Thermostatic valve having a sleeve

A thermostatic valve and sleeve technology, applied in the field of thermostatic valves, can solve the problems of unbalanced obturators, deformation of sealing rings, weak valve design, etc., and achieve the effect of convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

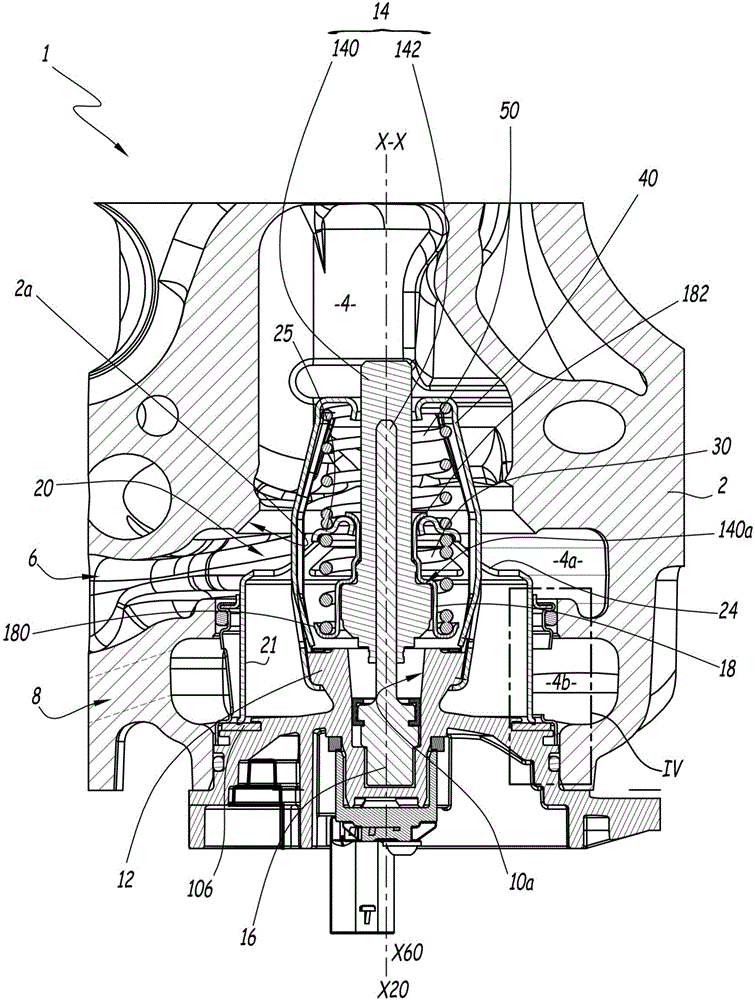

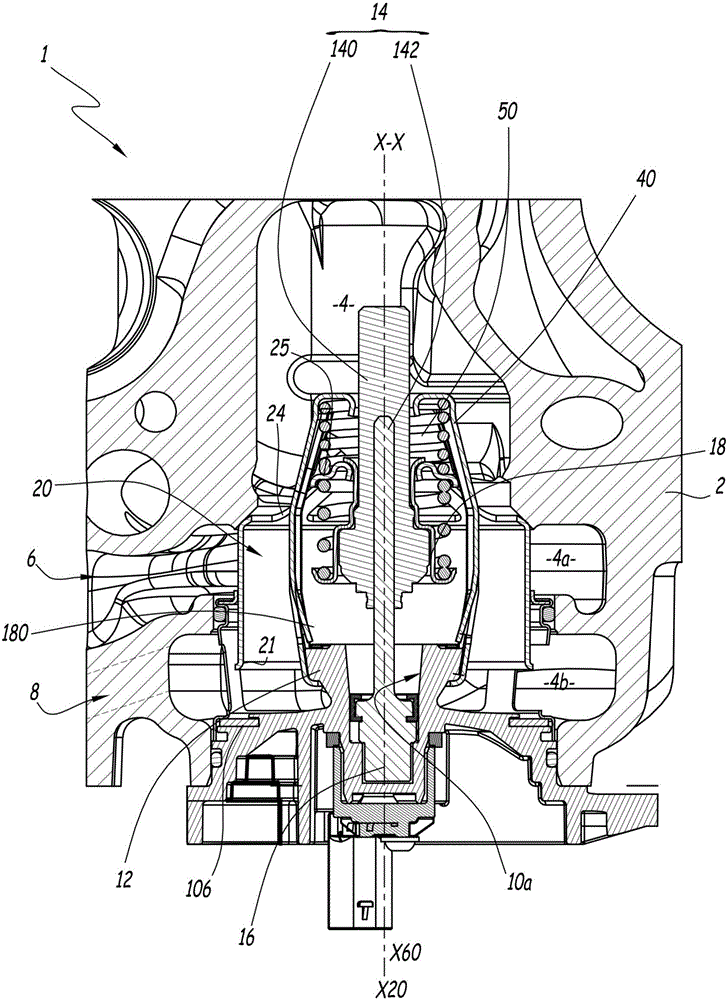

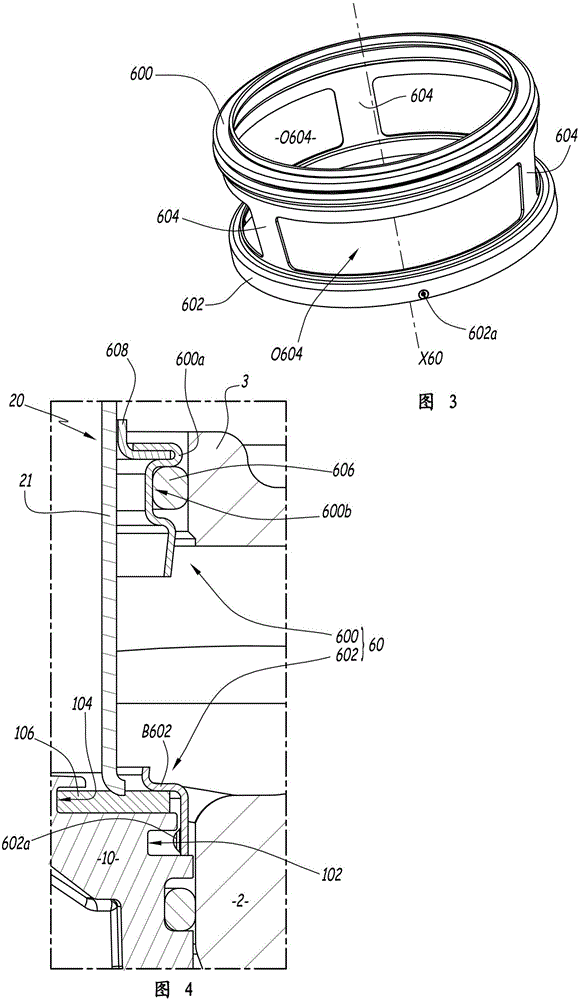

[0025] exist figure 1 In Fig. 4, a thermostat 1 is shown capable of regulating and controlling the circulation of cooling fluid. In this context, fluid means a liquid, or even a two-phase mixture. The valve 1 is used, for example, in a cooling circuit for cooling an internal combustion engine of a vehicle.

[0026] The valve 1 comprises a valve body 2 for guiding fluid. The body 2 defines a communication central duct 4 for fluid to flow therethrough. The central duct 4 extends along the longitudinal axis X-X.

[0027] In the following part of the specification, the terms "high / upper", "low / lower", "top / upper" and "bottom / lower" shall be used relative to the longitudinal axis X-X in figure 1 and figure 2 explained in the structure. exist figure 1 and figure 2 Among them, the central pipe 4 extends downward to the bottom, and includes a first chamber 4A and a second chamber 4B located below the chamber 4A. The valve body 2 delimits two further ducts 6 and 8 which open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com