Superheater device adapting to operation on variable working conditions of boiler and control method thereof

A control method and superheater technology, applied in the field of boilers, can solve the problem of low flow rate and achieve good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

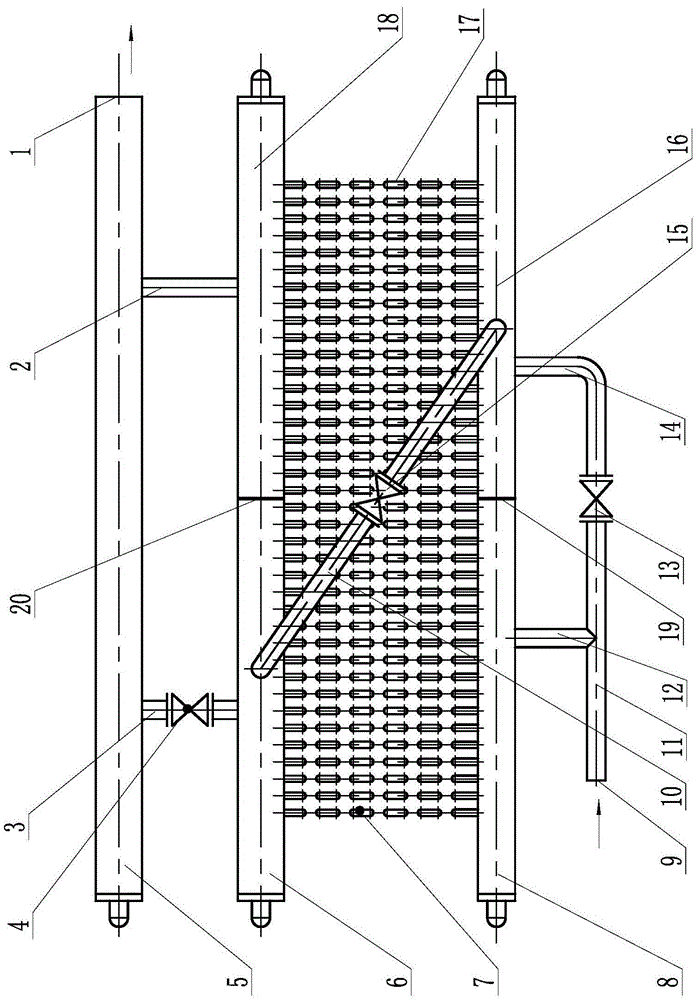

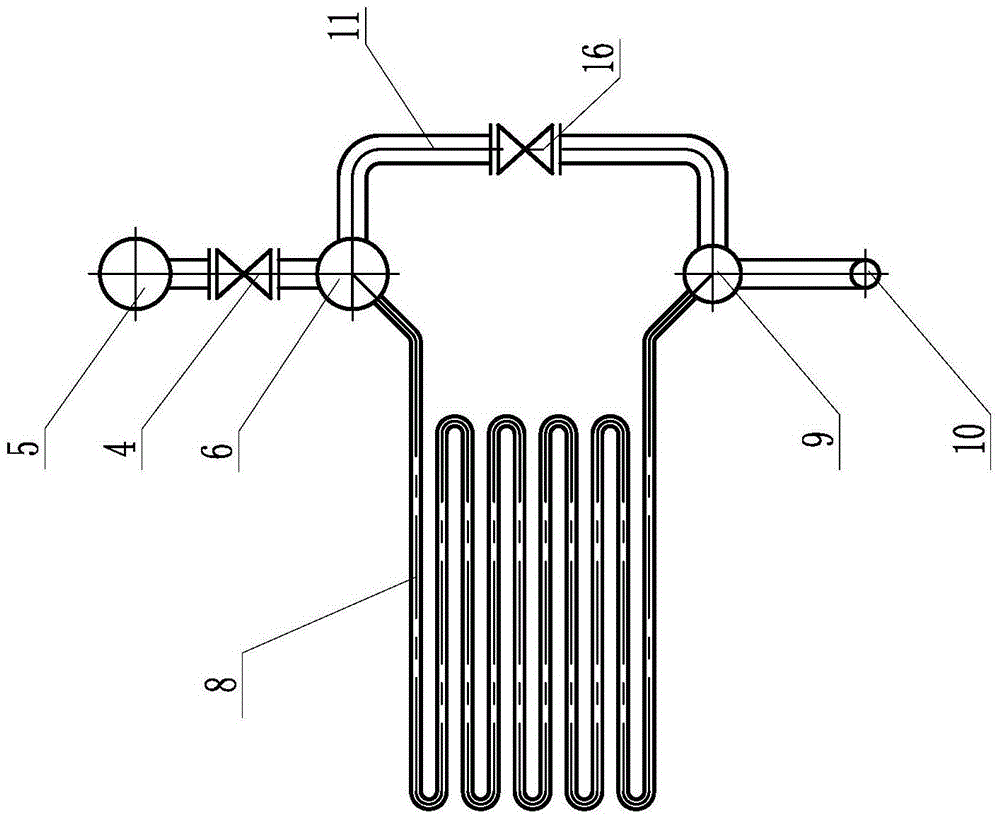

[0015] refer to figure 1 , a superheater device of the present invention suitable for boiler variable operating conditions, including a steam inlet pipe 11, a first steam inlet pipeline 12, a second steam inlet pipeline 14, a first inlet header 8, a second inlet header Box 16, first row pipe 7, second row pipe 17, return line 10, first outlet header 6, second outlet header 18, first parallel steam pipeline 3, second steam parallel pipeline 2, distribution header 5, the first shut-off valve 13, the second shut-off valve 15 and the third shut-off valve 4, the two ends of the first steam inlet pipeline 12 are respectively connected with the steam inlet pipe 11 and the first inlet header 8 Unicom; the two ends of the second steam inlet pipeline 14 are connected with the steam inlet pipe 11 and the second inlet header 16 respectively; the two ends of the first row pipe 7 are respectively connected with the first The inlet header 8 communicates with the first outlet header 6; the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com