Semi-automatic rotary turnover mechanism

A semi-automatic and flipping mechanism technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of low work efficiency, high labor intensity, and increased production costs for operators, and achieve simple structure, reduce labor intensity, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

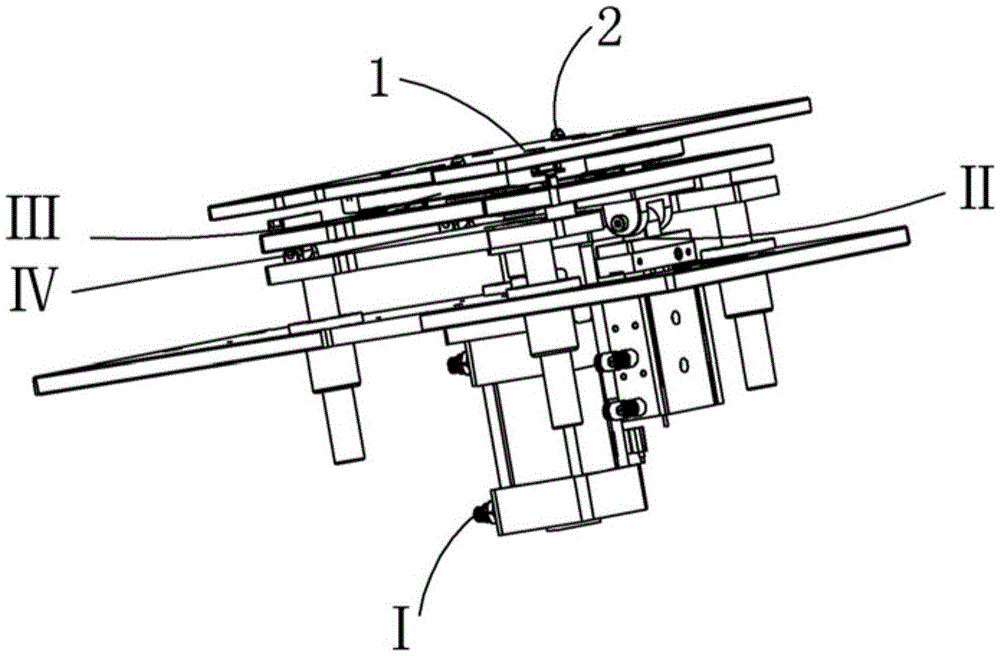

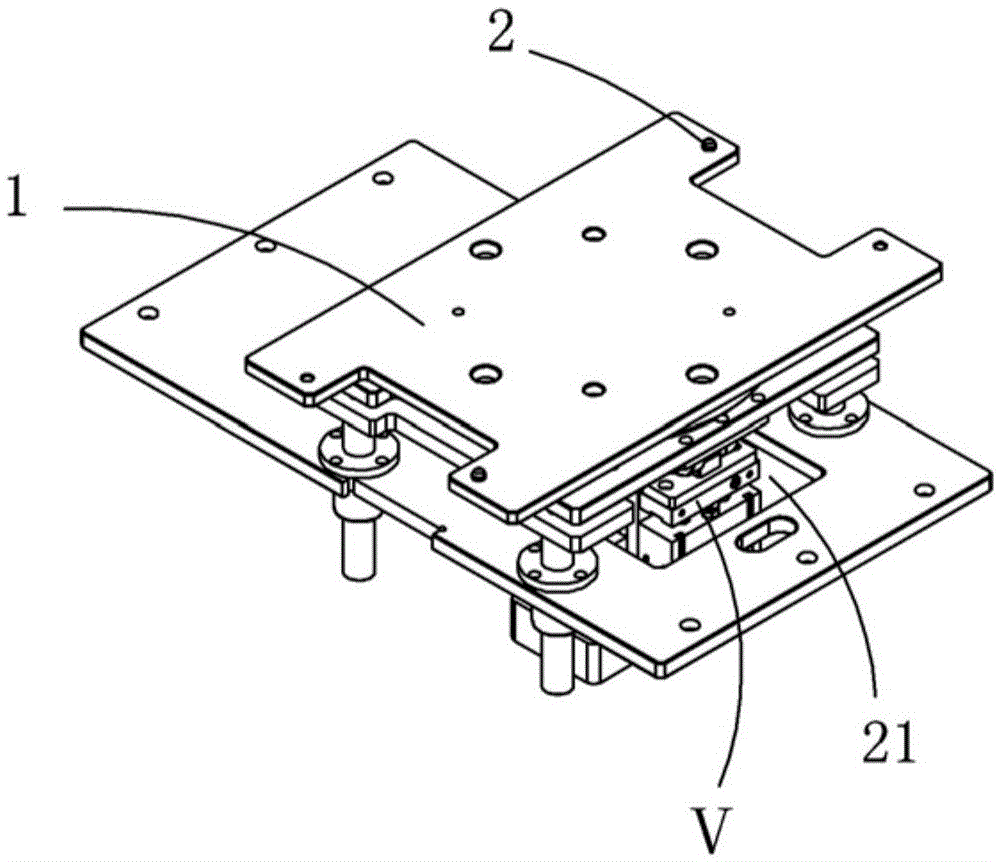

[0029] Examples, see attached Figure 1-8 , a semi-automatic rotating rollover mechanism, including a jacking assembly I, a side turning mechanism II is installed on the jacking assembly; a rotating assembly III is installed on the side turning mechanism, and a positioning plate 1 is installed on the rotating assembly , a tray is installed on the positioning plate, and the product is placed on the tray; the positioning pin 2 is arranged on the positioning plate, and a tray hole is provided on the tray, and the positioning pin cooperates with the tray hole to realize the positioning of the product.

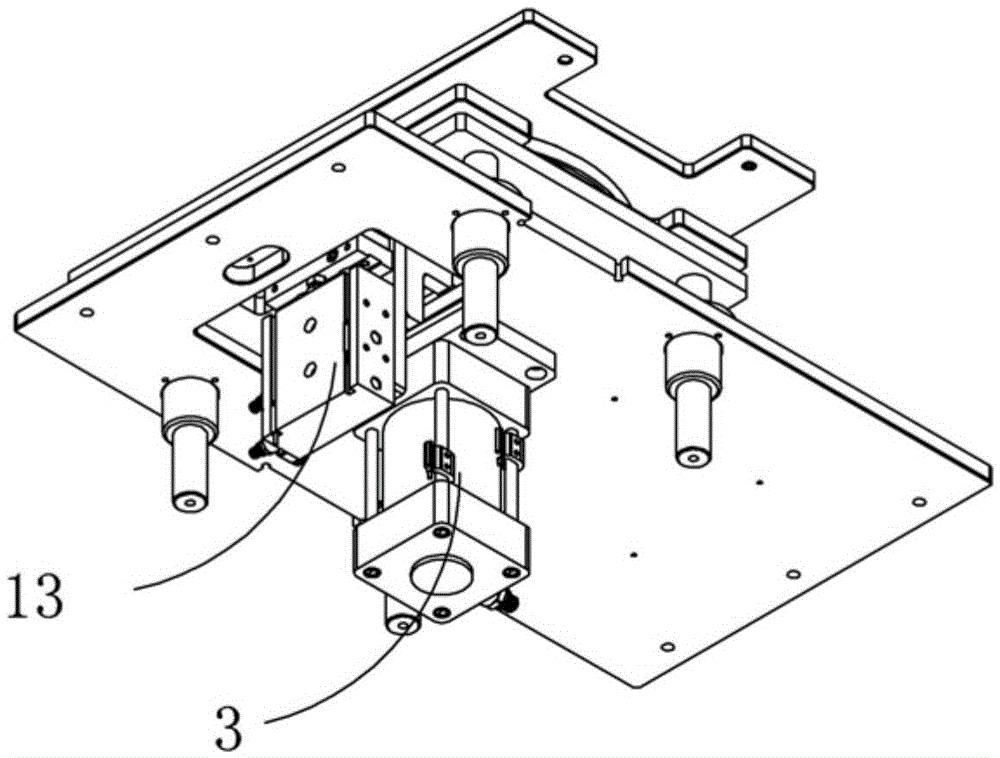

[0030] The jacking assembly includes a jacking cylinder 3, a jacking mounting plate 4, a jacking guide post 5 and a jacking guide sleeve 6, the jacking cylinder is installed under the jacking mounting plate, and four A set of jacking guide sleeves, there are four jacking guide pillars, which are respectively installed under the rollover support plate, and the four jacking guide pil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com