A preparation method of single-layer nano-thin film memristor with LTCC green ceramic tape as substrate

A technology of nano-film and green ceramic tape, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for information processing, and can solve the problems of memristor materials being hard, commercial production not yet realized, and hardware experiments unable to be carried out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

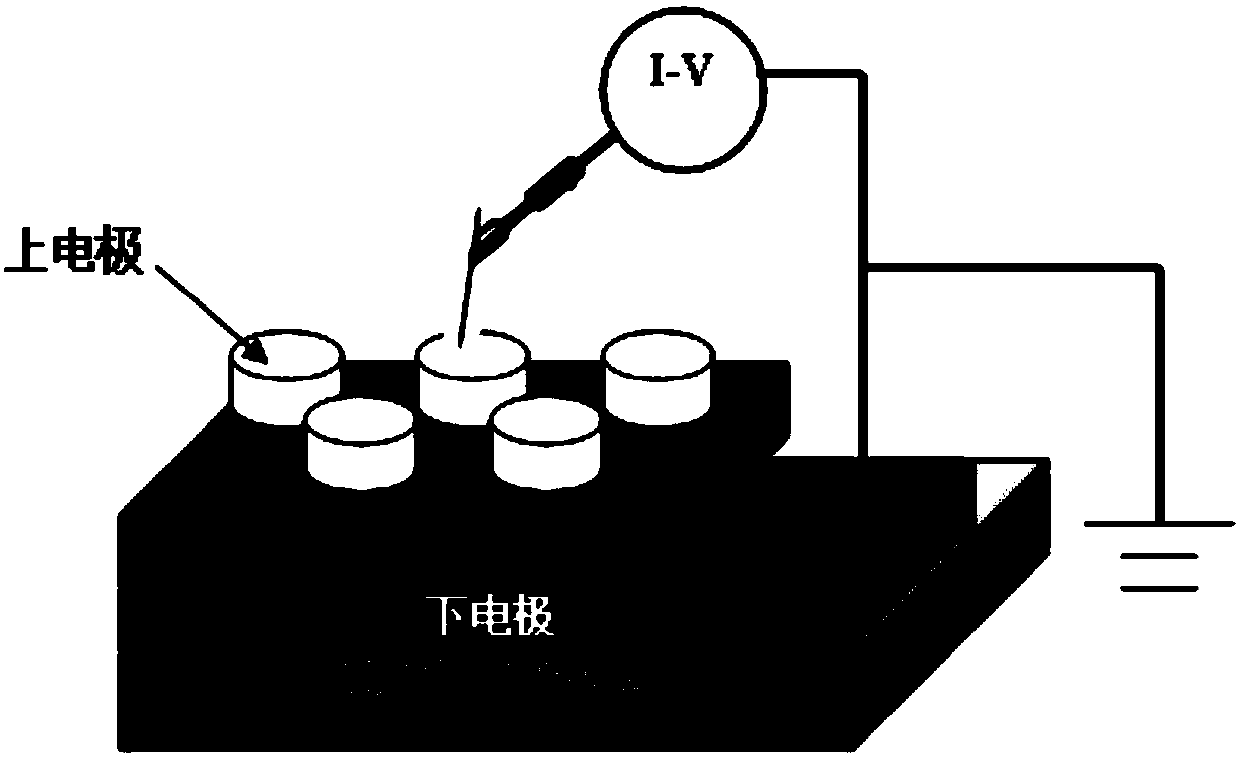

[0109] Adopt the same preparation method of single-layer nanometer film memristor, adopt pulsed laser deposition PLD or magnetron sputtering method to use Au, Ag, Pt to plate electrode, this preparation method comprises the following steps:

[0110] Step 1, with Ba(Ti 1-y x y )O 3-y(X=Mg, Zn, Ca) is used as the target material, and the pulsed laser deposition PLD or magnetron sputtering method is used to coat the LTCC raw ceramic tape with the lower electrode Pt or Au in advance to form a resistive layer. The thickness of the coating is 10-990nm, then heat-treated at 700-900°C for 10-30 minutes;

[0111] In the second step, the target material is Au, Ag or Pt, using pulsed laser method or magnetron sputtering method, in Ba(Ti 1-y x y )O 3-y A layer of upper electrode is plated on the nano film.

[0112] 3, embodiment 13 adopts and embodiment 1 Ba(Ti 1-y x y )O 3-y The raw material formula of the target is the same; moreover, a layer of upper electrode is plated with I...

Embodiment 1

[0119] Preparation of Ba(Ti 1-y x y )O 3-y The raw material formula of the target is: Ba(NO 3 ) 2 : Ti(OC 4 h 9 ) 4 : X(NO 3 ) 2 =100:99:1 (molar ratio).

Embodiment 2

[0121] Preparation of Ba(Ti 1-y x y )O 3-y The raw material formula of the target is: Ba(NO 3 ) 2 : Ti(OC 4 h 9 ) 4 : X(NO 3 ) 2 =100:98:2 (molar ratio).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com