Composition for improving hydrostatic pressure resistance of fluorine-series waterproof agent and use method of composition

A technology of hydrostatic pressure resistance and composition, applied in the direction of improved hand-feeling fibers, liquid repellent fibers, fiber types, etc., can solve the problems of insufficient improvement of hydrostatic pressure resistance performance of waterproofing agents, and avoid the reduction of air permeability. , Save production costs, improve the effect of hydrostatic pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

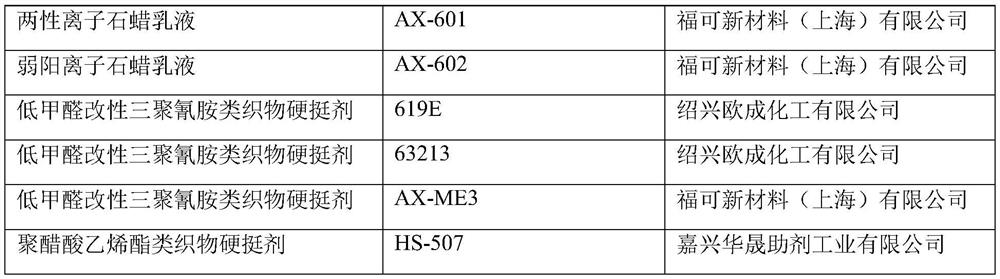

Method used

Image

Examples

Embodiment 1

[0039] Fabric Choice: 100% Polyester 300T Pongee Blue.

[0040] Choice of waterproofing agent: Fluorine C8 waterproofing agent SG-480C.

[0041] 1) Compound the paraffin emulsion AX-601 and the low-formaldehyde modified melamine fabric stiffener AX-ME3 at a mass ratio of 85:15 to obtain a hydrostatic pressure-resistant lifting composition;

[0042] 2) Prepare hydrostatic pressure-resistant finishing working solution, the formula is:

[0043] C8 waterproofing agent SG-480C 20g / L

[0044] The above hydrostatic pressure-resistant composition 10g / L

[0045] 2) padding treatment, the process is: horizontal rolling car, pressure 2.5kg, speed 6m / min, rolling rate 70%;

[0046] 3) Baking treatment: temperature 170°C, time 60s.

[0047] The hydrostatic pressure test results are shown in the following table 2 (wherein the process of formula 1 finishing fabric is the same as formula 2):

[0048] Table 2

[0049] formula storage stability 1 2 C8 waterproofing agen...

Embodiment 2

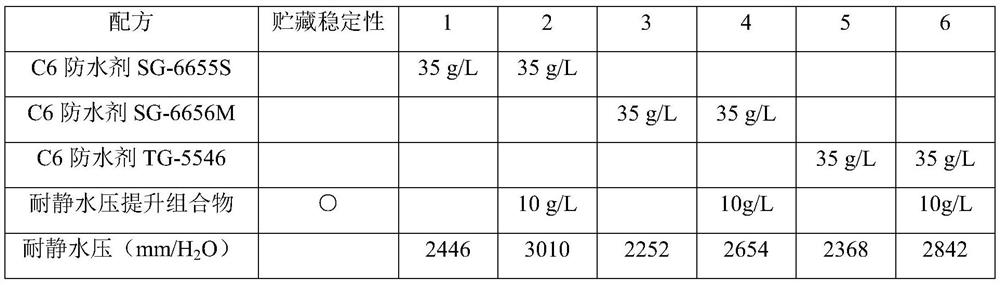

[0052] Fabric Choice: 100% Polyester 300T Pongee Blue.

[0053] Choice of waterproofing agent: fluorine C6 waterproofing agent SG-6655S, SG-6656M, TG-5546.

[0054] 1) Compound the paraffin emulsion AX-601 and the low-formaldehyde modified melamine fabric stiffener AX-ME3 at a mass ratio of 85:15 to obtain a hydrostatic pressure-resistant lifting composition;

[0055] 2) Prepare hydrostatic pressure-resistant finishing working solution, the formula is:

[0056] C6 waterproofing agent 35g / L

[0057] The above hydrostatic pressure-resistant composition 10g / L

[0058] 3) padding treatment, the process is: horizontal rolling car, pressure 2.5kg, speed 6m / min, rolling rate 70%;

[0059] 4) Baking treatment: temperature 170°C, time 60s.

[0060] The hydrostatic pressure test results are shown in the following table 3 (wherein the process of formula 1-6 finishing fabric is the same):

[0061] table 3

[0062]

[0063]

[0064] It can be seen from the results that the hydr...

Embodiment 3

[0066] The paraffin wax emulsion AX-601 and the fabric stiffening agent AX-ME3 are compounded with a mass ratio of 7:3 to obtain a water pressure-resistant composition, and the same operation as in Example 2 is repeated, and the hydrostatic pressure resistance and hand feel of the treated fabric are tested. evaluate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com