Preparation method of low-resistance surface filtering material

A surface filtration and filter material technology, which is applied in the field of preparation of low-resistance surface filter materials, can solve the problems of low ultrafine dust retention efficiency, large pore size, and easy damage to the film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

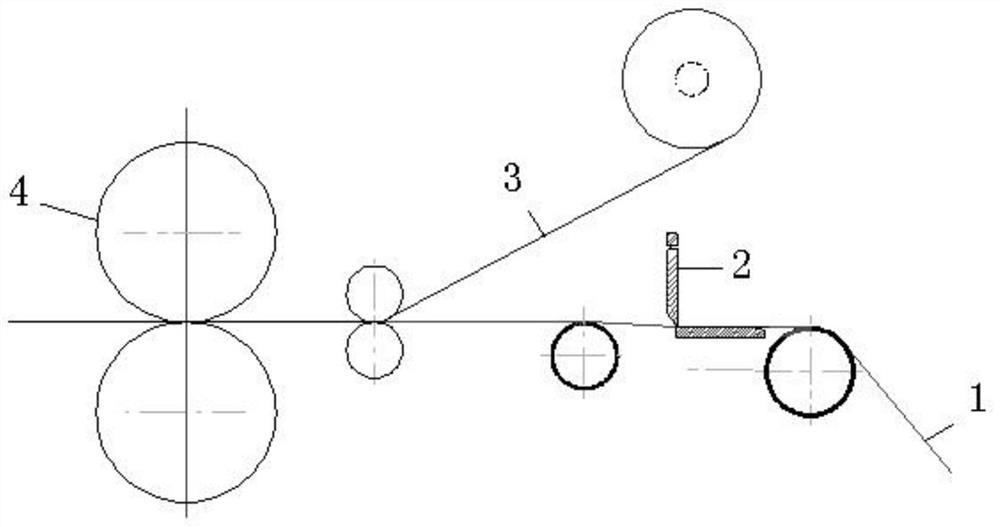

Method used

Image

Examples

Embodiment 1

[0022] Firstly, the polyester solution is made by electrospinning to obtain a grammage of 100g / m2 nanometer polyester non-woven fiber felt;

[0023] Then add the polyester fiber to the base fabric after opening, mixing, carding, laying and netting. The total weight of the base fabric is 110g / m 2 , for acupuncture or spunlace, to obtain a total grammage of 800g / m 2 Filter material plain felt;

[0024] Finally, the nano-polyester fiber felt is bonded to the surface of the plain filter felt by hot-melt compounding. The temperature of the hot pressing roller is 350°C and the pressure is 0.6MPa to obtain a dense nanofiber layer with a gradient structure. The total weight of the filter material is 600g / m 2 .

Embodiment 2

[0026] Firstly, the polyester solution is obtained by electrospinning to obtain a grammage of 50g / m2 nanometer polyester non-woven fiber felt;

[0027] Then add the polyester fiber to the base fabric after opening, mixing, carding, laying and netting. The total weight of the base fabric is 80g / m 2 , for acupuncture or spunlace, to obtain a total grammage of 450g / m 2 Filter material plain felt;

[0028] Finally, the nano-polyester fiber felt is bonded to the surface of the filter material plain felt by hot-melt compounding. The temperature of the hot pressing roller is 220°C and the pressure is 0.3MPa to obtain a filter material with a dense nanofiber layer gradient structure on the surface, with a total weight of 500g / m 2 .

Embodiment 3

[0030] Firstly, the polyester solution is produced by electrospinning method with a grammage of 10g / m2 nanometer polyester non-woven fiber felt;

[0031] Then add the polyester fiber to the base fabric after opening, mixing, carding, laying and netting. The total weight of the base fabric is 50g / m 2 , for acupuncture or spunlace, to obtain a total grammage of 200g / m 2 Filter material plain felt;

[0032] Finally, the nano-polyester fiber felt is bonded to the surface of the plain filter felt by hot-melt compounding. The temperature of the hot pressing roller is 190°C and the pressure is 0.2MPa to obtain a dense nanofiber layer with a gradient structure. The total weight of the filter material is 400g / m 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com