Polypropylene film split fiber, preparation method and air filter material prepared therefrom

A polypropylene film and fiber technology, applied in fiber treatment, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of low elongation at break, poor film toughness, easy fluffing, etc., and achieve elongation at break and fibril The degree of fiberization is large, the strength and elongation at break are improved, and the effect of promoting fiber fibrillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

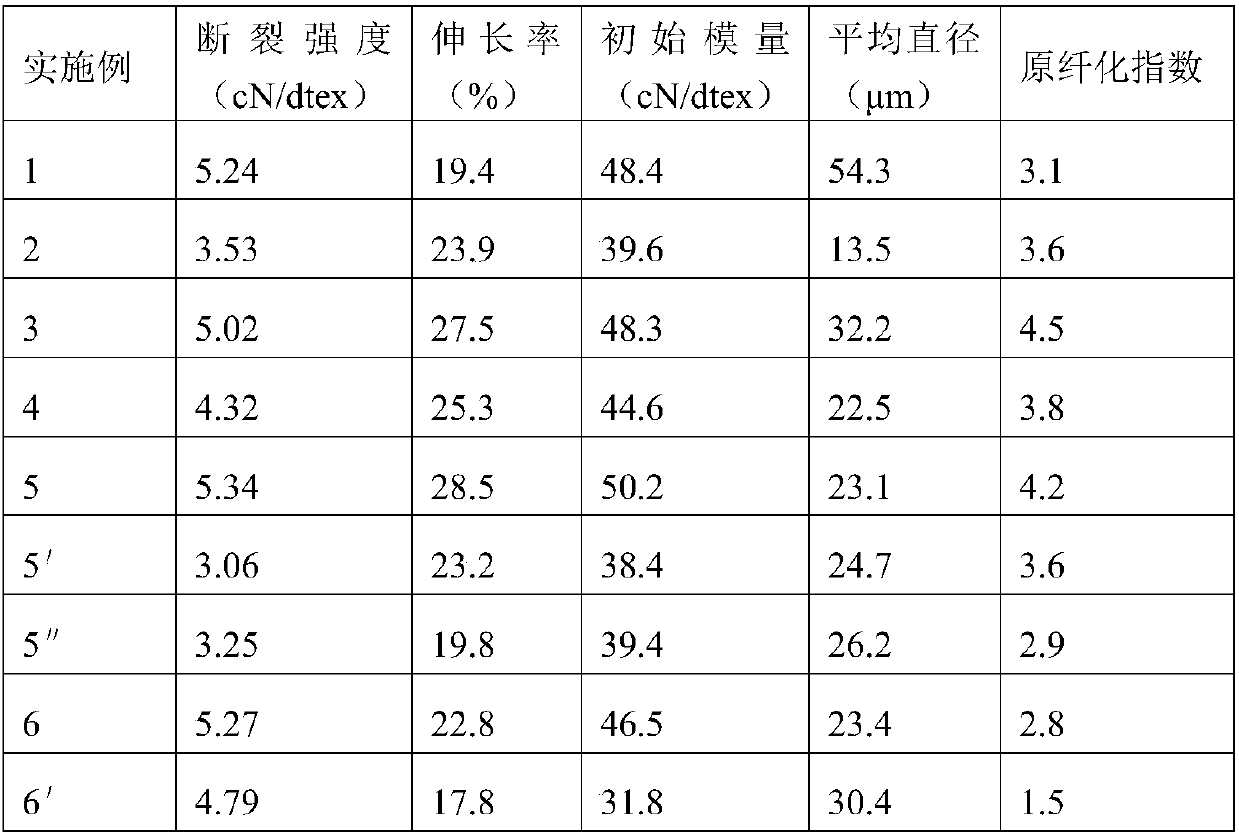

Examples

Embodiment 1

[0039] Prepare the polypropylene membrane split fiber of this embodiment according to the following steps:

[0040] (1) Surface modification of nano-silica powder with hyperbranched polyurethane resin to obtain modified nano-silica;

[0041] (2) Preparation of film masterbatch:

[0042] Layer A film masterbatch: 100 parts of PP pellets, 25 parts of POE particles, 0.5 parts of compatibilizer PP-g-MAH, 10 parts of modified nano-silica, 0.4 parts of antioxidant 1010, 0.1 parts of antioxidant 168 , light stabilizer GW-540 0.15 parts, the above-mentioned ingredients are fully mixed in a high-speed mixer at a low speed, and then melted and plasticized by a twin-screw extruder, extruded, water-cooled, air-dried, pelletized, and dried to obtain a layer of film mother grain;

[0043] B-layer film masterbatch: 100 parts of POE granules, 10 parts of modified nano-silica, 0.2 parts of antioxidant Irganox1010, 0.05 parts of light stabilizer GW-540, fully mix the above ingredients in a hi...

Embodiment 2

[0052] (1) surface modification of nano titanium dioxide and nano tourmaline powder with hyperbranched polyether resin to obtain modified nano titanium dioxide and nano tourmaline;

[0053] (2) Preparation of film masterbatch:

[0054] Layer A film masterbatch: 100 parts of PP granules, 45 parts of POE particles, 1.5 parts of compatibilizer POE-g-MAH, 10 parts of modified nano titanium dioxide, 10 parts of modified nano tourmaline powder, 0.8 parts of antioxidant 1076, 0.2 parts of antioxidant 1035, 0.3 parts of light stabilizer 770, the above ingredients are fully mixed in a high-speed mixer at a low speed, and then melted and plasticized by a twin-screw extruder, extruded, water-cooled, air-dried, pelletized, and dried to obtain A-layer film masterbatch;

[0055] B-layer film masterbatch: 100 parts of POE granules, 10 parts of modified nano-titanium dioxide, 0.4 parts of antioxidant 1076, and 0.4 parts of light stabilizer. The extruder is melted and plasticized, extruded, ...

Embodiment 3

[0064] (1) surface modification of nano-titanium dioxide and nano-silicon dioxide with hyperbranched polyamide resin to obtain modified nano-titanium dioxide and nano-silicon dioxide;

[0065] (2) Preparation of film masterbatch:

[0066] Layer A film masterbatch: 100 parts of PP granules, 75 parts of POE granules, 3.5 parts of compatibilizer PP-g-GMA, 5 parts of modified nano titanium dioxide, 10 parts of modified nano silicon dioxide, 1.2 parts of antioxidant 2246 , 0.3 parts of antioxidant 626, 9440.5 parts of light stabilizer, the above-mentioned ingredients are fully mixed in a high-speed mixer at a low speed, and then melted and plasticized by a twin-screw extruder, extruded, water-cooled, air-dried, pelletized, and dried to obtain A-layer film masterbatch;

[0067] Layer B film masterbatch: 100 parts of POE particles, 5 parts of modified nano titanium dioxide, 10 parts of modified nano silicon dioxide, 0.8 parts of antioxidant 2246, 0.2 parts of antioxidant 626, 0.05 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com