Food thawing pool

A food and box technology, applied in food preservation, food science, application, etc., can solve the problems of unsuitable large-scale production mode and slow process, and achieve the effect of simple structure, constant quality and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

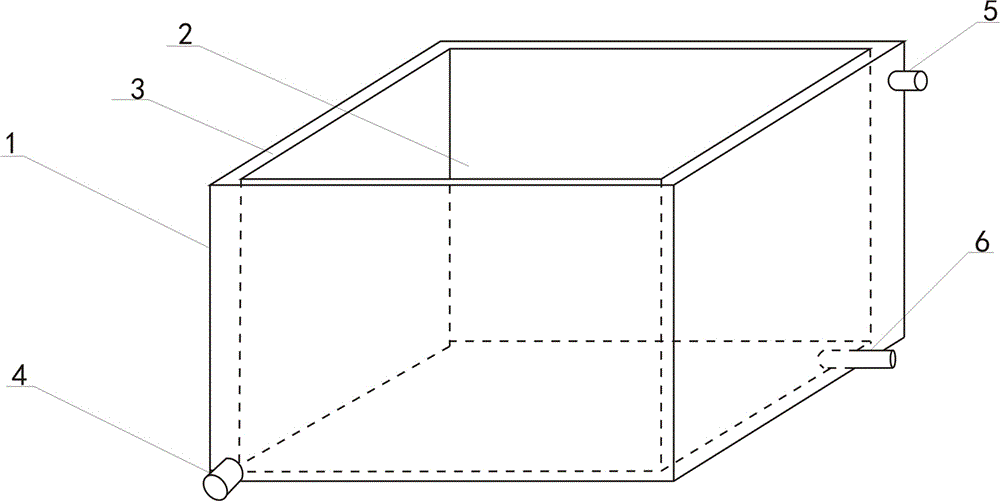

[0007] The technical features of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0008] The present invention consists of a square metal box (1), water outlet (4), water inlet (5) and water outlet (6). The box (1) is composed of a small box inside a large box. The inner cavity of the box (3) forms an interlayer between the small box and the big box, that is, there is a gap between the box wall and the bottom of the box, and the water outlet (4) and the drain ( 6), the water outlet (4) is only connected to the interlayer, the water outlet (6) passes through the box wall (3) and connects to the box inner cavity (2) and is sealed and fixed with the two-layer box wall, and the water inlet (5) is sealed and fixed At a certain upper corner of the box body (1), and only communicate with the box wall interlayer.

[0009] Example, when in use, you only need to place the frozen food in the inner cavity (2) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com