Solar cell module and production method thereof

A technology for solar cells and solar cells, applied in the field of solar cells, can solve problems such as easily broken grid cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0072] The preparation method of the solar cell assembly of an embodiment, comprises the following steps:

[0073] S10. Provide a battery cutting sheet, the battery cutting sheet is cut from a solar battery sheet, and the battery cutting sheet includes a plurality of front electrodes arranged at intervals along the length direction of the battery cutting sheet and a plurality of back surfaces arranged at intervals along the length direction of the battery cutting sheet electrode.

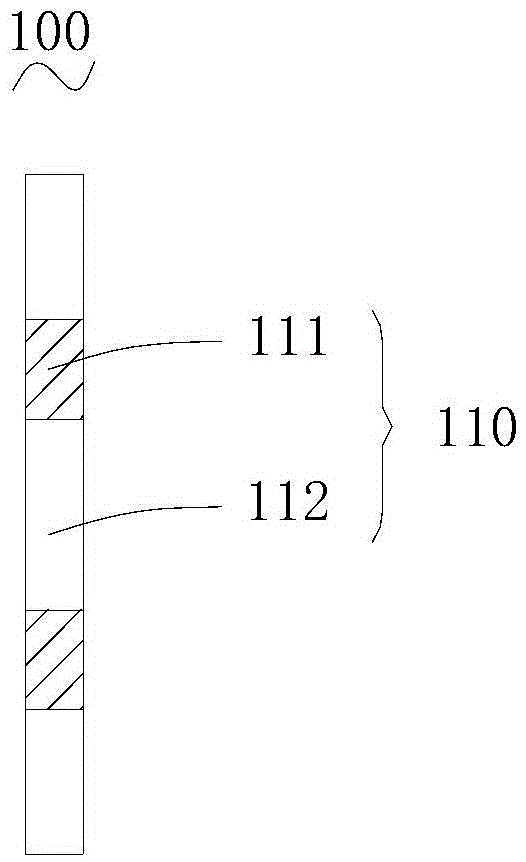

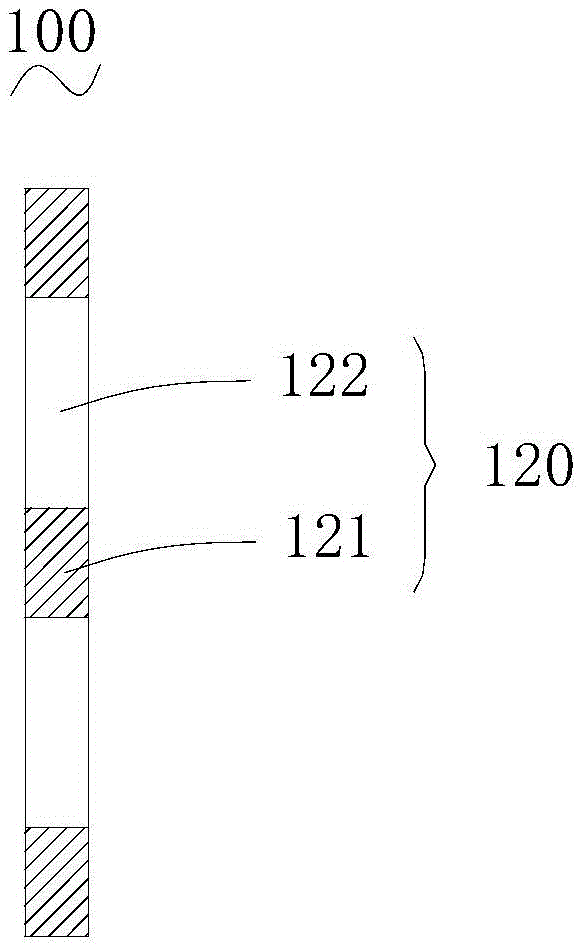

[0074] S20, providing a connecting piece, the connecting piece includes a first surface opposite to the front electrode and a second surface opposite to the back electrode.

[0075] S30. Connect the front electrode to the first surface, form alternately arranged first connection regions and first non-connection regions on the first surface, connect the back electrodes of adjacent battery cut sheets to the second surface, and Alternately arranged second connection regions and second non-connection r...

Embodiment 1

[0096] See Figure 10 and Figure 11 The battery cutting sheet 200 that forms the solar cell module of this embodiment is formed by cutting the solar battery sheet into two equal parts. The back electrodes 220 are arranged at intervals along the length direction of the battery dicing sheet 200 . Both the front electrodes 210 and the back electrodes 220 are arranged at equal intervals.

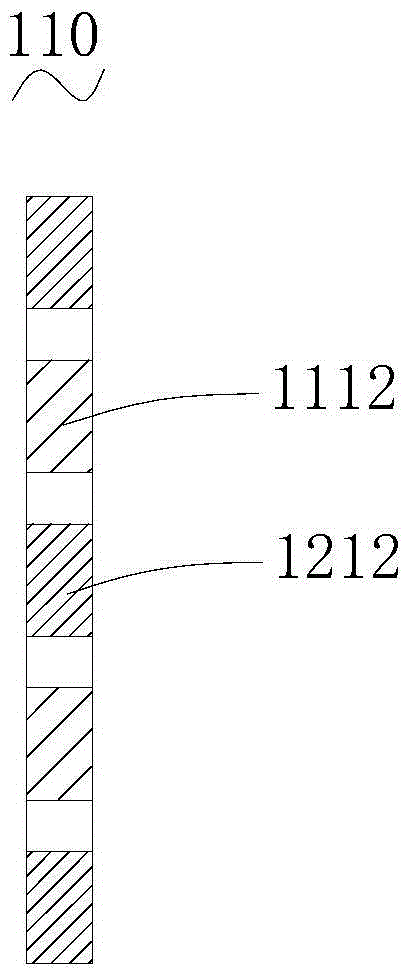

[0097] Welding the front electrode 210 to the first connection area 111 on the first surface 110 of the connector 100, and then welding the back electrode 220 of the adjacent cell cut sheet 200 to the second connection area 121 on the second surface 120 of the connector 100 welding to obtain two battery cut sheets 200 overlapping in series, such as Figure 12 shown.

[0098] In this embodiment, the width of the back electrode 220 of the left battery cutting sheet 200 is slightly larger than the width of the front electrode 210 of the right battery cutting sheet 200, and the width of the con...

Embodiment 2

[0101] See Figure 13 and Figure 14 , the cell dicing sheet 300 constituting the solar cell module of this embodiment is cut in half from the solar cell sheet. The battery cutting sheet 300 includes a front electrode 310 and a back electrode 320 each extending along the length direction of the battery cutting sheet 300 . The front electrode 310 and the back electrode 320 are respectively located at edge positions of opposite ends of the battery cutting sheet 300 .

[0102] See Figure 15 , the connector 400 of this embodiment includes a first surface 410 connected to the front electrode and a second surface 420 connected to the back electrode. Alternately arranged first connection regions 411 and first non-connection regions 412 are arranged on the first surface 410 . Alternately arranged second connection regions 421 and second non-connection regions 422 are arranged on the second surface 420 . The projection of the first non-connected area 412 on the first surface 410 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com