Bag making machine

A technology of bag making machine and frame, applied in the direction of external support, transportation packaging, packaging, etc., which can solve the problems of short service life of plastic film belts, increased trouble for users, and wire drawing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

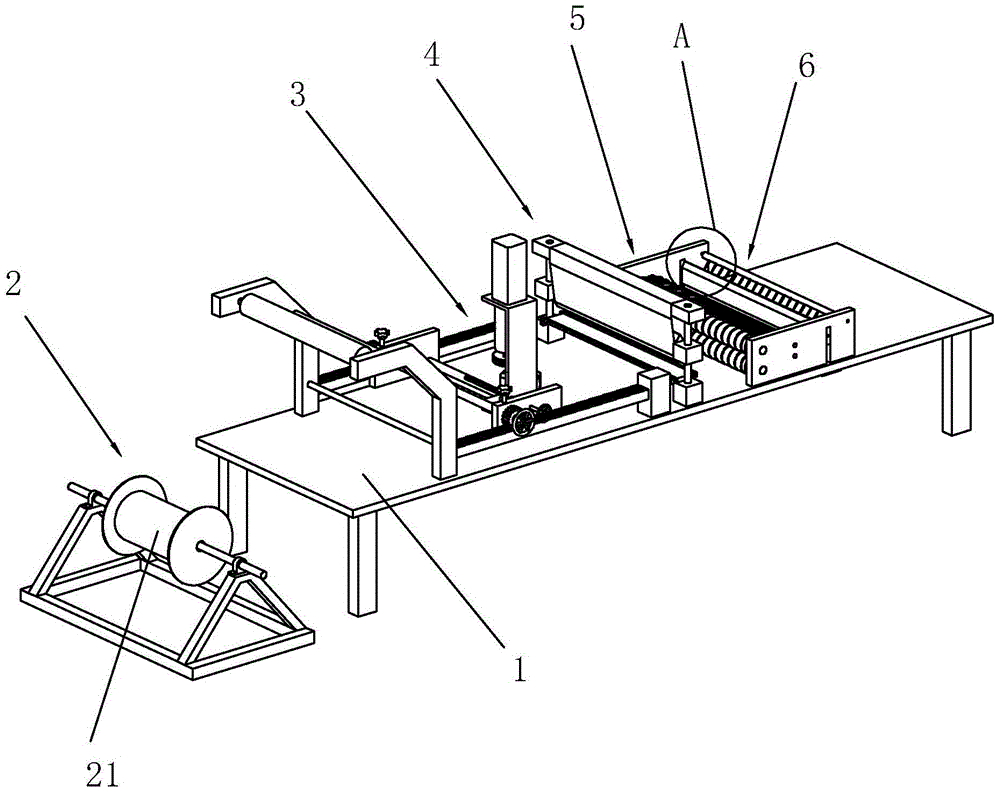

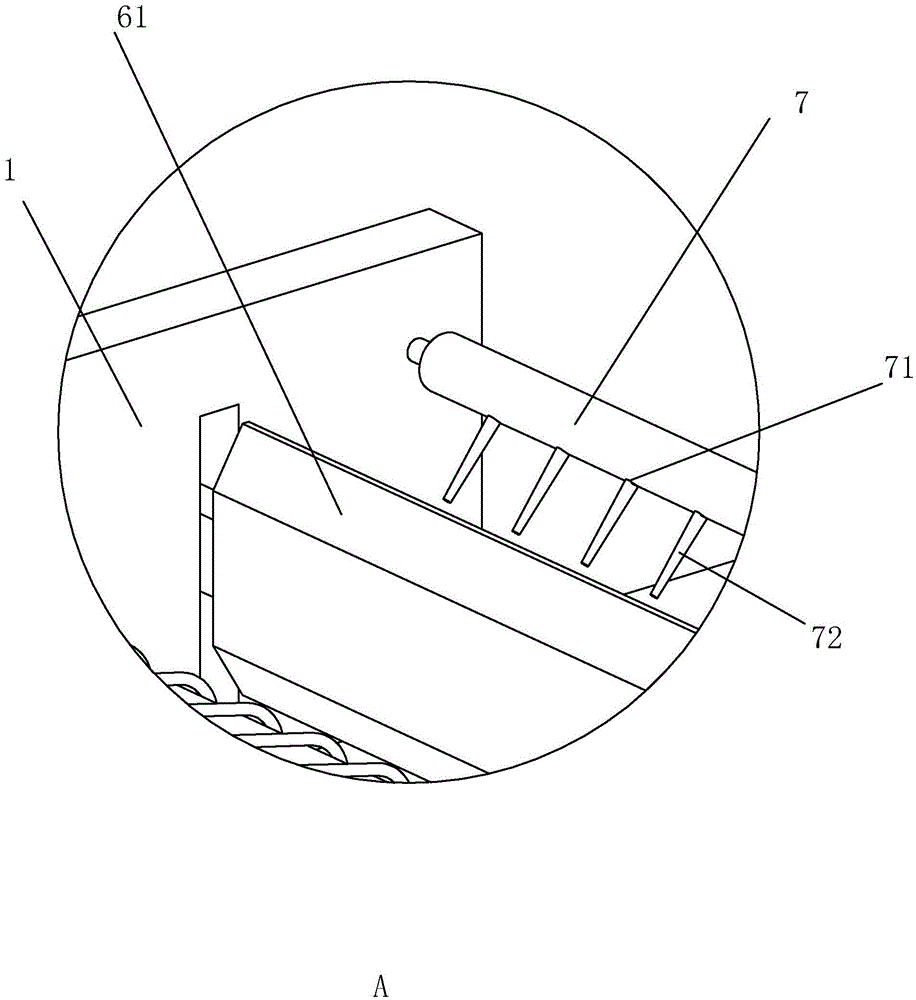

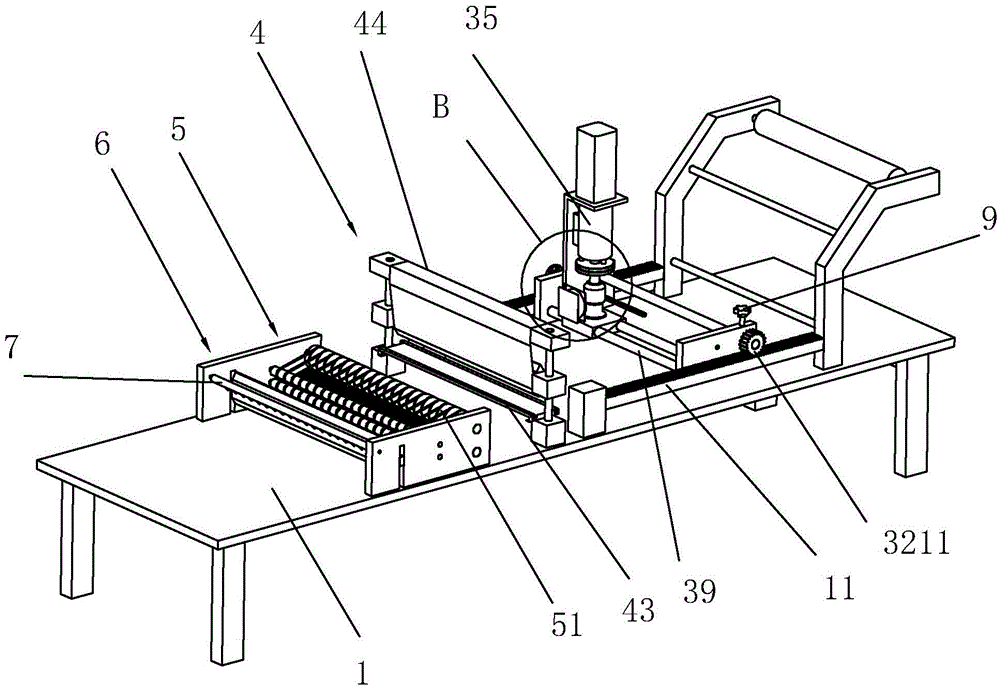

[0028] refer to Figure 1 to Figure 9 The embodiment of the bag making machine of the present invention will be further described.

[0029] A bag making machine, comprising a frame 1, on which a feeding device 2 for feeding plastic film rolls and a heat sealing device 4 are arranged, the feeding device 2 includes a feeding turntable 21, and the feeding turntable 21 rotates It is arranged on the frame 1, and a cylindrical plastic film roll is wound on the feeding turntable 21. During operation, the plastic film is pulled out from the feeding turntable 21 to realize the feeding of the bag making machine, wherein the plastic film roll In the last processing procedure, the self-sealing strip 82 has been bonded to the mouth of the bag along the length direction of the plastic film roll in advance, so it is only necessary to heat seal along the width direction of the plastic film roll, and then the plastic film is sealed. Cutting, can form plastic film bag, and heat-sealing device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com