Spiral Bolt Electric Heating Rod

An electric heating rod and helical technology, which is applied in the field of heating devices, can solve the problems of limited heating objects and extra stress on the occlusal position, and achieve the effect of avoiding heating and avoiding heating expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

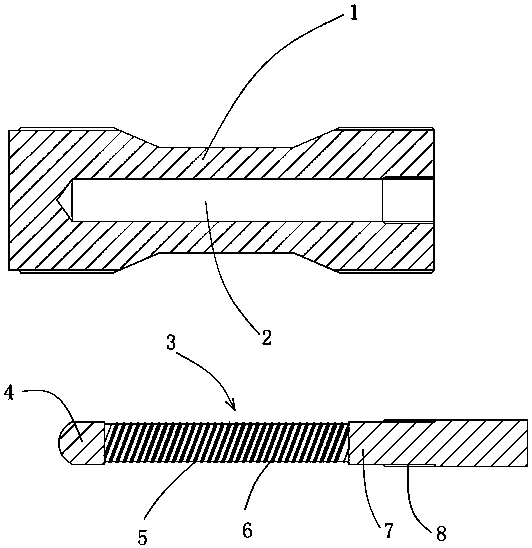

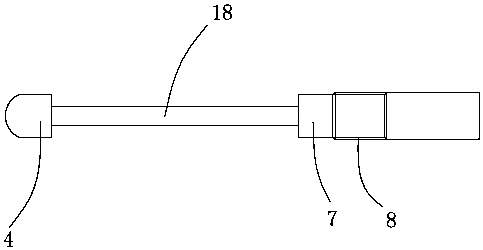

[0022] Embodiment 1: A kind of helical bolt electric heating rod (see figure 1 figure 2 ), including the front insulation section 4, the heating section and the rear insulation section 7 connected in sequence.

[0023] The electric heating rod is cylindrical as a whole, the maximum outer diameter of the front insulation section is larger than the outside diameter of the heating section, the maximum outside diameter of the rear insulation section is larger than the outside diameter of the heating section, and the maximum outside diameter of the front insulation section and the rear insulation section is the same as that of the bolt 1 The apertures of the inner hole 2 match. The front heat insulation section has a front positioning end, and the front positioning end is a round head. A connecting thread 8 is arranged on the rear heat insulation section, and an inner thread is arranged on the inner wall of the hole of the bolt inner hole, and the connecting thread and the inner...

Embodiment 2

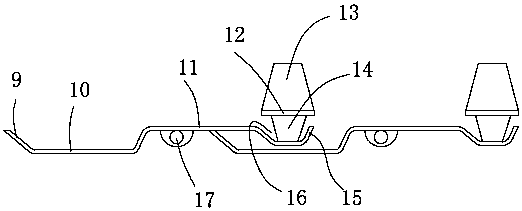

[0026] Embodiment 2: A spiral bolt electric heating rod, including a front insulation section 4 , a heating section and a rear insulation section 7 connected in sequence.

[0027] The electric heating rod is cylindrical as a whole, the maximum outer diameter of the front insulation section is larger than the outside diameter of the heating section, the maximum outside diameter of the rear insulation section is larger than the outside diameter of the heating section, and the maximum outside diameter of the front insulation section and the rear insulation section is the same as that of the bolt 1 The apertures of the inner hole 2 match. The front heat insulation section has a front positioning end, and the front positioning end is a round head. A connecting thread 8 is arranged on the rear heat insulation section, and an inner thread is arranged on the inner wall of the hole of the bolt inner hole, and the connecting thread and the inner thread are screwed together. The outer d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com