A light hydrocarbon oil artificial continuous gas production device and method

A light hydrocarbon oil, oil and gas technology, applied in the field of light hydrocarbon oil artificial gas production equipment, to achieve the effect of low production cost, stable gas production, and no reflux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

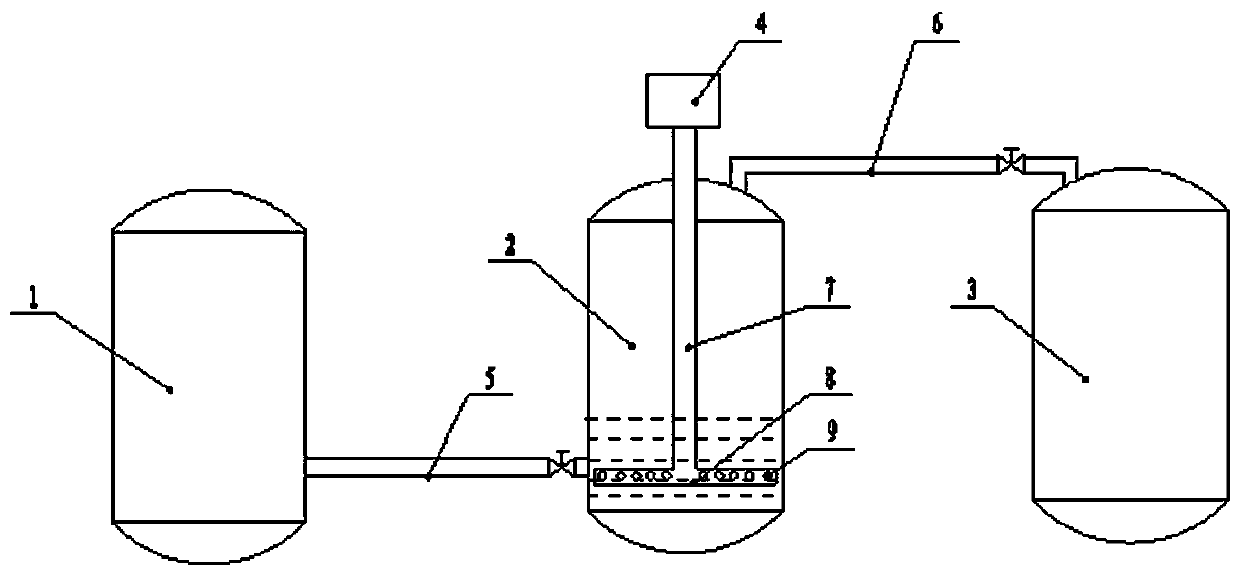

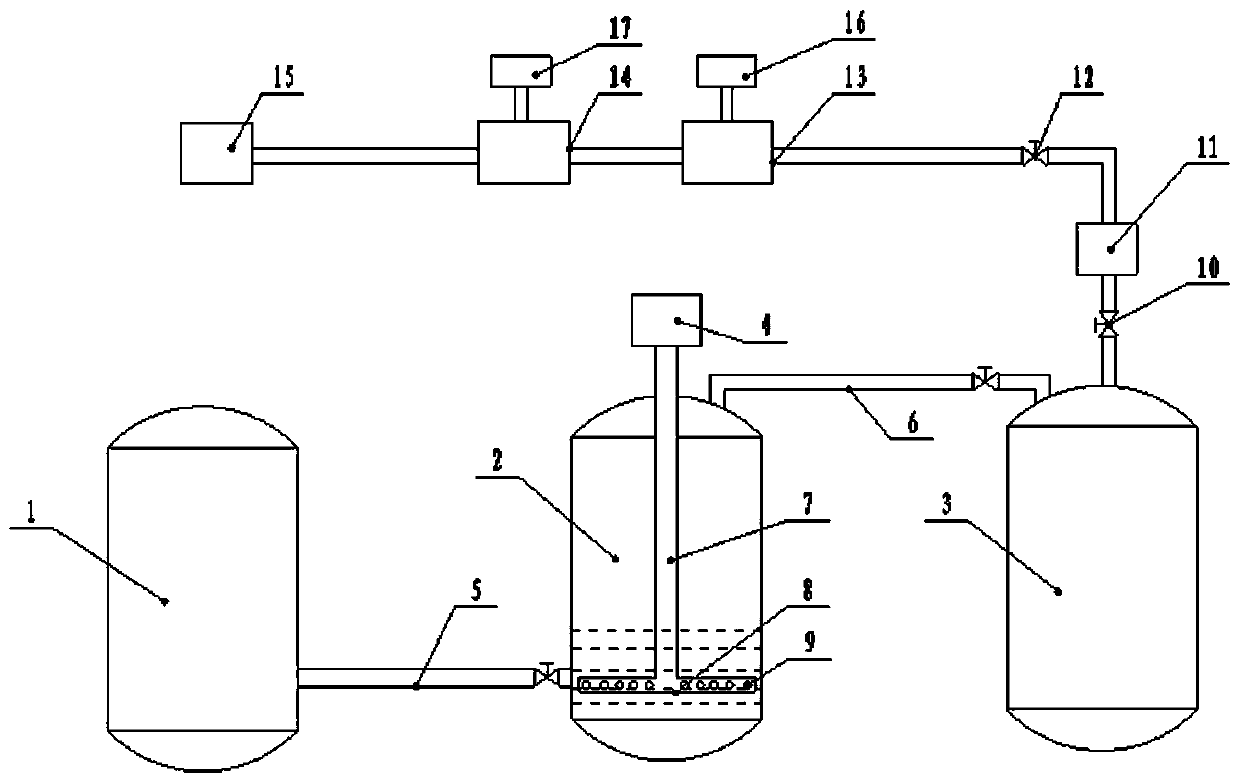

[0012] A light hydrocarbon oil artificial continuous gas production device, such as figure 1 As shown, it includes a crude oil tank 1, a gas tank 2, and a pressurized buffer tank 3, wherein an oil-gas mixer connected to an air compression pump 4 is arranged in the gas tank, and the bottom of the crude tank is connected to the system through a light hydrocarbon oil delivery pipe 5. The bottom of the gas tank is connected, and the top of the gas tank is connected to the pressurized buffer tank through the light hydrocarbon gas delivery pipe 6; the structure of the oil-gas mixer includes an air input pipe 7 connected to the air compressor pump, and the air input pipe is inserted into the bottom of the airtight gas tank , the end of the air inlet pipe is installed with a gas distribution pipe 8 perpendicular to it, and the gas distribution pipe is provided with ventilation holes 9 at intervals. The oil-gas mixer can be made of galvanized steel pipe, which is corrosion-resistant and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| autoignition temperature | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com