Dam breaking opening pile jetting machine and pile jetting method thereof

A technology of breaching and pile driving, which is applied in the direction of sheet pile wall, building, foundation structure engineering, etc., can solve the problems of low work efficiency, loss, time-consuming, etc., and achieve the effect of fast and effective piling, simple operation and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

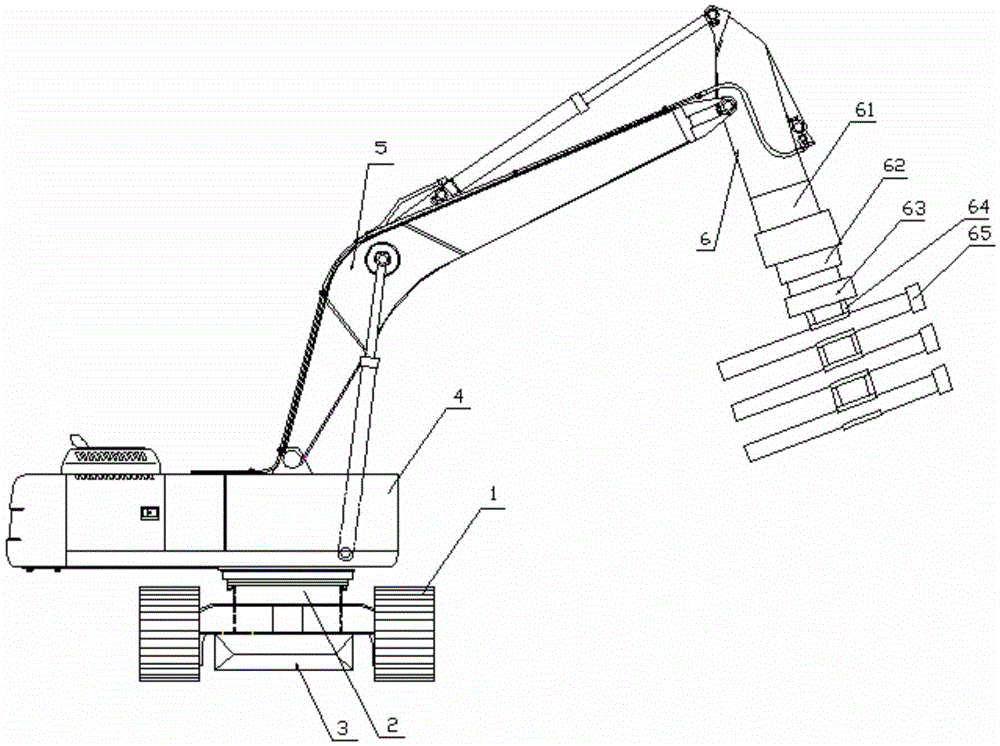

[0036] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , the present invention is: a dam breach pile driver, comprising two oppositely arranged driving wheels 1, a driving axle housing 2 arranged between the two driving wheels 1, a pile bucket 3 and an operating platform arranged on the driving axle housing 2 4, and the cantilever 5 arranged on the operation platform 4, wherein, one end of the cantilever 5 is arranged on the turntable seat controlled by the main engine of the operation platform 4, and the other end is hinged with a power arm 6, and the end of the power arm 6 is provided with a launch mechanism;

[0037] The power arm 6 includes a telescopic arm 62, a hydraulic cylinder 61 arranged at one end of the telescopic arm 62, and a piston rod of the hydraulic cylinder 61 is connected with the telescopic arm 62;

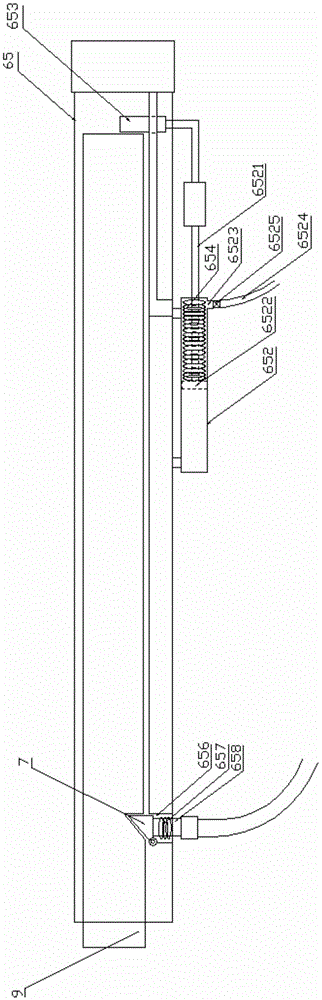

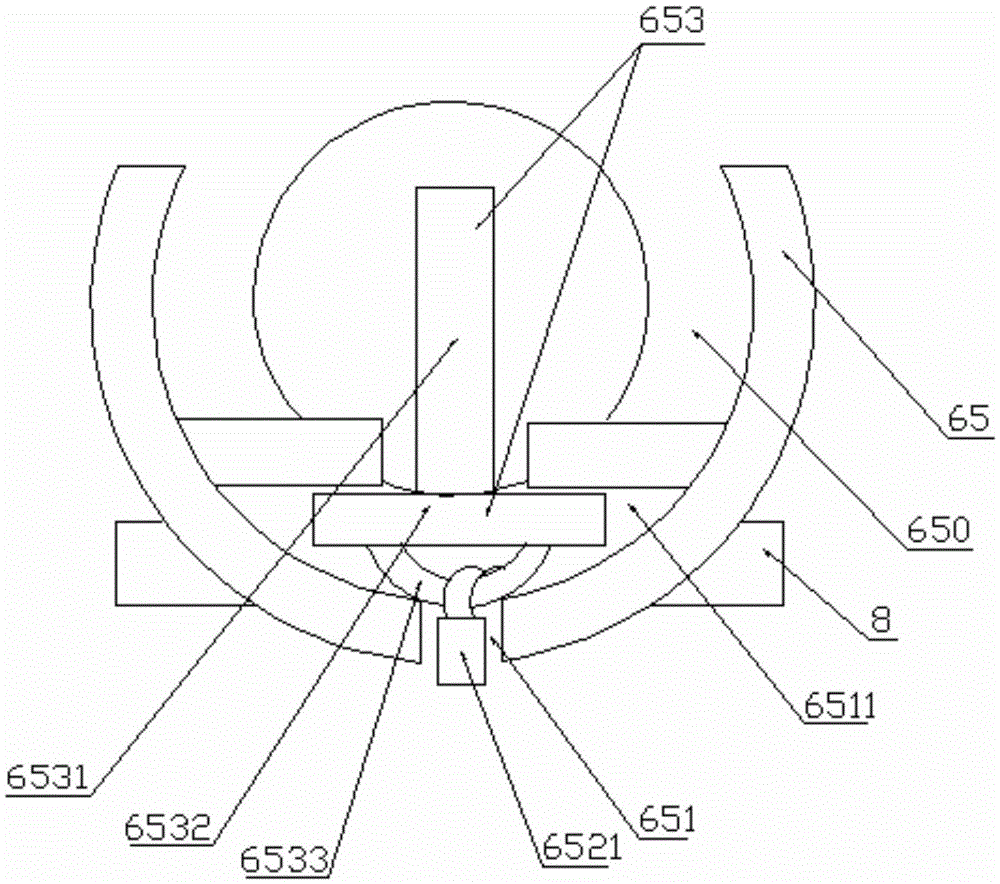

[0038]Launching mechanism comprises the rotating disk 63 that is arranged on telescopic arm 62 other ends, is arranged on the launching seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com