Portable device for external field load calibration/strength test of aircraft two-force rod

A strength test, portable device technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of large size, high price, unable to truly reflect the tensile and compressive strain of the two-force rod, and achieve the correct test load, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the accompanying drawings and examples.

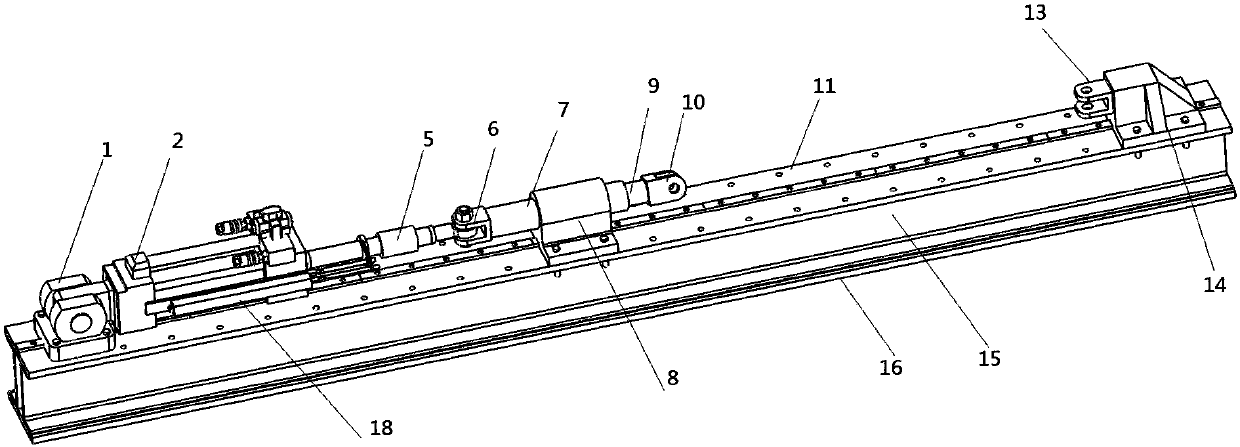

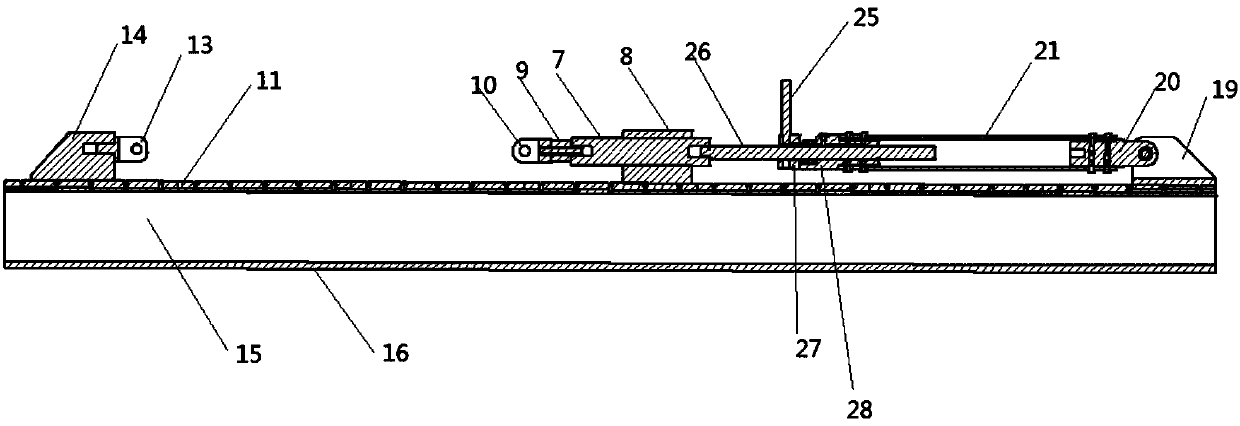

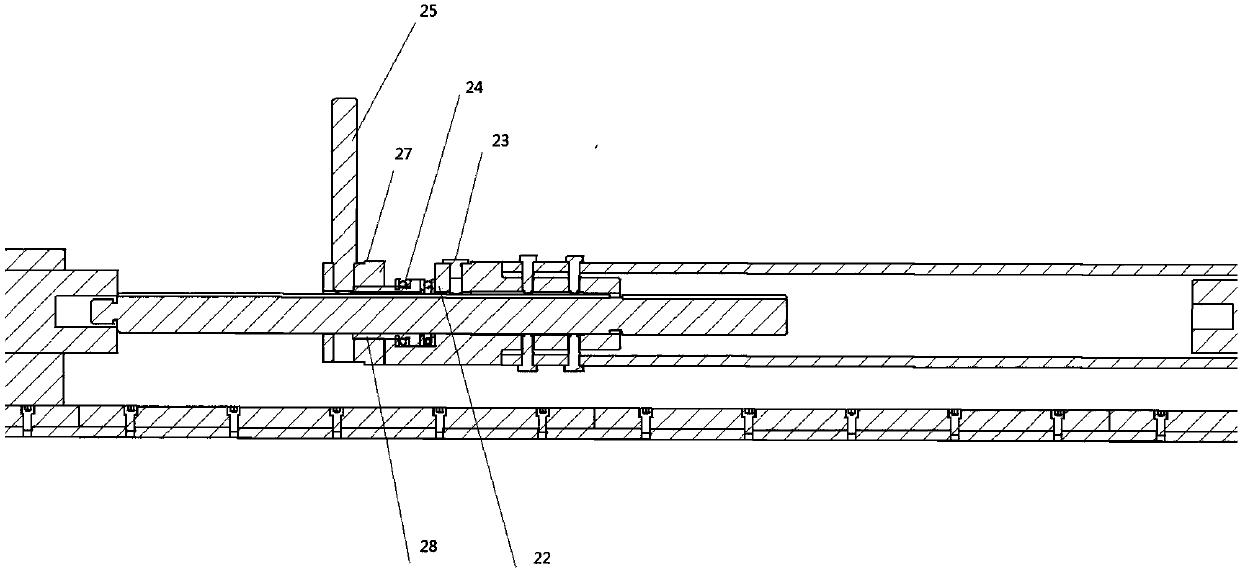

[0018] A portable device for external field load calibration / strength test of aircraft two-force bar, which includes: a load loading device, an orientation shaft 7, a tension and pressure sensor 9 for testing, a test piece base 14 and a support frame;

[0019] The support frame includes: a strip-shaped support 15 and a working platform 11 installed on the surface of the support 15; the center of the working platform 11 is provided with an axial positioning key;

[0020] The load loading device is installed on one end of the working platform 11, and the test piece base 14 fixedly installed with the lug joint C13 is installed on the other end of the working platform 11; the load loading device is connected with the orientation shaft 7; the other end of the orientation shaft 7 is connected with a The tension and pressure sensor 9 for the test of the double ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com