Rebar prying hook

A technology of steel bars and hooks, applied in the field of construction auxiliary construction tools, can solve problems such as affecting work efficiency, and achieve the effects of improving work efficiency, improving construction quality and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

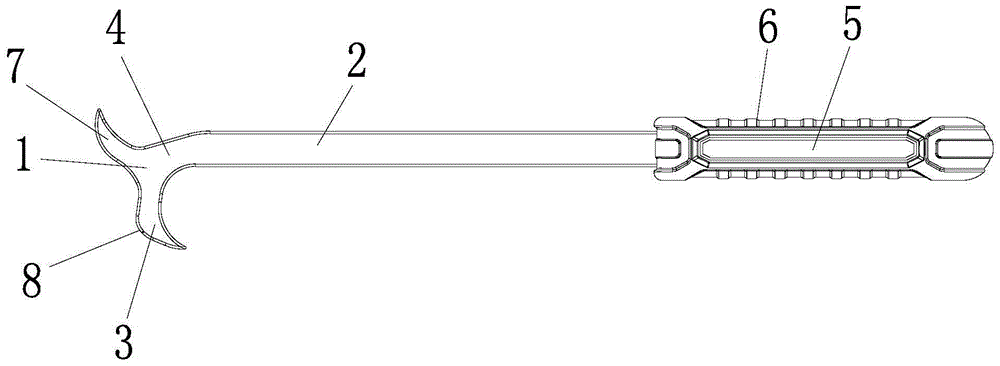

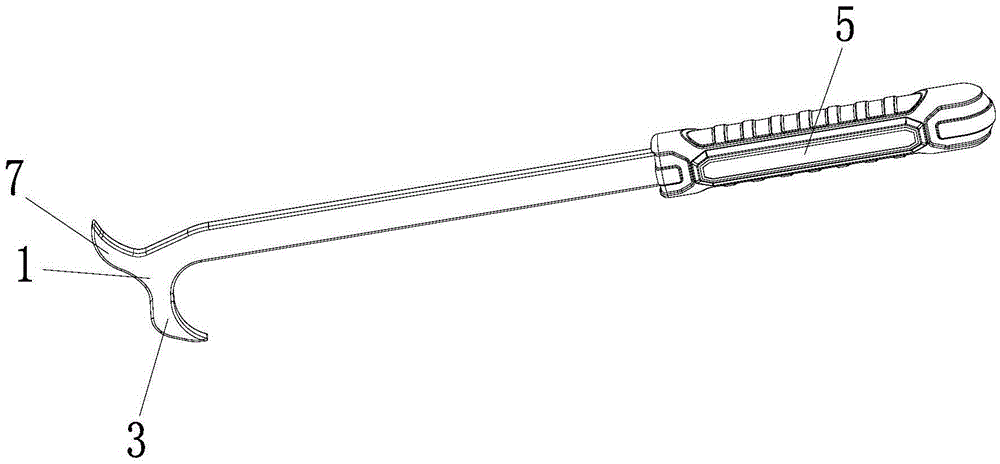

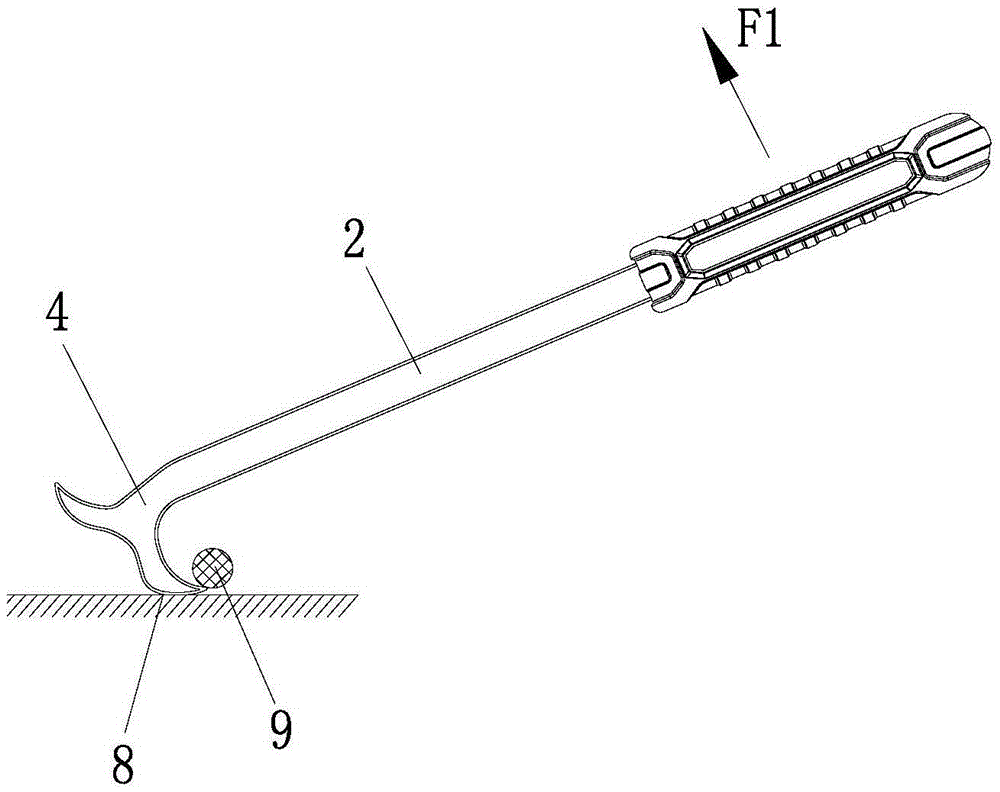

[0023] A steel bar prying hook, comprising a hook body 1 and a hook bar 2, the hook body is arranged at one end of the hook bar.

[0024] Preferably, the hook body has two hooks, and the two hooks are arranged on the hook rod to form an "r"-shaped structure.

[0025] Preferably, the hook body includes two crotches and a crotch connecting rod 4, the two crotches are respectively arranged on opposite sides of the crotch connecting rod and the two crotches protrude outwards in opposite directions, the The crotch connecting rod is connected with the hook rod.

[0026] In order to pry up the steel bars more conveniently, preferably, the hook connecting rod protrudes obliquely toward one of the hooks, and an included angle of 150°-175° is formed between the hook connecting rod and the hook rod.

[0027] Preferably, one of the two crotches is a support pry hook 3 capable of supporting and prying up the steel bar 9, and the other is a pry hook 7, and the support part 8 is provided on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com