Water-borne acrylate pressure-sensitive adhesive, preparation method and pressure sensitive adhesive tape

A water-based acrylate and butyl acrylate technology, applied in the field of pressure-sensitive adhesives, can solve problems such as poor water resistance, improve cohesive strength and temperature resistance, reduce the risk of glue dropping, and be difficult to glue residue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

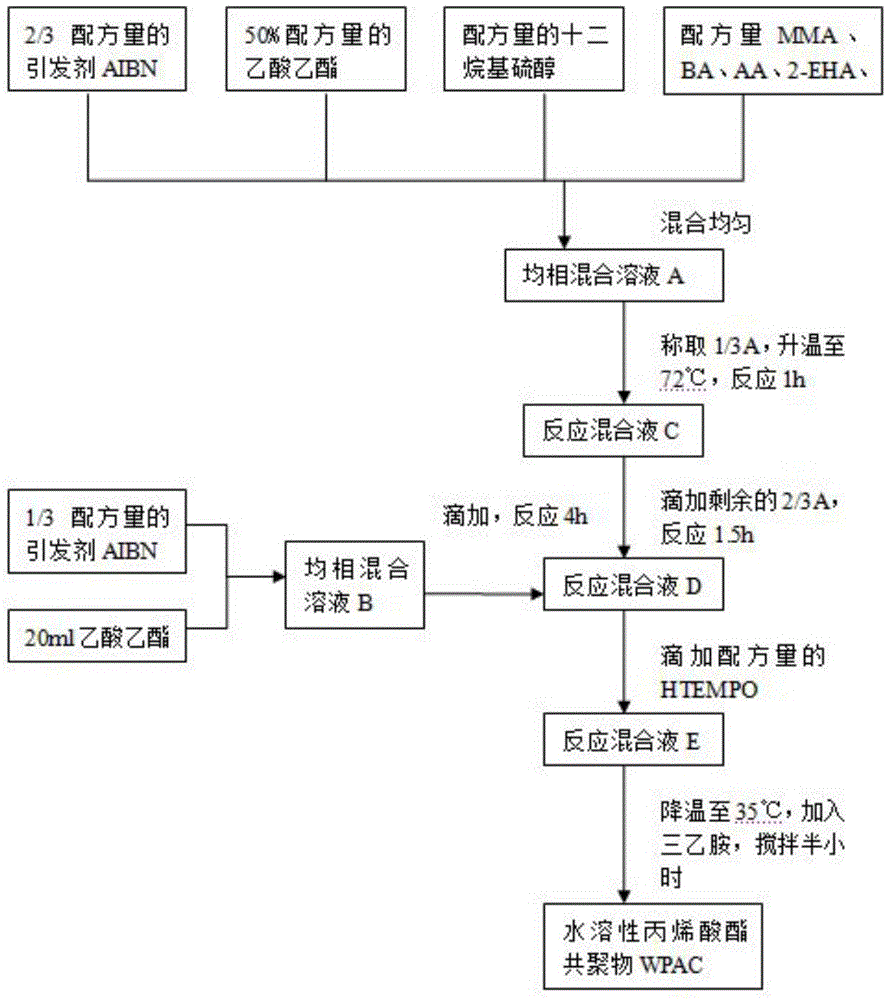

Method used

Image

Examples

Embodiment 1

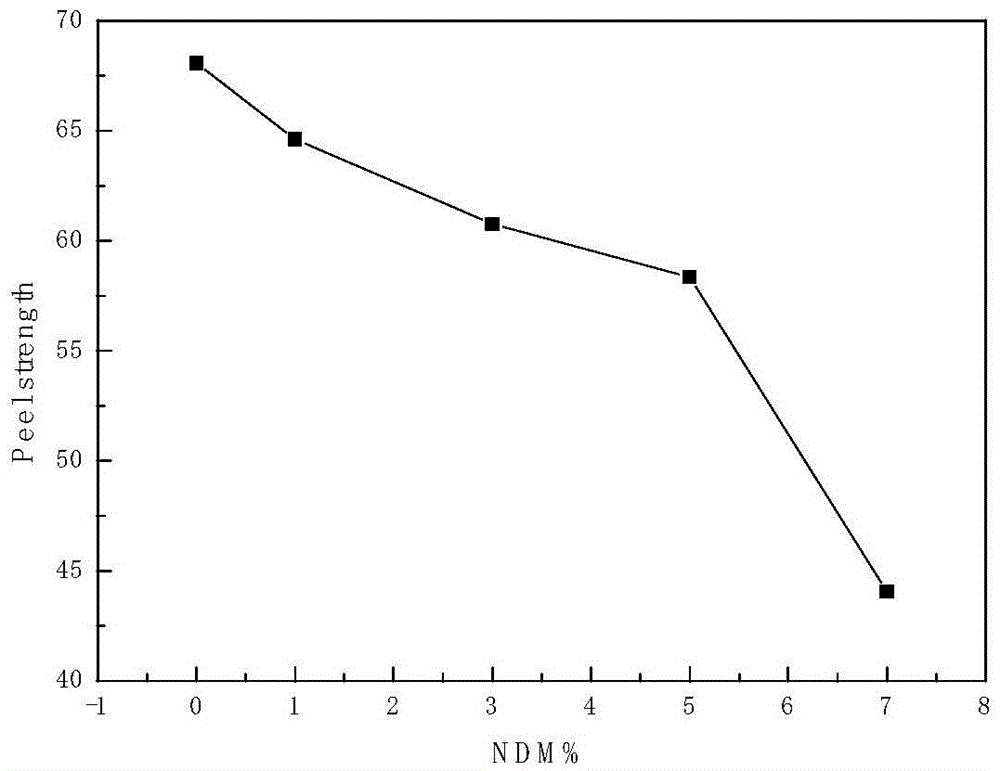

[0079] The synthetic formula of Example 1 is shown in Table 3 below.

[0080] The experimental formula of table 3 n-dodecylmercaptan (0%)

[0081] Reagent name

Embodiment 2

[0083] The synthetic formula of Example 2 is shown in Table 4 below.

[0084] The experimental formula of table 4 n-dodecylmercaptan (1%)

[0085] Reagent name

experiment approach 3

[0087] The synthetic formula of Experimental Scheme 3 is shown in Table 5 below.

[0088] The experimental formula of table 5 n-dodecylmercaptan (3%)

[0089] Reagent name

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap