Breathable cloth laminating process, sound box and automobile seat

A breathable cloth and process technology, which is applied to vehicle parts, transducer shells/cabinets/brackets, speaker transducer fixing, etc., can solve problems such as adverse environmental impact, increased recycling and processing costs, and loss of breathability of breathable cloth. for reliable bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides a breathable cloth bonding process, including the following steps:

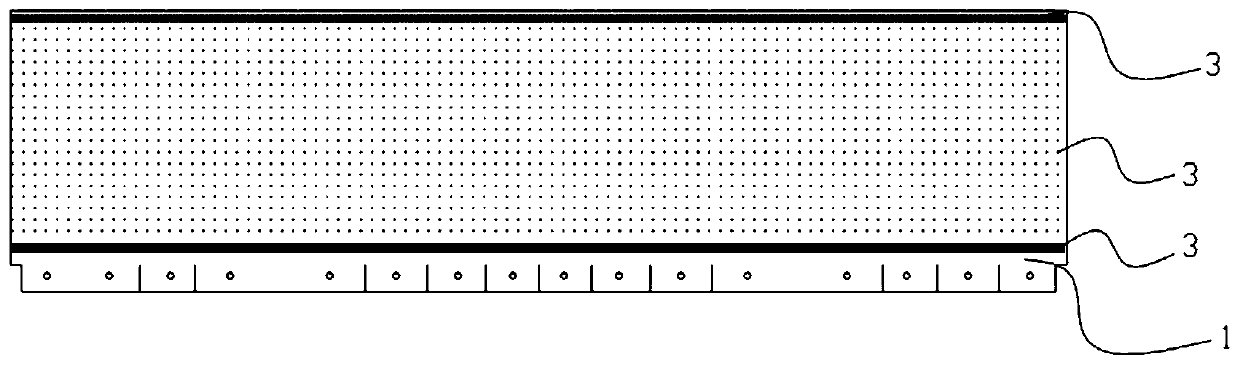

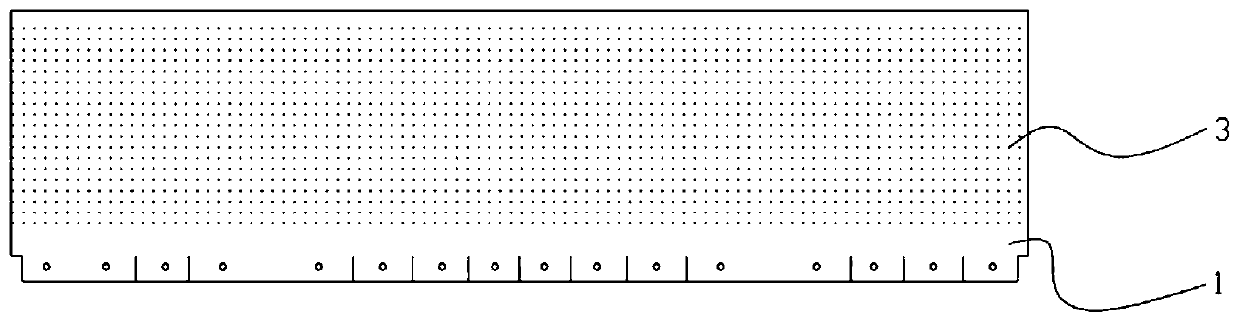

[0031] a. A plurality of rubber beads 3 are arranged on one end surface of the cloth 1 or the outside of the wrapped object; the wrapped object can be an object that needs to be wrapped with a breathable cloth 1 such as a speaker shell 4 and a car seat;

[0032] b. Lay the cloth 1 to the outside of the wrapped object, so that the glue beads 3 are located between the cloth 1 and the wrapped object; the air holes of the glue beads 3 and the cloth 1 are misplaced;

[0033] c. Heating makes the glue beads 3 into a molten state;

[0034] d. The temperature is lowered, and the glue beads 3 are re-solidified so that the cloth 1 is bonded to the wrapped object.

[0035] Compared with the prior art, the present invention uses the glue beads 3 to bond the cloth 1 and the wrapped object, and the glue beads 3 and the ventilation holes are misplaced, thus ensuring the reliable bonding of t...

Embodiment approach

[0039] Specifically, since the cloth 1 is soft and not easy to dispense glue, this embodiment provides an optional implementation, specifically including:

[0040] a'1. Dispensing or coating (i.e. coating) on the release film, evenly distributing multiple glue beads 3 on the release film; specifically, the area of the release film is approximately equal to the area of the cloth 1, Therefore, it is necessary to pre-set the distribution of the glue beads 3 on the release film according to the distribution of the air holes of the fabric 1, and then let the dispensing equipment dispense glue on the release film according to the above preset to form glue beads 3. Specifically, if the setting of the glue beads 3 is achieved by coating, this method can be used with reference to the structure disclosed in the patent application number 201711493921.6.

[0041] a'2. The release film is provided with an end surface of the rubber beads 3 and attached to the cloth 1 or the wrapped ob...

Embodiment 2

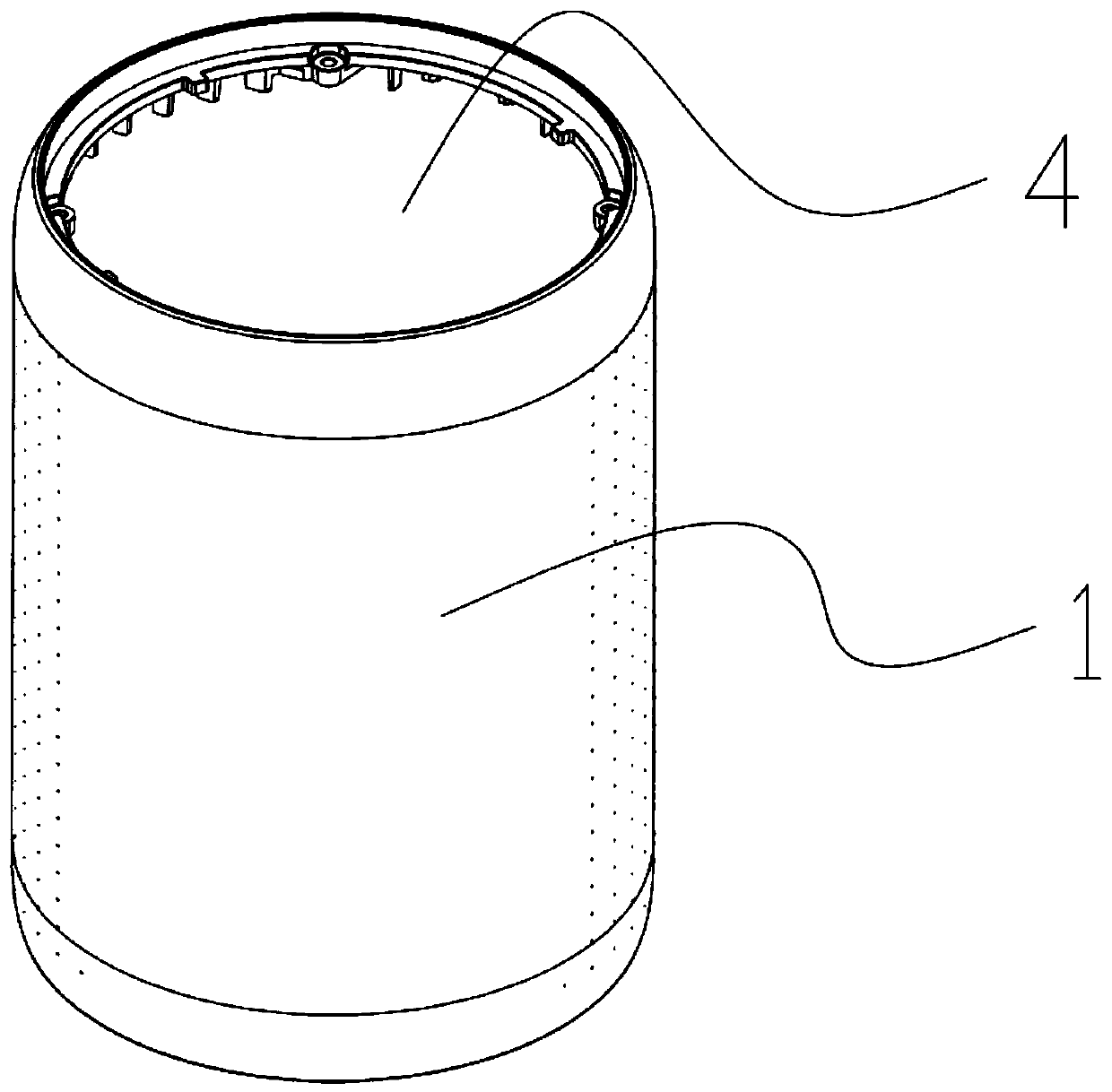

[0045] Such as image 3 and Figure 4 As shown, this embodiment provides a kind of sound box, this sound box is bonded by the method of embodiment 1, comprises cloth 1, sound box casing 4 (being the packaged thing described in embodiment 1) and is arranged on described sound box casing 4, the cloth 1 is provided with n ventilation holes at intervals, and the cloth 1 is attached to the outer wall of the sound box casing 4, n is a natural number greater than 1, and the distance between the cloth 1 and the sound box casing 4 There are also a plurality of glue beads 3 for bonding the cloth 1 and the speaker shell 4 between them, and the glue beads 3 are misplaced with the ventilation holes.

[0046] In this embodiment, since the speaker housing 4 is provided with several sound emitting holes 5, the glue beads 3 and the sound emitting holes 5 are misplaced to ensure that the glue beads 3 will not block the emission of sound.

[0047] In this embodiment, the shape of the glue bead...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com