Photovoltaic temperature control junction box

A junction box and photovoltaic technology, applied in the direction of photovoltaic power generation, photovoltaic modules, electrical components, etc., can solve the problems of affecting the power transmission of photovoltaic power generation, the decline of SCT tube insulation performance, and the decrease of elastic modulus, so as to avoid uneven heating and prevent The effect of maintaining low resistance when the temperature is too high or too low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

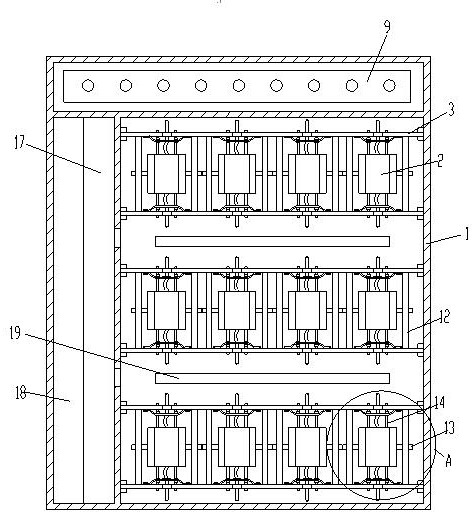

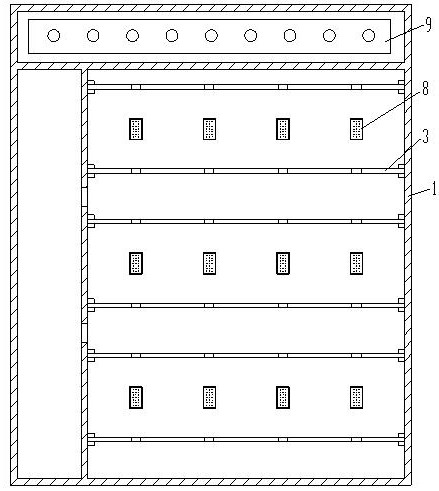

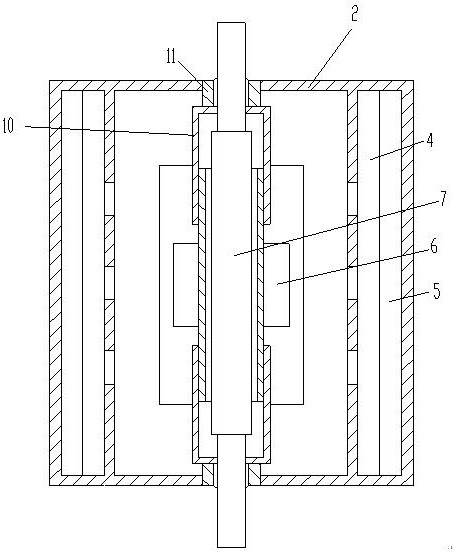

[0030] The technical characteristics of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0031] A photovoltaic temperature control junction box in this embodiment includes a box body 1 with a box door, a number of cable terminals and a junction box body 2 for accommodating the cable terminals are arranged in the box body 1, and the junction box body 2 has an opening And this also has a closed cover on the opening, the cable terminal is arranged in the junction box body 2 and; the box body 1 is provided with some fixed plate groups, the fixed plate groups include two parallel fixed plate 3, the fixed plate 3 Inserted in the box body 1 and the junction box body 2 is located between the two fixed plates 3 of the same fixed plate group; the two connecting cables at the cable terminal are EPR cables, and the SCT tube 7 is sleeved on the cable terminal; The inner two sides of the junction box body 2 are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com