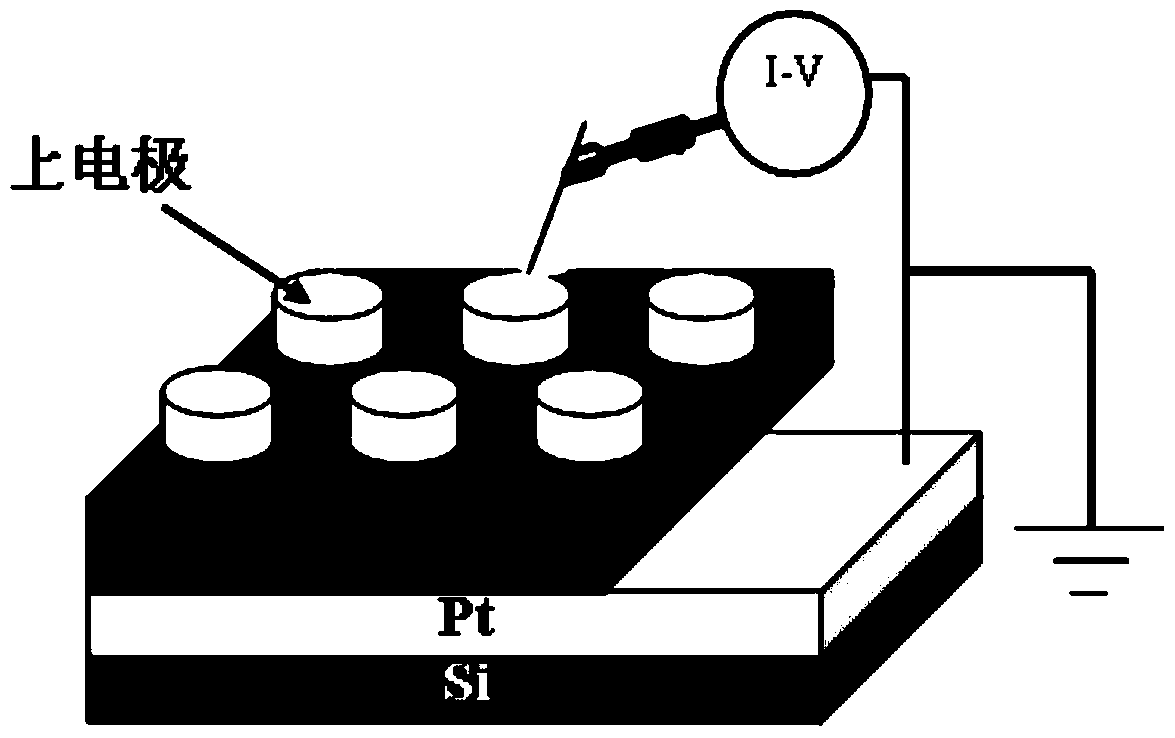

A nanoscale monolayer bi (1‑x) ca x feo 3‑x/2 Preparation method of resistive film memristor

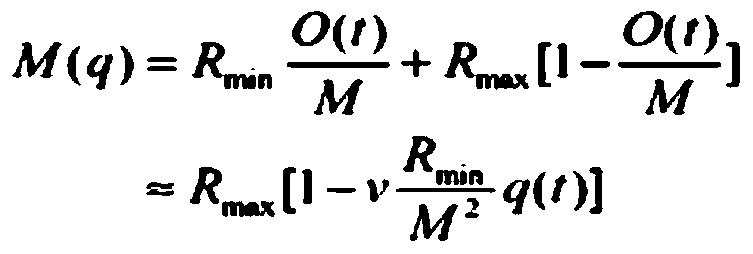

A memristor, nano-scale technology, applied in the preparation of memristor, based on the preparation field of nano-scale single-layer BiCaxFeO3-x/2 resistive film memristor, can solve the problem of long preparation period, complex preparation process, memory There are few resistor models, etc., to achieve the effects of easy physical realization, simple preparation process, and low control difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] The preparation method of memristor all comprises the following steps:

[0096] The first step, prepare Bi (1-x) Ca x FeO 3-x / 2 target, the specific steps are as follows:

[0097] (1), raw material mixing:

[0098] Bi(NO 3 ) 3 ·5H 2 o 3 : Ca(NO 3 ) 2 4H 2 o 3 : Fe(NO 3 ) 3 9H 2 o 3 =99:1:100 (molar ratio) mixed;

[0099] Dissolve the above mixture in 10%-20% dilute nitric acid, place it on a magnetic stirrer, and stir to make it completely dissolve;

[0100] (2), powder preparation

[0101] Slowly add NaOH solution dropwise to the above solution until the precipitation is complete, filter the precipitate and wash it with deionized water, add NaOH solution dropwise and adjust the pH value, put it into a reaction kettle, and put it in a constant temperature drying box that has reached a predetermined temperature of 200°C in advance , hydrothermal reaction for 24 hours;

[0102] After the hydrothermal reaction, the reactor was naturally cooled to room te...

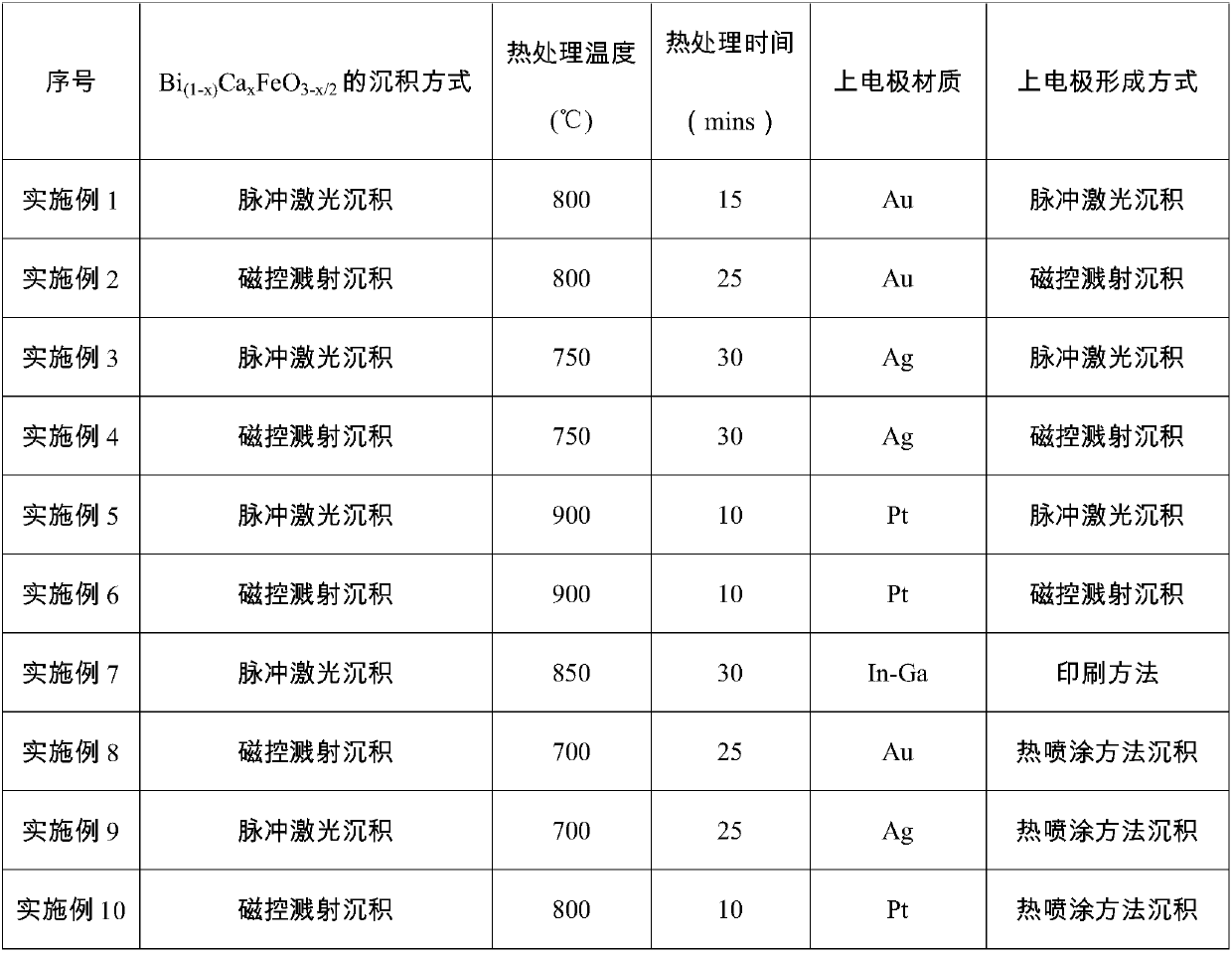

Embodiment 2

[0115] In addition to preparing Bi (1-x) Ca x FeO 3-x / 2 The raw material formula of the target is:

[0116] Bi(NO 3 ) 3 ·5H 2 o 3 : Ca(NO 3 ) 2 4H 2 o 3 : Fe(NO 3 ) 3 9H 2 o 3 =98: 2: 100 (molar ratio) and each parameter in the following table 1;

[0117] All the other are the same as in Example 1.

Embodiment 3

[0119] In addition to preparing Bi (1-x) Ca x FeO 3-x / 2 The raw material formula of the target is:

[0120] Bi(NO 3 ) 3 ·5H 2 o 3 : Ca(NO 3 ) 2 4H 2 o 3 : Fe(NO 3 ) 3 9H 2 o 3 =97: 3: 100 (molar ratio) and each parameter in the following table 1;

[0121] All the other are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com