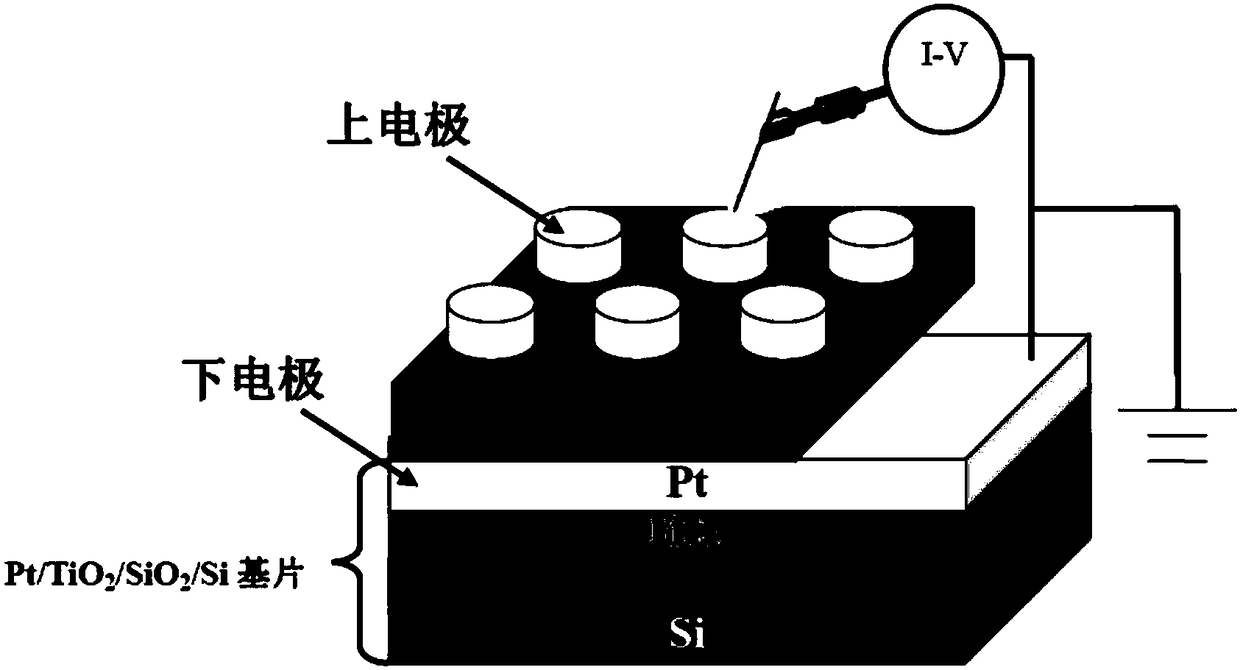

Preparation method of single-layer resistance variable film memristor

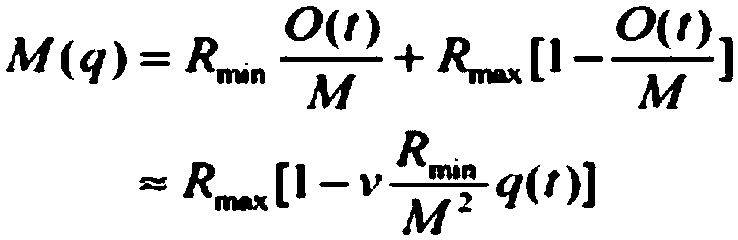

A memristor and single-layer technology, which is applied in the application field of nonlinear circuits, can solve the problems of complex preparation process, long preparation period, and few memristor models, and achieves simple preparation process, easy physical realization, and low control difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

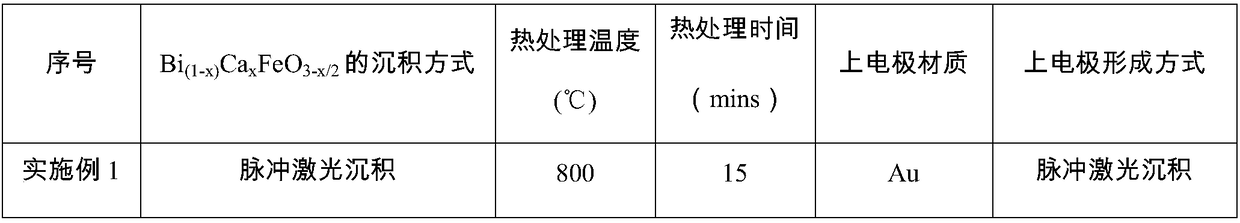

Embodiment 1

[0092] The preparation method of memristor all comprises the following steps:

[0093] The first step, prepare Bi (1-x) Ca x FeO 3-x / 2 Mixture target material, specific steps are as follows:

[0094] (1), raw material mixing:

[0095] Bi 2 o 3 : CaCO 3 : Fe 2 o 3 =99: 1: 50 (molar ratio) mixed;

[0096] Add deionized water or absolute ethanol, and grind into the mill until the particle size is below 0.08mm;

[0097] Take out and dry to obtain the mixture;

[0098] (2), Granulation:

[0099] Granulating the mixture: according to 2-5% of the mass of the mixture to be granulated, adding a polyvinyl alcohol solution with a mass percentage concentration of 2-5%, stirring evenly, passing through a 40-mesh sieve for granulation;

[0100] (3), Bi (1-x) Ca x FeO 3-x / 2 Compression molding of mixture targets:

[0101] Put the granulated material on a tablet press and press it into blocks; then, cut the resulting block into discs with a diameter of 20-150 mm and a thicknes...

Embodiment 2

[0110] In addition to preparing Bi (1-x) Ca x FeO 3-x / 2 The raw material formula of the mixture target is: Bi 2 o 3 : CaCO 3 : Fe 2 o 3 =98: 2: 50 (molar ratio) and each parameter in the following table 1;

[0111] All the other are the same as in Example 1.

Embodiment 3

[0113] In addition to preparing Bi (1-x) Ca x FeO 3-x / 2 The raw material formula of the mixture target is: Bi 2 o 3 : CaCO 3 : Fe 2 o 3 =97: 3: 50 (molar ratio) and each parameter in the following table 1;

[0114] All the other are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com