Water-cooled wall gasification furnace adopting natural circulation and forced circulation separately and cooling method

A technology of forced circulation and natural circulation, applied in the field of water-cooled wall gasifier and cooling, can solve the problems of water-cooled wall easy to burn, maintenance quality cannot be guaranteed, and maintenance is difficult

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

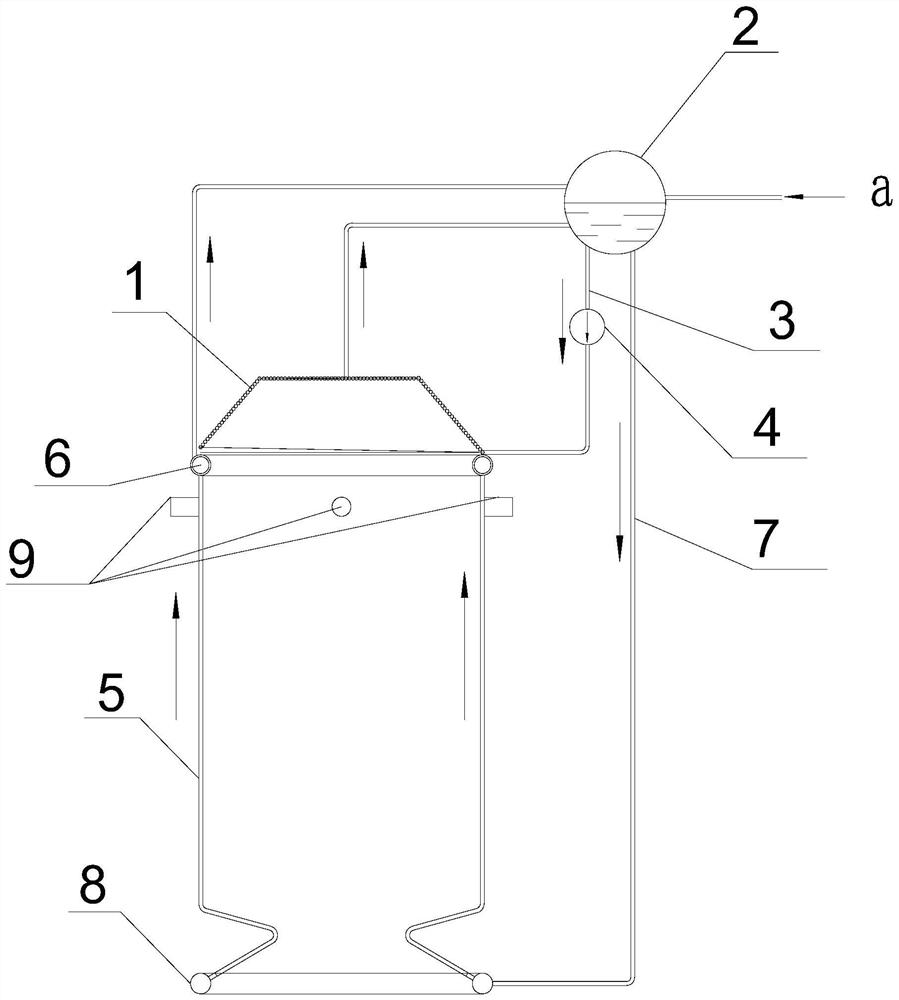

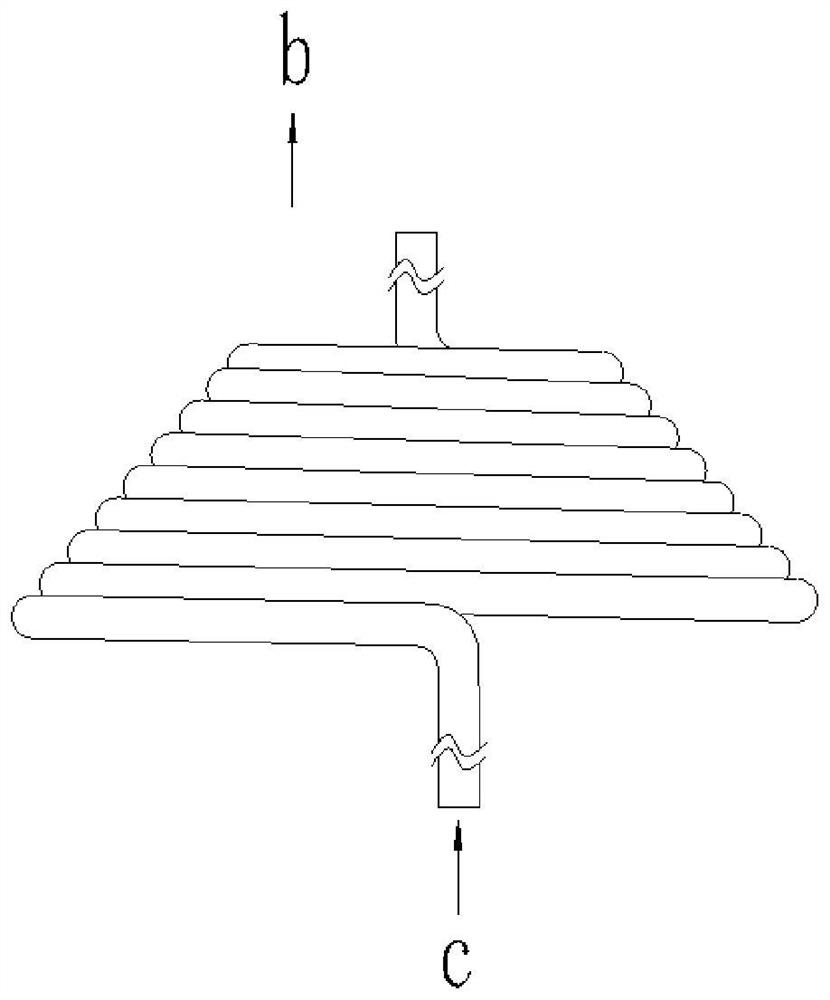

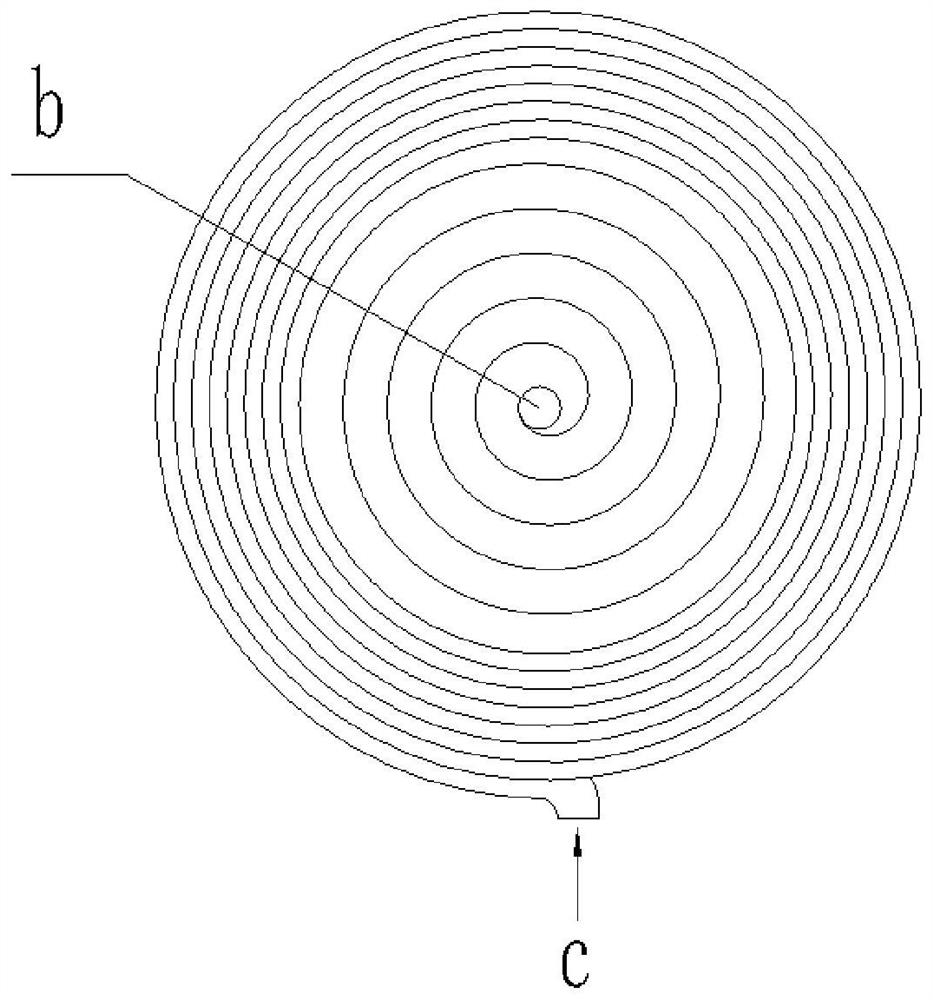

[0041] Specific implementation mode one: combine Figure 1 to Figure 3 Describe this embodiment mode, a water-cooled wall gasifier using natural circulation and forced circulation separately in this embodiment, the water-cooled wall gasifier device includes a gasifier body, and the gasifier body includes a circular platform section water-cooled wall 1. The water cooling wall 5, the upper header 6 and the lower header 8 in the cylindrical section, the water cooling wall 1, the upper header 6, the water cooling wall 5 in the cylindrical section and the lower header 8 in the circular table section are coaxially arranged in sequence from top to bottom in the vertical direction;

[0042] The water cooling wall 1 of the circular platform section is located at the top of the gasifier, and the water cooling wall 1 of the circular platform section is a hollow circular frustum-shaped structure with an open bottom. The water cooling wall 1 of the circular platform section is an independen...

specific Embodiment approach 2

[0045] Specific implementation mode two: combination Figure 1 to Figure 3 Describe this embodiment, the height of the conical section water wall 1 of this embodiment is h 1 , the height h of the water-cooled wall 5 of the cylindrical section 2 , satisfy h 2 > h 1 , and h 2 =(5~20)h 1 . Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0046] Specific implementation mode three: combination Figure 1 to Figure 3 Describe this embodiment, the generatrix length L of the conical section water-cooled wall 1 of this embodiment satisfies L=(1.15~3)h 1 . Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

[0047] Specific implementation mode four: combination Figure 1 to Figure 3 Illustrate this embodiment, the quantity of the steam drum 2 of this embodiment is one or two, when the quantity of steam drum 2 is one, the same steam drum 2 is connected with the cylindrical section water cooling wall 5 and the round table section water cooling wall 1; When the number of drums 2 is two, the water cooling wall 5 of the cylindrical section and the water cooling wall 1 of the conical section are respectively connected to the corresponding independent steam drums 2 . In this way, the water-cooled wall 5 of the cylindrical section and the water-cooled wall 1 of the conical section can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com