A kind of preparation method of single-layer nanometer resistive film memristor

A memristor and nano-film technology, applied in the field of nonlinear circuit applications, can solve the problems of long preparation period, high requirements, complex preparation process, etc., and achieve the effects of easy physical realization, improved resistance performance, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

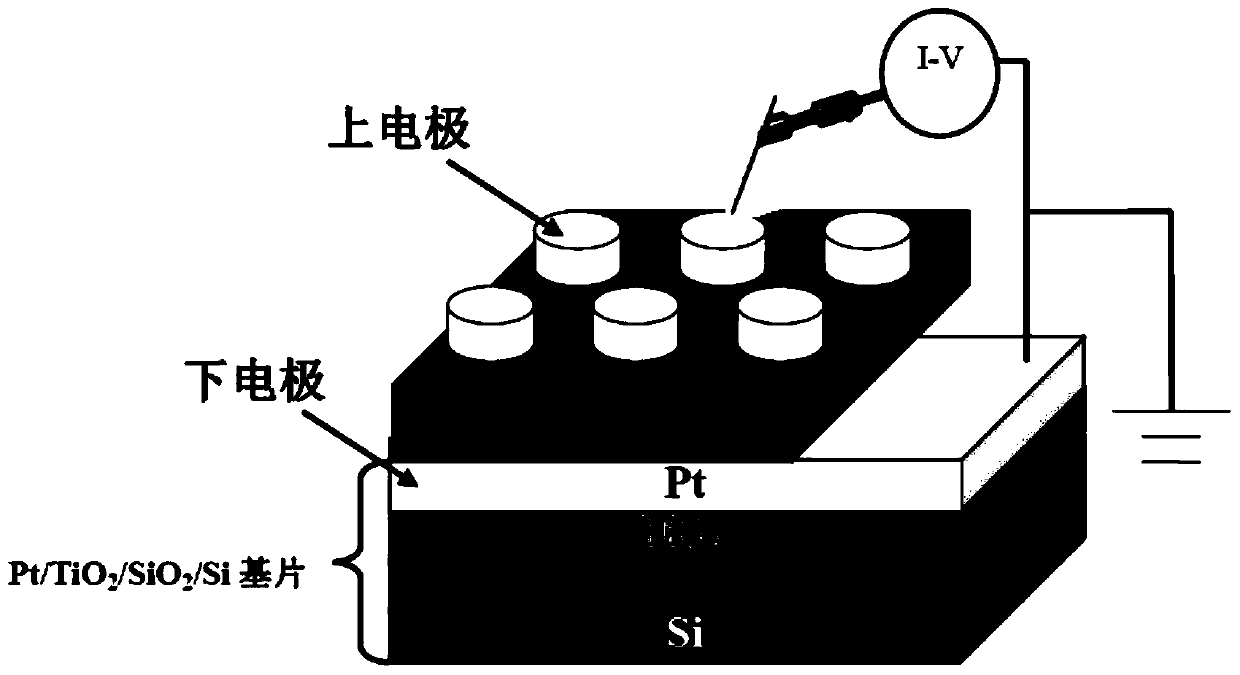

Image

Examples

Embodiment 1

[0091] The preparation method of the memristor comprises the following steps:

[0092] The first step is to prepare Bi (1-x) Ca x FeO 3-x / 2 The mixture target, the specific steps are as follows:

[0093] (1), mixing of raw materials:

[0094] will Bi 2 O 3 : CaCO 3 : Fe 2 O 3 =99:2:100 (molar ratio) mixing;

[0095] Add deionized water or anhydrous ethanol, and grind into a mill until the particle size is below 0.08mm;

[0096] Take out and dry to obtain a mixture;

[0097] (2), granulation:

[0098] The above mixture is granulated: according to 2-5% of the mass of the mixture to be granulated, a polyvinyl alcohol solution with a mass percentage concentration of 2-5% is added, and after mixing evenly, granulation is carried out through a 40-mesh sieve;

[0099] (3), Bi (1-x) Ca x FeO 3-x / 2 Compression molding of mixture targets:

[0100] The granulated material is placed on a tablet press and pressed into a block; then, the obtained block material is cut into d...

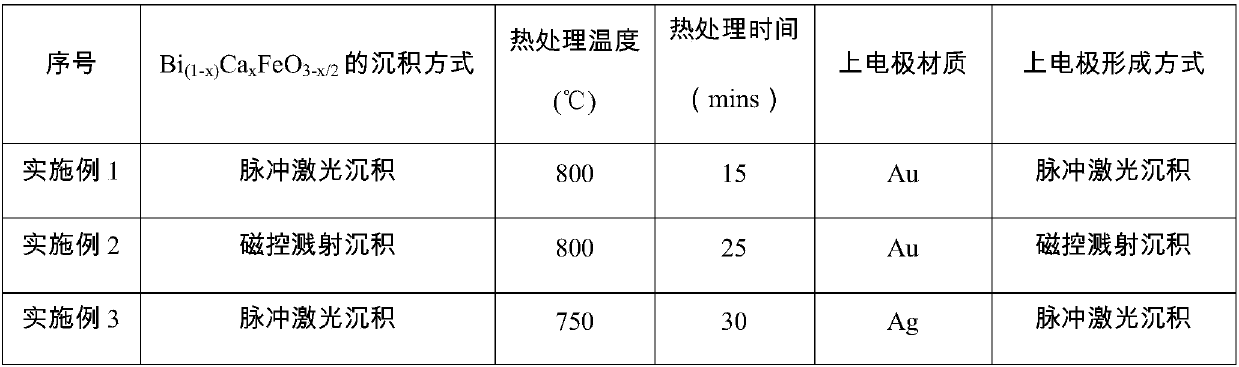

Embodiment 2

[0109] In addition to preparing Bi (1-x) Ca x FeO 3-x / 2 The raw material formula of the mixture target is: Bi 2 O 3 : CaCO 3 : Fe 2 O 3 = 98:4:100 (molar ratio), and in addition to the parameters in Table 1 below;

[0110] The rest are the same as in Example 1.

Embodiment 3

[0112] In addition to preparing Bi (1-x) Ca x FeO 3-x / 2 The raw material formula of the mixture target is: Bi 2 O 3 : CaCO 3 : Fe 2 O 3 = 97:6:100 (molar ratio), and in addition to the parameters in Table 1 below;

[0113] The rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com