Incremental hot air circulation cocoon drying mechanism and method thereof

A hot air circulation, incremental technology, applied in dryers, progressive dryers, drying and other directions, can solve the problems of uneven drying, poor cocoon production quality, inability to achieve rapid temperature rise and energy saving, etc. The effect of improving the quality of silkworm cocoons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

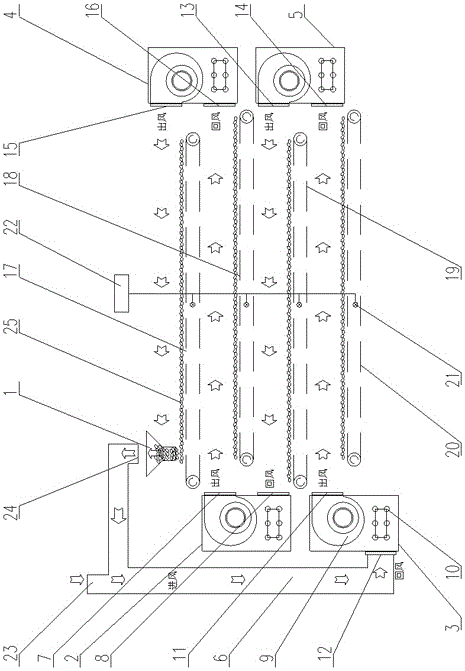

[0018] Embodiment: a kind of incremental hot air circulation cocoon drying mechanism of this example, such as figure 1 , including a cocoon conveyor belt, the cocoon conveyor belt is multi-layered, a cocoon bucket 1 is arranged above the cocoon conveyor belt on the uppermost layer, and a first heater 2 and a second heater 3 are arranged on one end of the cocoon conveyor belt from top to bottom , the other end of the cocoon conveyor belt is arranged with a fourth heater 4 and a third heater 5 from top to bottom, and the air outlets of the first heater and the second heater are respectively aligned with the fourth heater and the third heater The air return port of the first heater is aimed at the air outlet of the third heater, the air outlet of the fourth heater is aimed at the cocoon hopper, and the cocoon hopper is connected with the return air outlet of the second heater through the circulating air duct 6 above the cocoon hopper. The circulating air duct is connected with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com