Integrated filling prefabricated slab damping track structure

A prefabricated plate, integrated technology, applied in the field of track structure, can solve the problems of small curve radius, narrow construction work surface, low construction accuracy, etc., to reduce the transmission of stray current, reduce the difficulty of replacement, and protect the stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

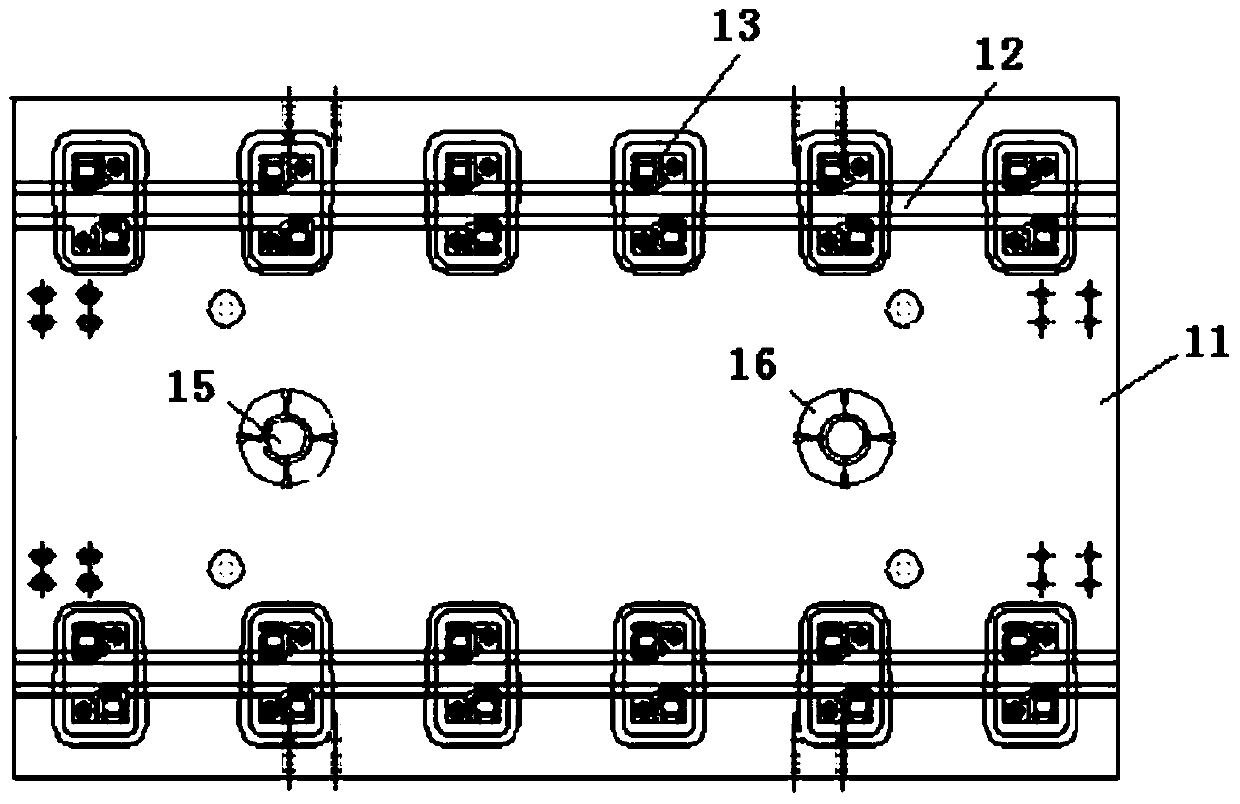

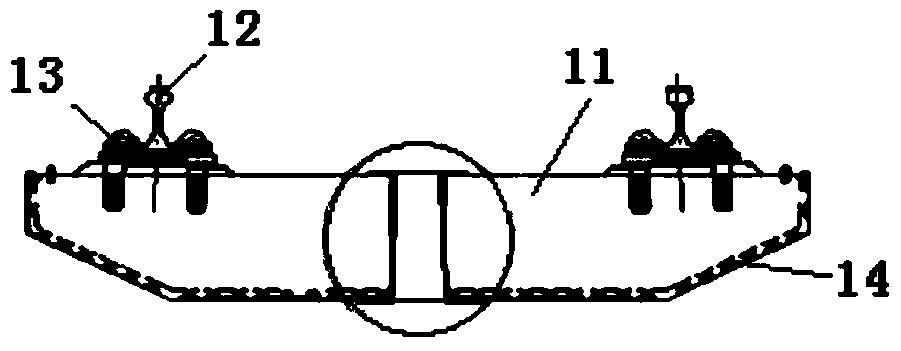

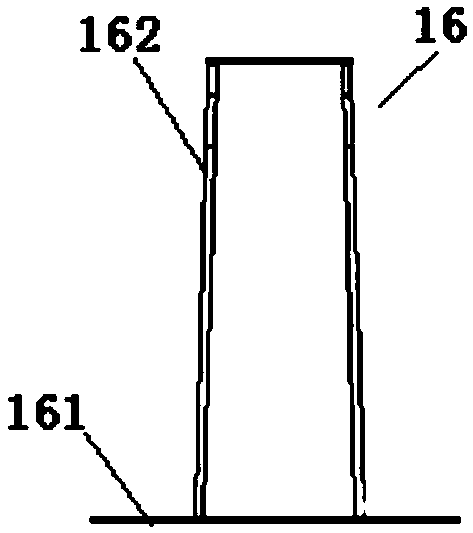

[0030] see figure 1 , shows the integrated filling type prefabricated slab damping track structure of the present invention.

[0031] The integrated filling type prefabricated slab damping track structure includes a prefabricated slab body 11 , and the upper surface of the prefabricated slab body 11 is provided with rails 12 and fasteners 13 for fixing the rails 12 .

[0032] Wherein, the section of the prefabricated slab body is a symmetrical or asymmetrical polygonal shape to adapt to different tunnel section forms at the bottom, and the two sides of the bottom of the track slab adopt a slope structure in the form of chamfered corners; The groove is convenient for the effective connection and sealing between the damping cushion and the prefabricated slab; the upper surface of the track slab is a horizontal plane or a slope surface of a certain form; The slab body adopts a non-prestressed reinforced concrete structure, and the prefabricated slab body is provided with at leas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com