Composite strip manufacturing method and rewinding equipment

A technology for composite strips and manufacturing methods, applied in the processing field of strips such as aluminum/steel composite strips, can solve the problems of reduced steel strip surface quality, unfavorable product quality, and reduced production efficiency, so as to reduce cold rolling and cleaning process, improve market competitiveness, and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

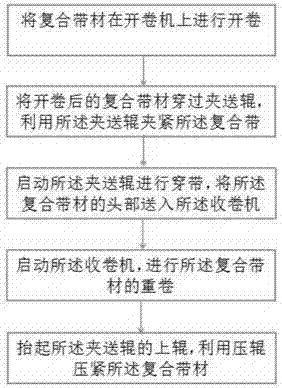

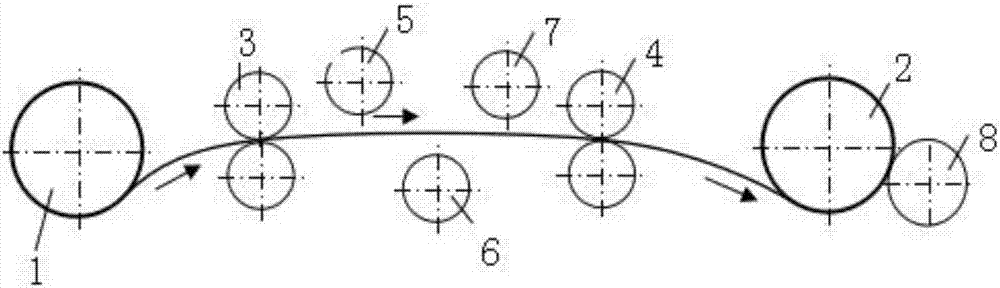

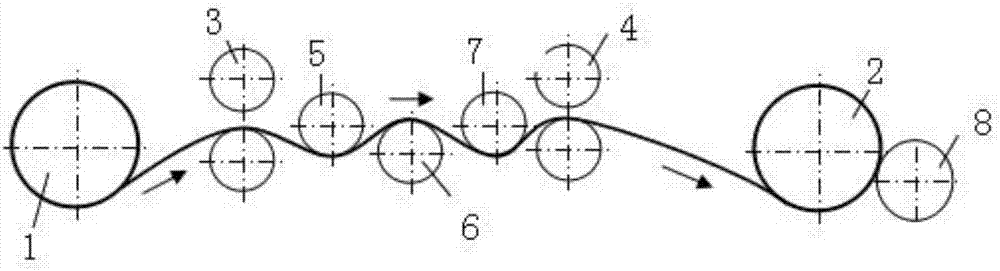

[0084] The aluminum strip with a thickness of 0.18mm and the steel strip with a thickness of 2.7mm are rolled and compounded, and the overall thickness of the aluminum and steel strip after compounding is 1.58mm. Recoiling of aluminum / steel composite strips. The aluminum / steel composite strip coil is fixed on the uncoiler 1, and the uncoiler 1 is started. The aluminum / steel composite strip passes through the front pinch roller 3 and the rear pinch roller 4 in sequence. After the aluminum / steel composite strip passes through the pinch roller completely, the pinch roller clamps the aluminum / steel composite strip. Start the pinch roller, and the head of the aluminum / steel composite strip enters the winder 2 under the action of the pinch roller, and is clamped by the winder 2 . Start winder 2 and rubber pressure roller 8. The aluminum / steel composite strip is gradually transferred from uncoiler 1 to rewinder 2. When the aluminum / steel composite strip roll on the winder 2 has t...

Embodiment 2

[0088] The aluminum strip with a thickness of 0.15mm and the steel strip with a thickness of 2.7mm are rolled and compounded, and the thickness of the aluminum and steel strip after compounding is 1.46mm. The aluminum / steel composite strip is recoiled, and the aluminum / steel composite strip coil is fixed on the uncoiler 1. Start the uncoiler 1, and the aluminum / steel composite strip passes through the front pinch belt 3 and the rear pinch belt 4 in sequence. After the aluminum / steel composite strip passes through the pinch roller completely, the pinch roller clamps the aluminum / steel composite strip. Start the pinch roller, and the head of the aluminum / steel composite strip enters the winder 2 under the action of the pinch roller, and is clamped by the winder 2 . Start winder 2 and rubber pressure roller 8. The aluminum / steel composite strip is gradually transferred from uncoiler 1 to rewinder 2. When the aluminum / steel composite strip roll on the winder 2 has three turns o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com