A fungus black garlic sauce

A technology of agaric fungus and black garlic sauce, applied in the field of food processing, can solve the problems of single taste, not strong enough sauce taste, unable to meet the requirements of nutritional flavor, etc., and achieve the effect of rich and mellow flavor and improving nutritional value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

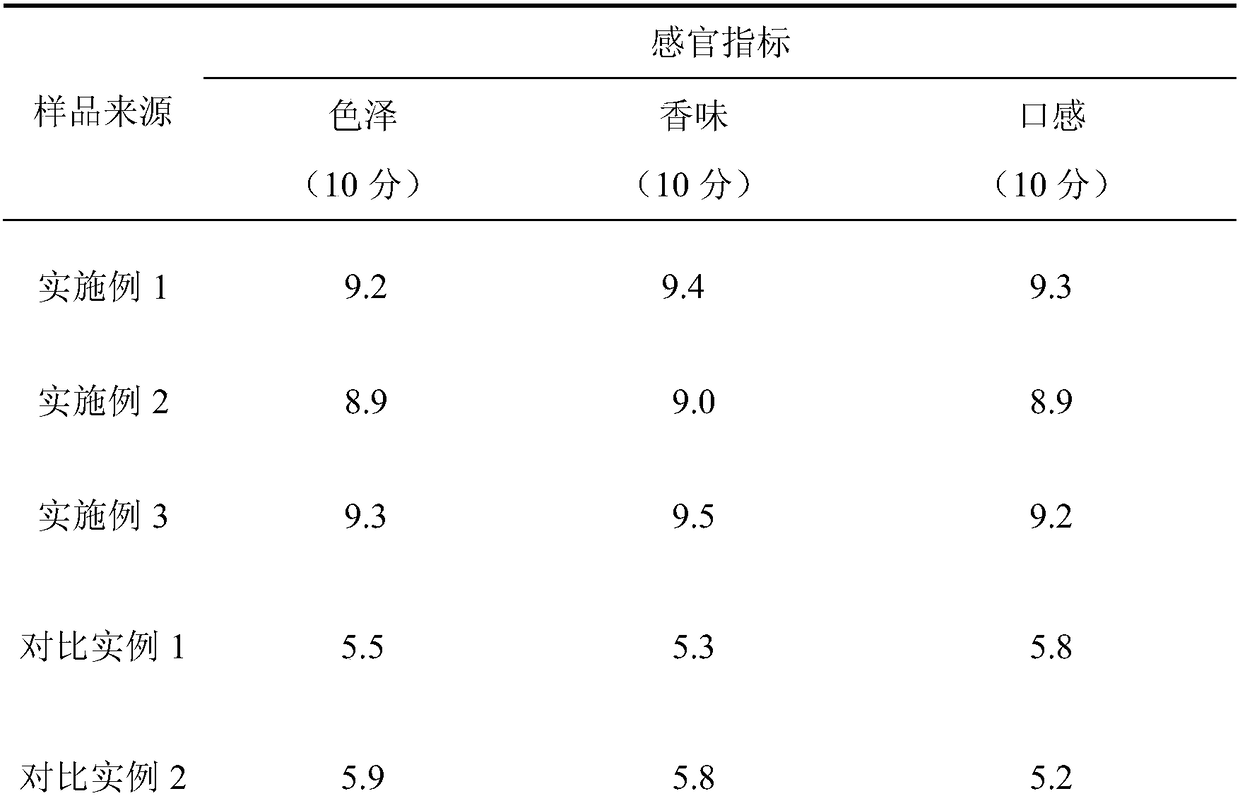

Embodiment 1

[0027] 1) Take 50KG garlic with skin and put it into an incubator, ferment at 60°C for 18 days to obtain black garlic;

[0028] 2) Peel the black garlic, wash it, add 8 times of water, and grind it into a black garlic slurry with a colloid mill;

[0029] 3) After pasteurizing the black garlic slurry obtained in step 2) at 90°C, inoculate the activated fungus solution with 5% of the volume of the black garlic slurry into the black garlic slurry, add 0.3% potassium dihydrogen phosphate, Cultivate in the fermenter for 12 days;

[0030] Culture conditions in fermenter: 25-27°C, 160r / min;

[0031] 4) After the fungus mycelium grows in the black garlic slurry in step 3), add 4% salt of the black garlic slurry that grows the black garlic mycelia, inoculate lactic acid bacteria and yeast with a volume of 2‰ of the black garlic slurry, and inoculate at 30 Aerobic fermentation of mixed bacteria at ℃ for 8 hours, and anaerobic fermentation at 25℃ for 20 days;

[0032] The volume ratio...

Embodiment 2

[0037] Embodiment 2, with embodiment 1, the difference is,

[0038] 1) Take 50KG garlic with skin and put it into an incubator, and ferment at 65°C for 15 days to obtain black garlic;

[0039] 2) Peel the black garlic, wash it, add 5 times of water, and grind it into a black garlic slurry with a colloid mill;

[0040] 3) After pasteurizing the black garlic slurry obtained in step 2) at 90° C., inoculate the activated fungus liquid with 10% of the black garlic slurry volume into the black garlic slurry, add 0.2% potassium dihydrogen phosphate, and Cultivate in the fermenter for 12 days;

[0041] 4) After the fungus mycelium grows in the black garlic slurry in step 3), add 8% salt of the black garlic slurry that grows the black garlic mycelium, inoculate lactic acid bacteria and yeast with a volume of 5‰ of the black garlic slurry, and incubate at 33°C Aerobic fermentation with mixed bacteria for 12 hours and anaerobic fermentation at 20°C for 15 days;

[0042] The volume rat...

Embodiment 3

[0048] Embodiment 3, with embodiment 1, the difference is,

[0049] 1) Take 50KG garlic with skin and put it into an incubator, ferment at 63°C for 13 days to obtain black garlic;

[0050] 2) Peel the black garlic, wash it, add 5 times of water, and grind it into a black garlic slurry with a colloid mill;

[0051] 3) After the black garlic slurry obtained in step 2) is pasteurized at 90° C., the activated fungus liquid with a volume of 8% of the black garlic slurry is inoculated into the black garlic slurry, and 0.2% potassium dihydrogen phosphate is added. Cultivate in the fermenter for 10 days;

[0052] 4) After the fungus mycelium grows in the black garlic slurry in step 3), add 6% salt of the black garlic slurry that grows the black garlic mycelium, inoculate lactic acid bacteria and yeast with a volume of 3‰ of the black garlic slurry, and incubate at 33°C Aerobic fermentation with mixed bacteria for 12 hours and anaerobic fermentation at 20°C for 15 days;

[0053] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com