Novel solid-liquid separation sieve

A new type of solid-liquid separation technology, applied in the direction of filtration separation, separation method, mobile filter element filter, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

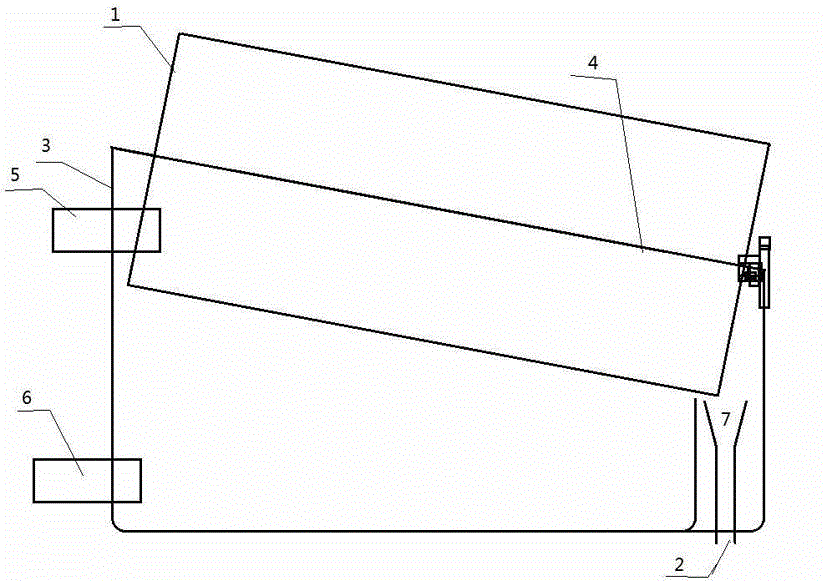

[0013] see figure 1 As shown, the present invention is provided with filter drum 1, filter screen and sump 3, and described filter drum 1 is cylindrical, wraps described filter screen in the side circumferential direction of cylinder, and the upper and lower sides of filter drum 1 Open at both ends, the filter drum 1 is provided with a center roller 4, the center roller 4 is installed obliquely on the sump 3 at a certain angle, and a motor is provided at one end of the center roller 4, which can be used at a certain speed Axial rotation, water inlet pipe 5 and outlet pipe 6 are provided on the sump 3, and the filter drum 1 is respectively connected with the water inlet pipe 5 and the outlet pipe 6 through pipes; at one end of the filter drum 1 The below is provided with a dirt collecting bucket 7. The dirt collection bucket 7 is connected to a sewage pipe 2 . The sewage to be treated enters the filter drum 1 from the high end water inlet pipe 5, and clean water and impuriti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com