Coating method and coating part

A technology of coating parts and coating chambers, which is applied in the field of coating methods and coating parts, can solve the problems of affecting the air permeability of masks and improving breathing resistance, etc., and achieves the effect of good hydrophobic effect and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

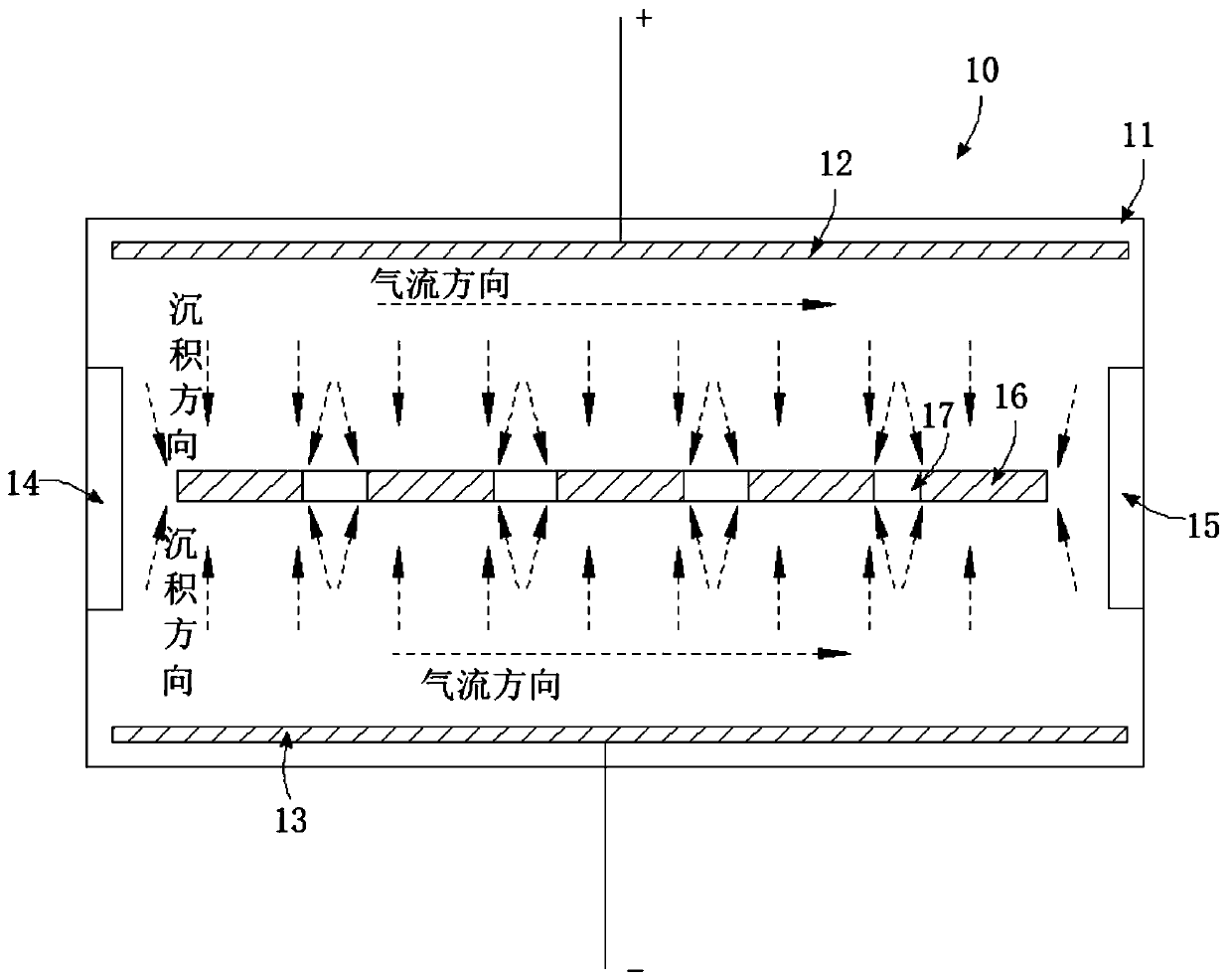

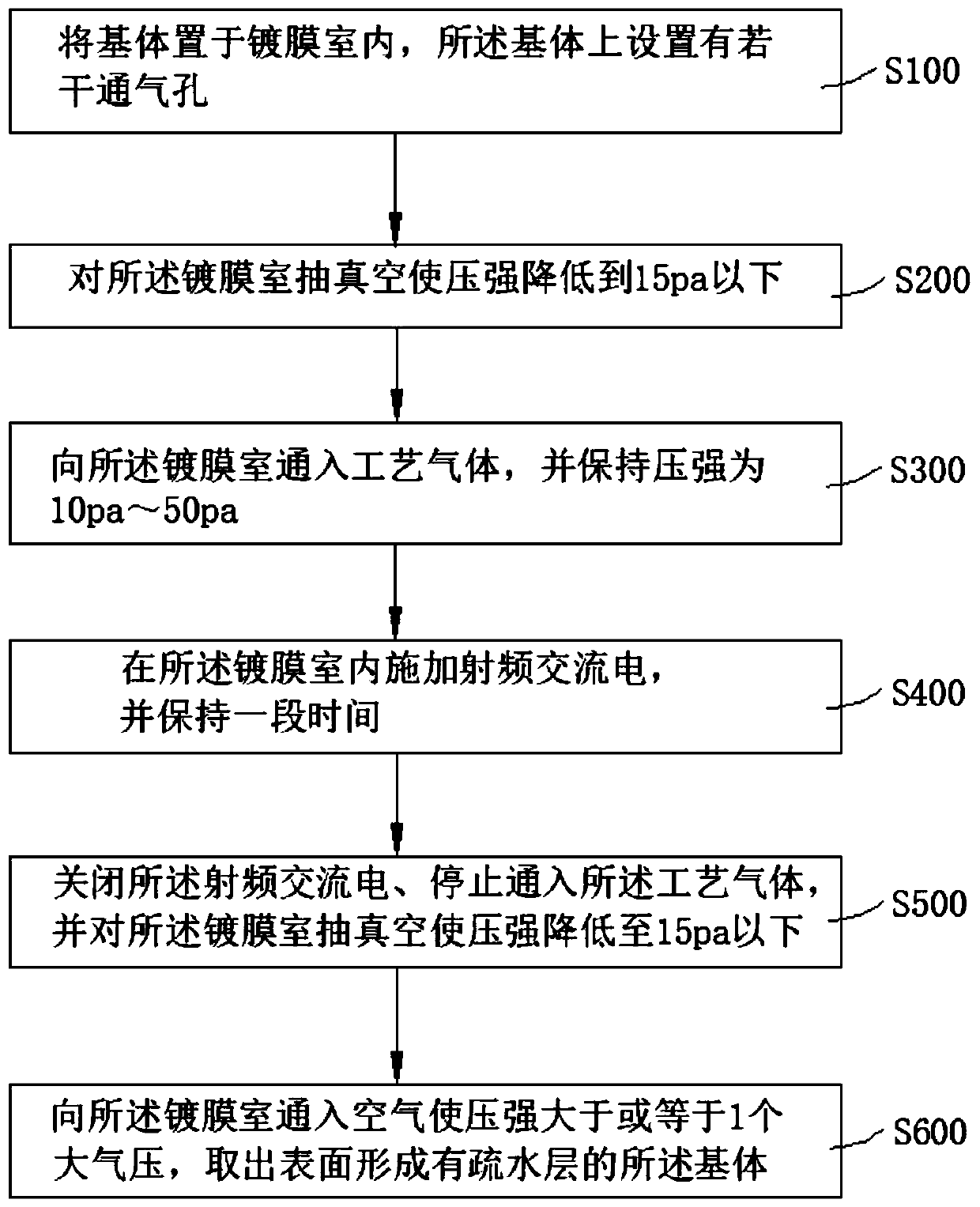

[0060] A coating method, comprising the steps of:

[0061] Arranging the nonwoven in the coating chamber 10;

[0062] Vacuumize the coating chamber 10 to reduce the pressure to below 15pa;

[0063] Feed tetrafluoromethane gas into the coating chamber 10, and keep the pressure at 20pa;

[0064] Apply radio frequency alternating current in the coating chamber 10 and keep it for 1 minute;

[0065] Turn off the radio frequency alternating current, stop feeding tetrafluoromethane gas, and vacuumize the coating chamber 10 so that the pressure is reduced to below 15pa;

[0066] Air is passed into the coating chamber 10 so that the pressure is close to the indoor atmospheric pressure, and the non-woven fabric is taken out.

[0067] The non-woven fabric is tested by the water spray test, and the test result shows that the water on the surface of the non-woven fabric forms spherical water droplets and cannot penetrate the non-woven fabric. It is proved that a hydrophobic layer is fo...

Embodiment 2

[0069] A coating method, comprising the steps of:

[0070] Ordinary dust masks are placed in the coating chamber 10;

[0071] Vacuumize the coating chamber 10 to reduce the pressure to below 15pa;

[0072] Feed octafluorocyclobutane gas into the coating chamber 10, and keep the pressure at 25pa;

[0073] Apply radio frequency alternating current in the coating chamber 10 and keep it for 1 minute;

[0074] Turn off the radio frequency alternating current, stop the introduction of octafluorocyclobutane gas, and vacuumize the coating chamber 10 to reduce the pressure to below 15 Pa;

[0075] Air is passed into the coating chamber 10 so that the pressure is close to the indoor atmospheric pressure, and the dustproof mask is taken out.

[0076] The dust mask was tested by the water spray test, and the test result showed that the water on the surface of the dust mask formed spherical water droplets, which could not pass through the dust mask. It is proved that by this coating me...

Embodiment 3

[0078] A coating method, comprising the steps of:

[0079] Ordinary dust masks are placed in the coating chamber 10;

[0080] Vacuumize the coating chamber 10 to reduce the pressure to below 15pa;

[0081] Pass oxygen and argon into the coating chamber 10 with a volume ratio of 1:1, and control the pressure in the coating chamber 10 to be 25pa, and apply radio frequency alternating current in the coating chamber 10, and keep it for 1 minute;

[0082] Vacuumize the coating chamber 10 to reduce the pressure to below 15 Pa;

[0083] Feed octafluorocyclobutane gas into the coating chamber 10, and keep the pressure at 25pa;

[0084] Apply radio frequency alternating current in the coating chamber 10 and keep it for 3 minutes;

[0085]Turn off the radio frequency alternating current, stop the introduction of octafluorocyclobutane gas, and vacuumize the coating chamber 10 to reduce the pressure to below 15 Pa;

[0086] Air is passed into the coating chamber 10 so that the pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com