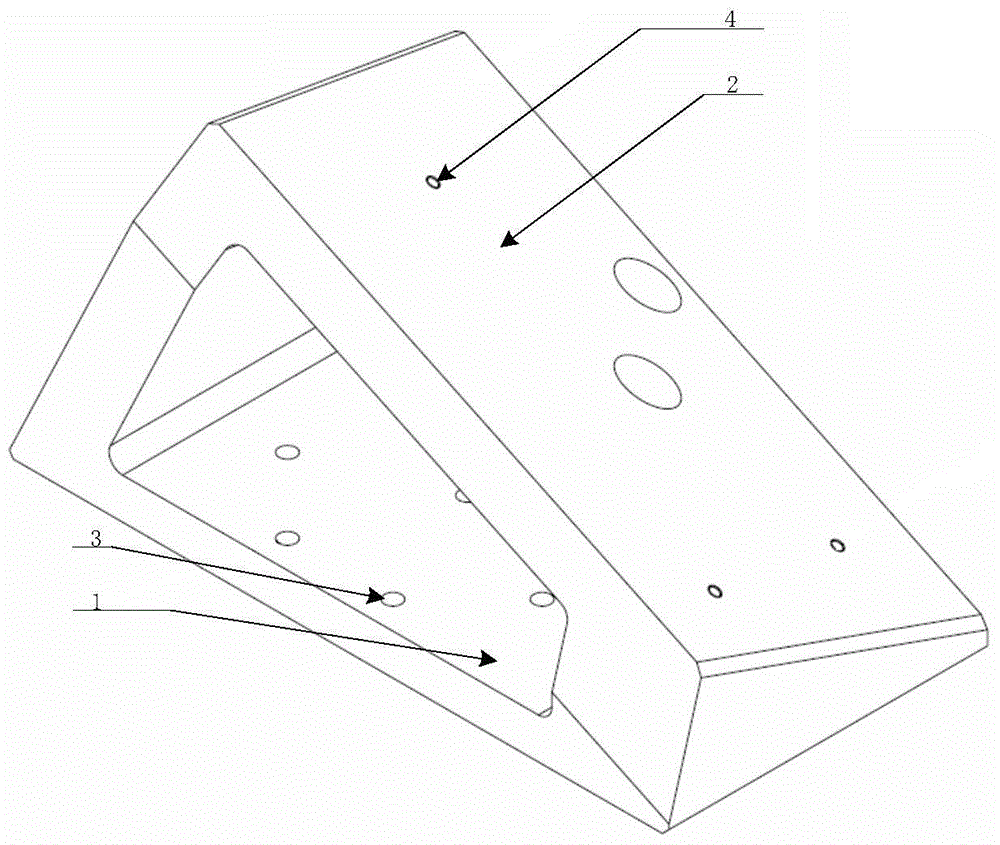

Tool used for single-axis vibration vector decomposition

A technology of vector decomposition and tooling, which is applied to measuring devices, vibration testing, and testing of machine/structural components, etc., can solve the problems of reducing resource usage and consuming test time, and achieve the effect of improving work efficiency and shortening test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

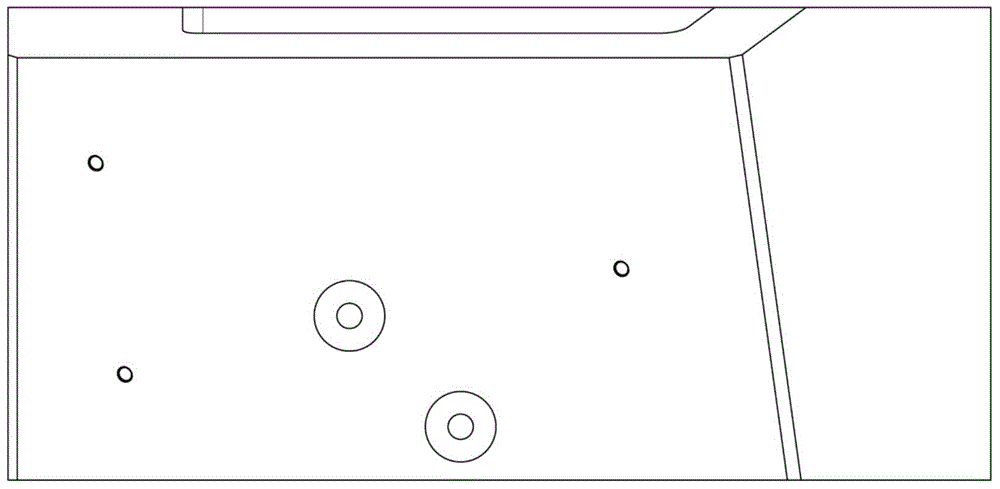

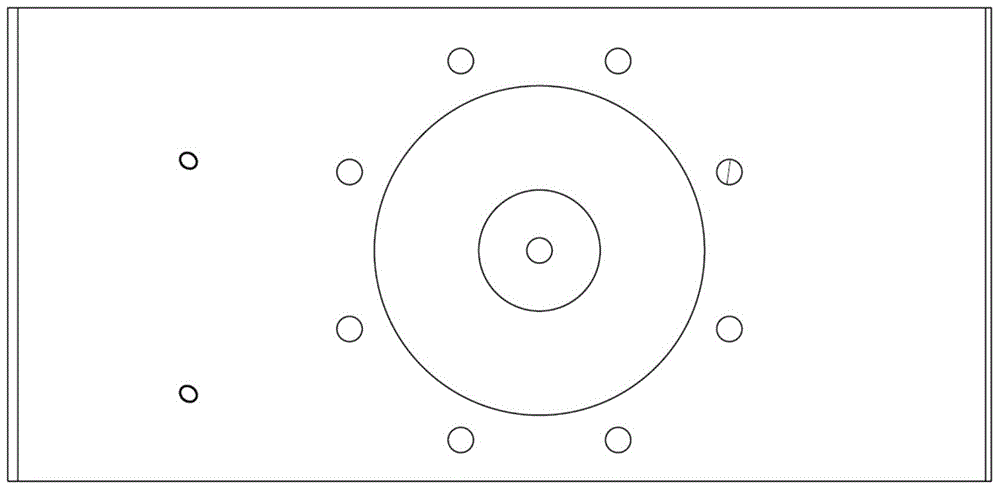

[0016] Use this tooling to select products for testing, let the space unit vector be Then its projection size on the X axis is The angle between this vector and the X-axis is The projection size on the Y axis is The angle between this vector and the Y axis is The projection size on the Z axis is The angle between this vector and the Z axis is

[0017] The ratio of the vibration response of the test product in the three directions of X, Y, and Z is required to be X:Y:Z=1:0.71:1.12. Therefore, it can be concluded that the angles between the uniaxial vibration vector and the three axes of the product are respectively Through the actual vibration test of the tool, the measured three-axis response ratio is X:Y:Z=1:0.9:1.13. Therefore, the tool can guarantee the test accuracy and meet the test requirements of single-axis excitation and three-axis response.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com