Basalt ultra-high-temperature split material and manufacturing process thereof

A production process, basalt fiber technology, applied in textiles, papermaking, non-woven fabrics, etc., can solve the problems of reduced toughness, limited heat insulation capacity, and inability to prepare thicker materials, so as to increase tensile capacity and stiffness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

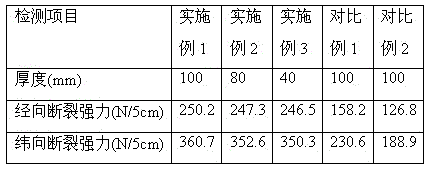

Examples

Embodiment 1

[0025] 1) Mixing: Stir the basalt fiber with a length of 17cm~23cm in the material box, mix well, and form a single-fibrous basalt fiber; the mixing time for mixing is 0.8h, and the rotation speed of the rocker arm is 40r / min;

[0026] 2) Flat curtain feeding: send the mixed material into single fiber basalt fiber to the opening machine by flat curtain conveyor;

[0027] 3) Fiber opening and web forming: the basalt fibers mixed into single fibers are opened and formed into a web by a fiber opener, and then fed into the needle loom by clamping two rollers after the fiber is formed into a web; Fiber web output, cylinder speed 45HZ; cylinder diameter 60mm.

[0028] 4) Acupuncture: The basalt fiber acupuncture thermal insulation material is made through upper acupuncture and lower acupuncture at the same time. The acupuncture process is carried out at the same time. times / min; needle density of acupuncture machine: 4000 pieces / m; output speed: 4m / min; stroke: 50mm; needle frequen...

Embodiment 2

[0031] 1) Mixing: Stir the basalt fiber with a length of 17cm~23cm in the material box, mix well, and form a single-fiber basalt fiber; the mixing time for mixing is 1h, and the rocker arm speed is 30r / min;

[0032] 2) Flat curtain feeding: send the mixed material into single fiber basalt fiber to the opening machine by flat curtain conveyor;

[0033] 3) Fiber opening and web forming: the basalt fibers mixed into single fibers are opened and formed into a web by a fiber opener, and then fed into the needle loom by clamping two rollers after the fiber is formed into a web; Fiber web output, cylinder speed 45HZ; cylinder diameter 60mm.

[0034] 4) Acupuncture: The basalt fiber acupuncture thermal insulation material is made through upper acupuncture and lower acupuncture at the same time. The acupuncture process is carried out at the same time. times / min; needle density of acupuncture machine: 4000 pieces / m; output speed: 6m / min; stroke: 50mm; needle frequency of upper acupunct...

Embodiment 3

[0037] 1) Mixing: Stir the basalt fiber with a length of 17cm~23cm in the material box, mix well, and form a single-fibrous basalt fiber; the mixing time for mixing is 0.5h, and the rotation speed of the rocker arm is 50r / min;

[0038] 2) Flat curtain feeding: send the mixed material into single fiber basalt fiber to the opening machine by flat curtain conveyor;

[0039] 3) Fiber opening and web forming: the basalt fibers mixed into single fibers are opened and formed into a web by a fiber opener, and then fed into the needle loom by clamping two rollers after the fiber is formed into a web; Fiber web output, cylinder speed 40HZ; cylinder diameter 60mm.

[0040]4) Acupuncture: The basalt fiber acupuncture thermal insulation material is made through upper acupuncture and lower acupuncture at the same time. The acupuncture process is carried out at the same time. times / min; needle density of acupuncture machine: 4000 pieces / m; output speed: 0.6m / min; stroke: 50mm; needle freque...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com