An electrical control system for a laminated multi-head multi-combination grinding and polishing machine

An electric control system, grinding and polishing machine technology, applied in the direction of grinding automatic control device, grinding machine tool parts, grinding/polishing equipment, etc., can solve problems such as unsatisfactory processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

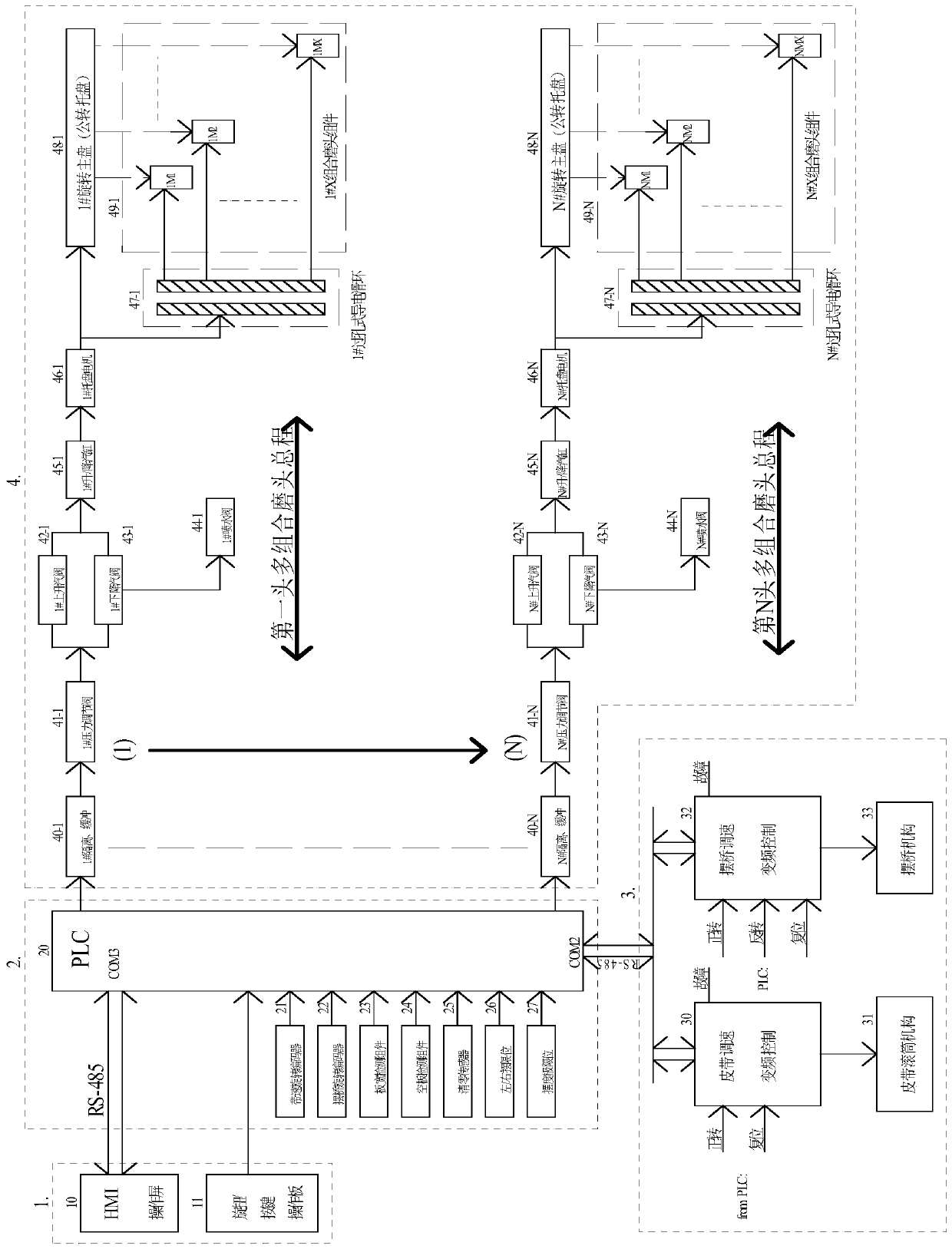

[0016] The following is attached figure 1 , figure 2 The present invention is described in detail, and this embodiment can make it easier for those skilled in the art to understand the present invention, but this embodiment does not limit the present invention.

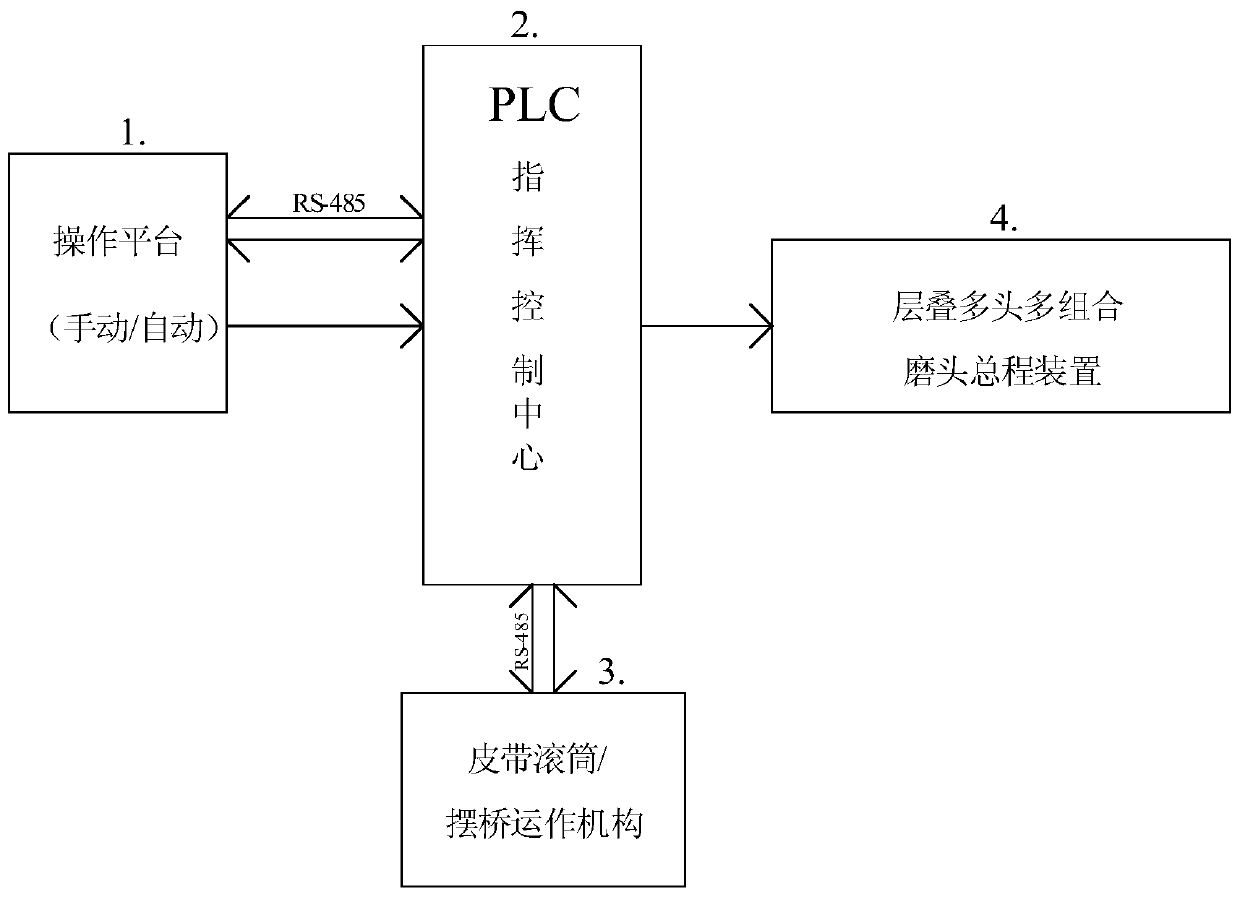

[0017] Such as figure 1 , 2 As shown, the present invention is an electrical control system for a stacked multi-head multi-combination grinding and polishing machine, which mainly includes: an operating platform 1, a PLC command and control center 2, a belt drum / swing bridge operating device 3, and a stacked multi-head multi-combination grinding head assembly device 4.

[0018] 1. Operation platform: refers to the work surface that provides the operation of the machine. It consists of touch screen HMI10, knob / button operation panel 11 (generally, as many grinding heads as there are nearby operation panels, it can be used as manual / automatic and single-head grinding. The HMI mainly issues various operating instruc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com