transmission grounding electrode 1; when the temperature of a certain welding part is detected to be greater than 90 °C and the duration is greater than or equal to 1 hour, it is judged that there is a local temperature rise fault in the DC grounding electrode, and the fault is reported as Basis for maintenance plan.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com