Back plate, preparation method thereof, backlight module and display device

A technology of backplane and photoresist, which is applied in the direction of photolithographic exposure device, optics, and optomechanical equipment, etc., can solve the problems of increasing the production cost of thick copper metal wiring, copper oxidation, and increasing the resistance of copper metal wiring, etc. Achieve the effects of improving bonding yield, avoiding oxidation, and reducing the number of times of heating and curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

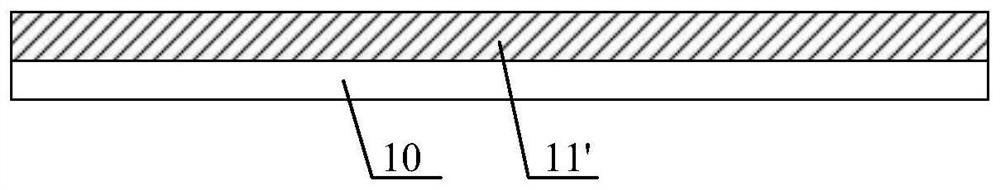

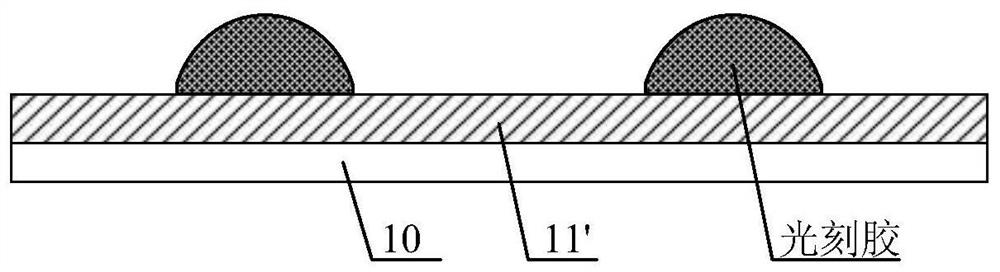

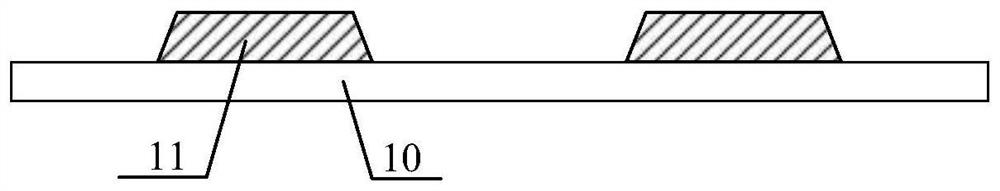

[0072] figure 2 It is a schematic diagram of the preparation method of the backplane of the embodiment of the present invention. The preparation method of the backboard includes:

[0073] S1: using a mask exposure process to form an insulating structure layer with grooves on the substrate, the grooves are used to accommodate metal wiring;

[0074] S2: repeating the step of forming the sub-metal layer including the ashing process and the wet etching process multiple times to form the metal wiring in the trench.

[0075] In one embodiment, the sidewalls of the trench are perpendicular to the surface of the substrate.

[0076] In one embodiment, the depth of the trench is greater than 3um.

[0077] In one embodiment, the step of forming the sub-metal layer includes:

[0078] depositing a metal film on the substrate formed with the trench;

[0079] forming a photoresist layer with a flat surface on the metal thin film;

[0080] Performing ashing treatment on the photoresist...

no. 2 example

[0126] The second embodiment of the present invention proposes a method for preparing a backplane. The difference from the first embodiment is that in the second embodiment, in order to obtain 3um thick copper metal traces, the number of repetitions of the sub-metal layer forming steps is 2 times, therefore, in this embodiment, S2 specifically includes: executing S21-S24 sequentially for the first time, respectively obtaining the following Figure 4a , Figure 4b , Figure 4c , Figure 4d with Figure 4e structure shown. Execute S21~S24 sequentially for the second time, and obtain the following Figure 5a , Figure 5b , Figure 5c , Figure 5d with Figure 5e structure shown.

[0127] Figure 6c-2 , Figure 6d-2 with Figure 6e-2 They are schematic structural diagrams during the process of forming the third sub-metal layer in the second embodiment. In this embodiment, the method for preparing the backplane may further include S3: forming a third sub-metal layer on...

no. 3 example

[0136] Based on the inventive concepts of the foregoing embodiments, the third embodiment of the present invention provides a backlight module. The backlight module includes the backplane formed by the aforementioned embodiments, and also includes Mini-LEDs arranged on the backplane and electrically connected to the metal wires, such as Figure 7 or Figure 8 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com