Reciprocated sliding mechanism of bracket of double-needle-bed warp knitting machine

A double-needle-bed warp knitting machine and reciprocating sliding technology, applied in the field of warp knitting machines, can solve problems such as complex structure, achieve the effects of reasonable mechanism design, increase motion stability and rigidity, and reduce wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

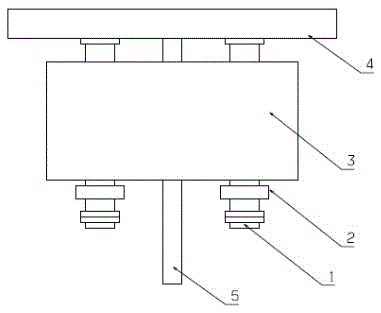

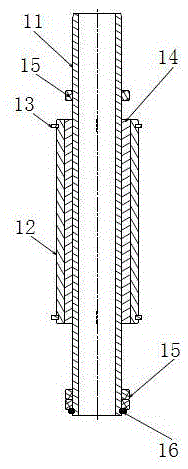

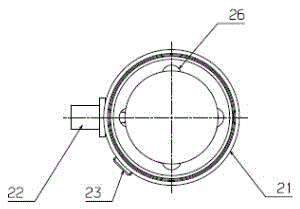

[0017] Such as Figure 1-4 It is a structural schematic diagram of the present invention, a double-needle bed warp knitting machine bracket reciprocating sliding mechanism, including two guide post assemblies 1, oiling sleeve assembly 2, needle bed guide seat 3, needle bed bracket 4 and a connecting rod 5. The guide column assembly 1 passes through the inner cylindrical hole of the needle bed guide seat 3 and is fixedly connected with the needle bed bracket 4. The connecting rod is installed in the middle of the needle bed bracket, and the two guide post assemblies 1 are located on both sides of the connecting rod 5. The oiling sleeve The assembly 2 is set on the guide post assembly 1, the guide post assembly 1 includes a guide post 11, the surface of the guide post 11 is covered with a ball frame 14, the ball frame 14 is covered with a guide sleeve 12, and the upper and lower ends of the guide sleeve 12 are provided with guide sleeve retaining rings 13. The upper and lower en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com