A lanthanum-based phosphomolybdate catalyst and its application in catalyzing the hydrolysis of fructose to produce lactic acid

A lanthanum-based phosphomolybdate and catalyzed fructose technology, which is applied in the field of catalysis, can solve the problems of long fermentation time, large consumption of raw materials, long process flow, etc., and achieve the effect of simple preparation method and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

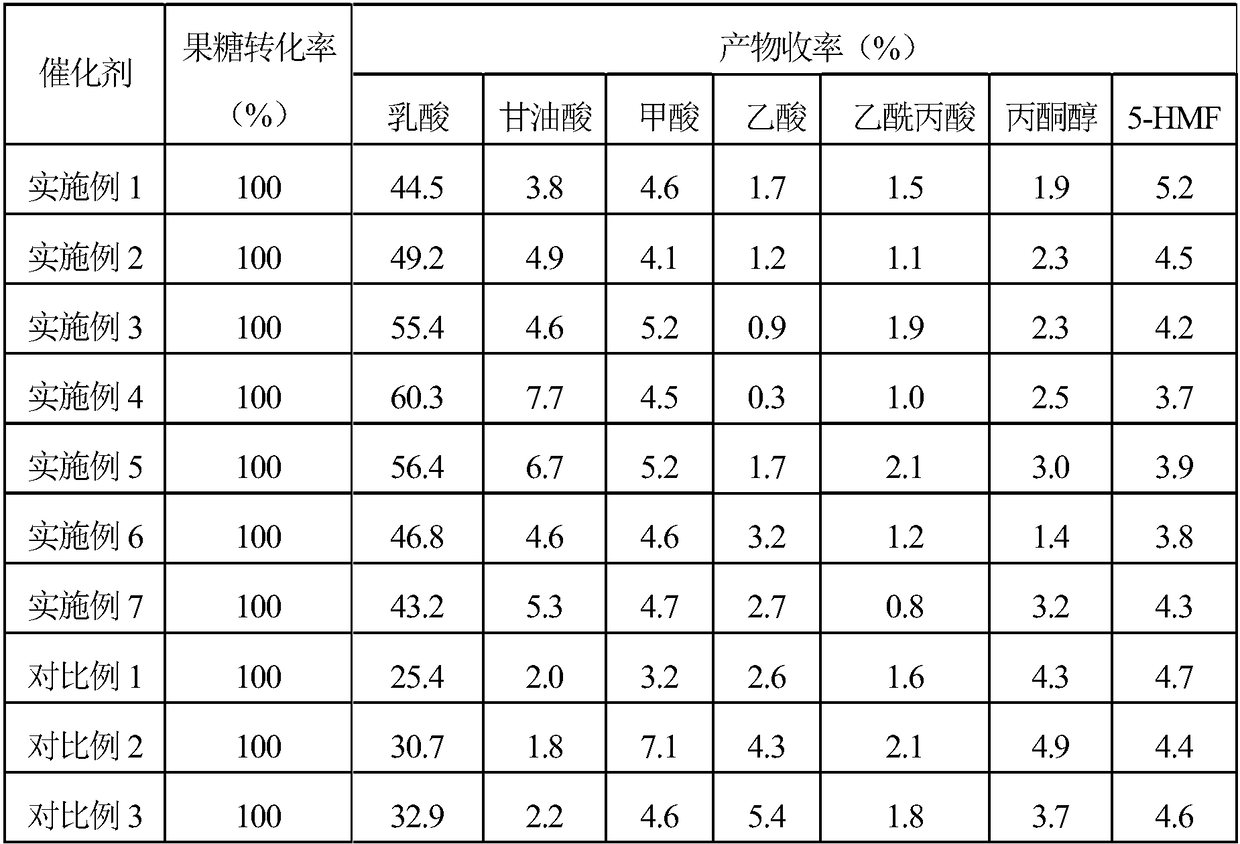

Examples

Embodiment 1

[0013] Weigh 0.56g of phosphomolybdic acid, dissolve it in 20mL of deionized water, and stir at room temperature for 30 minutes at a stirring rate of 500 rpm to obtain an aqueous solution of phosphomolybdic acid; weigh 0.12g of lanthanum nitrate and dissolve it in 20mL of deionized water, and Stir at a stirring rate of 500 rpm for 30 minutes to obtain an aqueous solution of lanthanum nitrate; under stirring conditions, the aqueous solution of lanthanum nitrate is added dropwise to the aqueous solution of phosphomolybdic acid at a rate of 2 mL / min. Raise it to 40°C and stir at a stirring rate of 800 rpm for 2 hours, then place the solution in an oven at 110°C for 12 hours, take out the solid product and grind it finely to obtain a lanthanum-based phosphomolybdate catalyst.

Embodiment 2

[0015] Weigh 0.56g of phosphomolybdic acid, dissolve it in 20mL of deionized water, and stir at room temperature for 30 minutes at a stirring rate of 500 rpm to obtain an aqueous solution of phosphomolybdic acid; weigh 0.16g of lanthanum nitrate and dissolve it in 20mL of deionized water, and Stir at a stirring rate of 500 rpm for 30 minutes to obtain an aqueous solution of lanthanum nitrate; under stirring conditions, the aqueous solution of lanthanum nitrate is added dropwise to the aqueous solution of phosphomolybdic acid at a rate of 2 mL / min. Raise it to 40°C and stir at a stirring rate of 800 rpm for 2 hours, then place the solution in an oven at 110°C for 12 hours, take out the solid product and grind it finely to obtain a lanthanum-based phosphomolybdate catalyst.

Embodiment 3

[0017] Weigh 0.56g of phosphomolybdic acid, dissolve it in 20mL of deionized water, and stir at room temperature for 30 minutes at a stirring rate of 500 rpm to obtain an aqueous solution of phosphomolybdic acid; weigh 0.20g of lanthanum nitrate and dissolve it in 20mL of deionized water, and Stir at a stirring rate of 500 rpm for 30 minutes to obtain an aqueous solution of lanthanum nitrate; under stirring conditions, the aqueous solution of lanthanum nitrate is added dropwise to the aqueous solution of phosphomolybdic acid at a rate of 2 mL / min. Raise it to 40°C and stir at a stirring rate of 800 rpm for 2 hours, then place the solution in an oven at 110°C for 12 hours, take out the solid product and grind it finely to obtain a lanthanum-based phosphomolybdate catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com