Pipeline connection structure

A technology for connecting structures and pipes, which is applied to mechanical equipment, couplings, etc., can solve the problems of narrow installation position, unchanged installation and disassembly, time-consuming and labor-intensive problems, and achieves the effect of convenient installation and disassembly and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

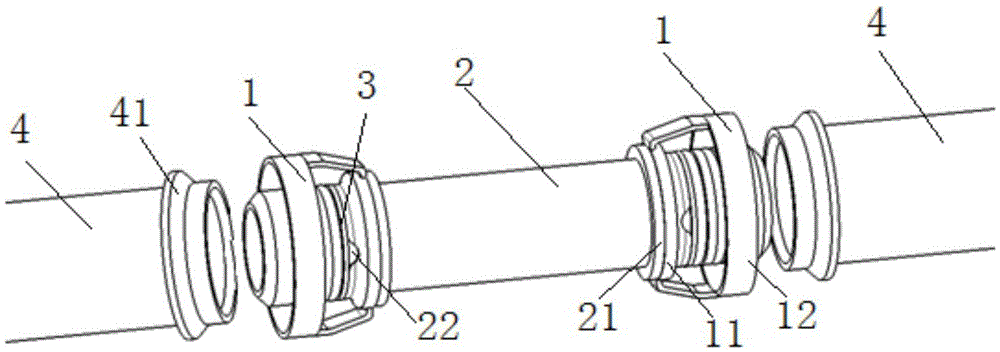

[0022] Referring to the accompanying drawings, a pipeline connection structure includes two mother pipes 4 that need to be docked, and the two mother pipes 4 are connected by connecting pieces;

[0023] The connecting piece includes a connecting pipe 2 and a pipe joint 1 sleeved at both ends of the connecting pipe 2, the two ends of the connecting pipe 2 are respectively inserted in two female pipes 4, and the two ends of the connecting pipe 2 are in A sealing ring 3 is provided at the connection with the main pipe 4;

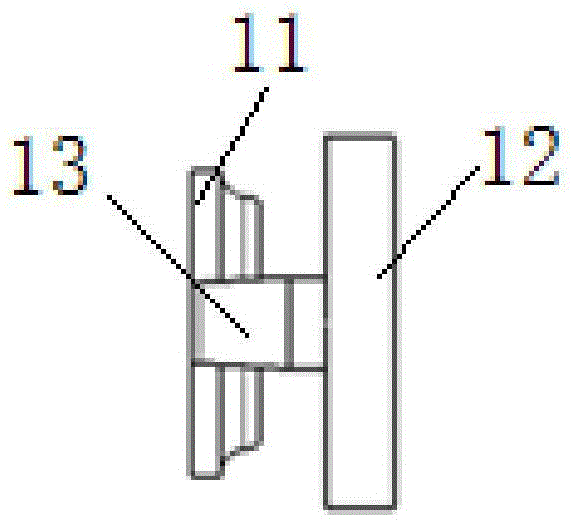

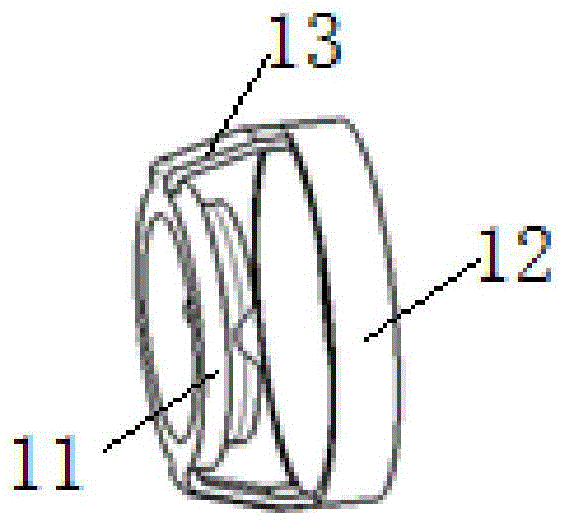

[0024] The pipe joint 1 includes an elastic small ferrule 11 and a large ferrule 12, the small ferrule 11 is in the shape of a ring, the large ferrule 12 is in the shape of an oval ring, the small ferrule 11 and the large ferrule 12 is arranged coaxially, and the two sides of the small ferrule 12 are respectively connected to the two ends of the long axis of the large ferrule 12 through the elastic piece 13;

[0025] The small ferrule 11 is sleeved on the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com