A based on sr(ti 1‑x mg x )o 3‑x Preparation method of single-layer nano-film memristor

A nano-thin film and memristor technology, which is applied in the field of preparation of single-layer nano-thin film memristor, can solve the problems of complex manufacturing process, harsh process conditions, harsh conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

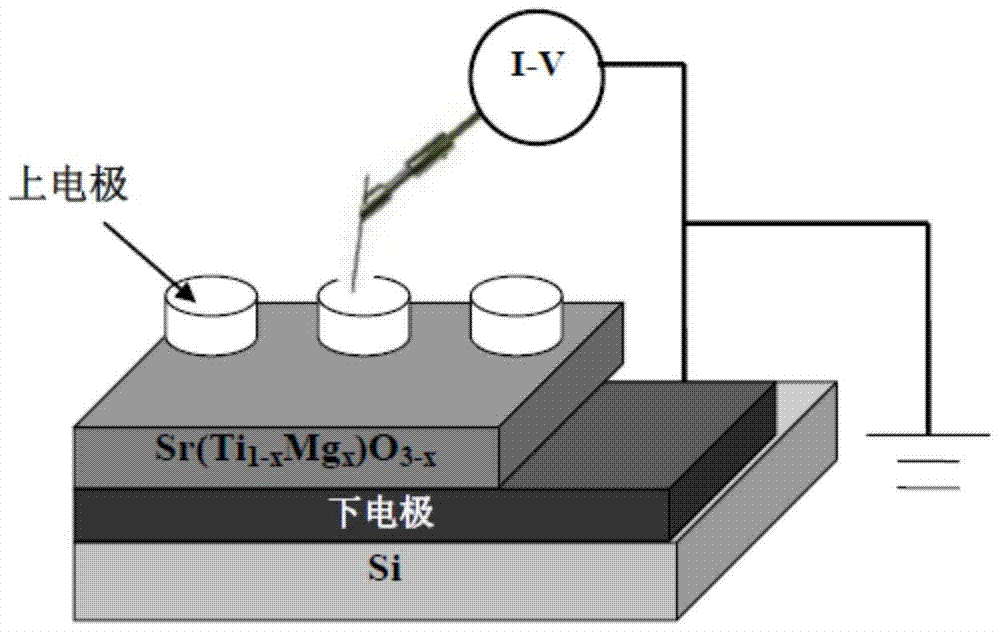

[0169] Concrete preparation method comprises the following steps:

[0170] The target material is Au, Ag or Pt, and Au, Ag or Pt is deposited on the above-mentioned chemical composition of Sr(Ti) by thermal spraying method. 1-x Mg x )O 3-xOn the single-layer ceramic nano film, the upper electrode is prepared;

[0171] Finally, heat treatment at 700-900°C for 10-30 minutes to obtain a chemical composition of Sr(Ti 1-y x y )O 3-y On the single-layer ceramic nano film, the finished product is obtained. The electrode thickness is 10nm-50um.

Embodiment 1

[0174] Preparation of Sr(Ti 1-x Mg x )O 3-x The raw material formula of the target is: Sr(CH 3 COO) 2 :C 16 h 36 o 4 Ti:Mg(CH 3 COO) 2 4H 2 O=100:99:1 (molar ratio).

Embodiment 2

[0176] Preparation of Sr(Ti 1-x Mg x )O 3-x The raw material formula of the target is: Sr(CH 3 COO) 2 :C 16 h 36 o 4 Ti:Mg(CH 3 COO) 2 4H 2 O=100:98:2 (molar ratio).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com