Automatic control device of disk saw for stone cutting and control method of automatic control device

An automatic control device and stone cutting technology, applied in stone processing tools, stone processing equipment, manufacturing tools, etc., can solve the problems of high noise in the working environment, high scrap rate, low efficiency, etc., to improve processing efficiency, reduce failures, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

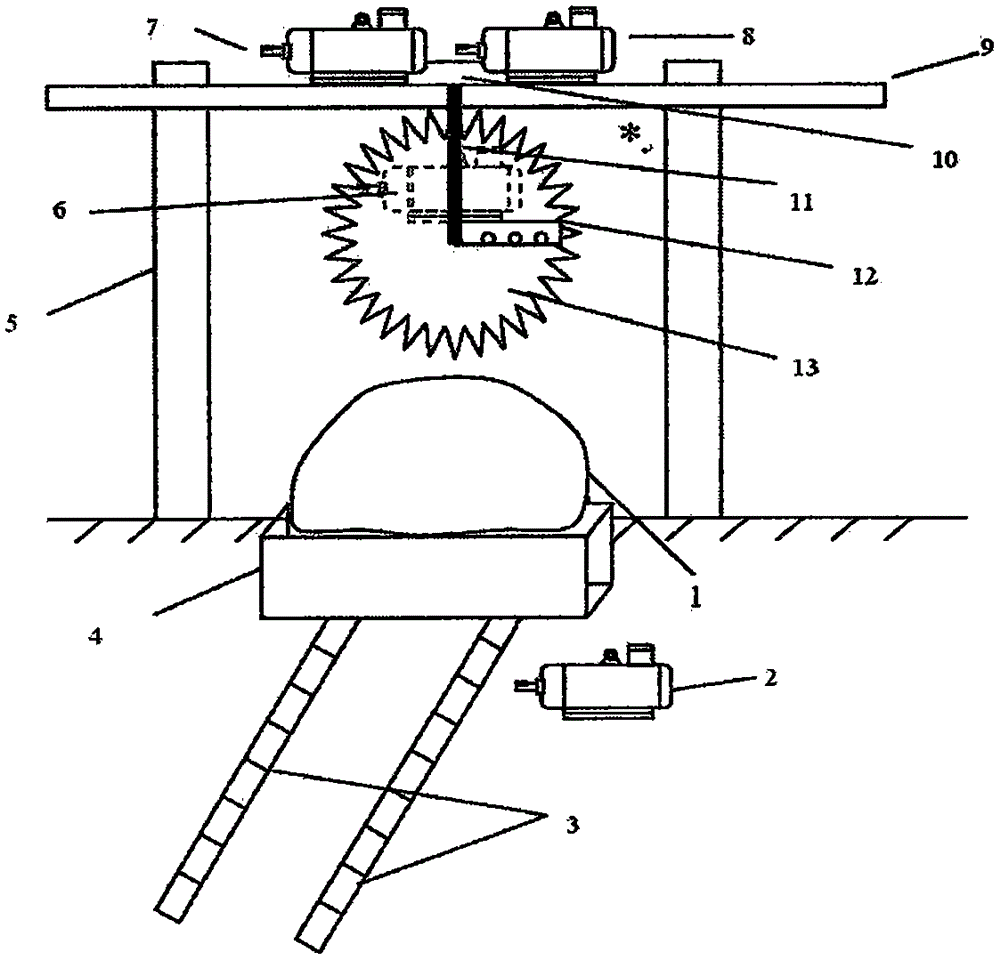

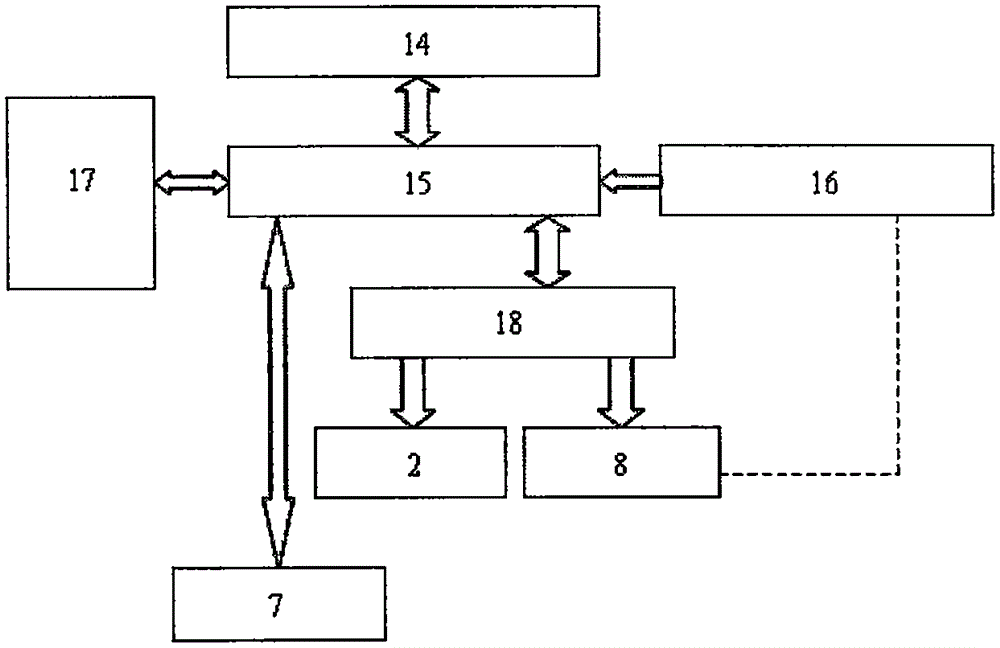

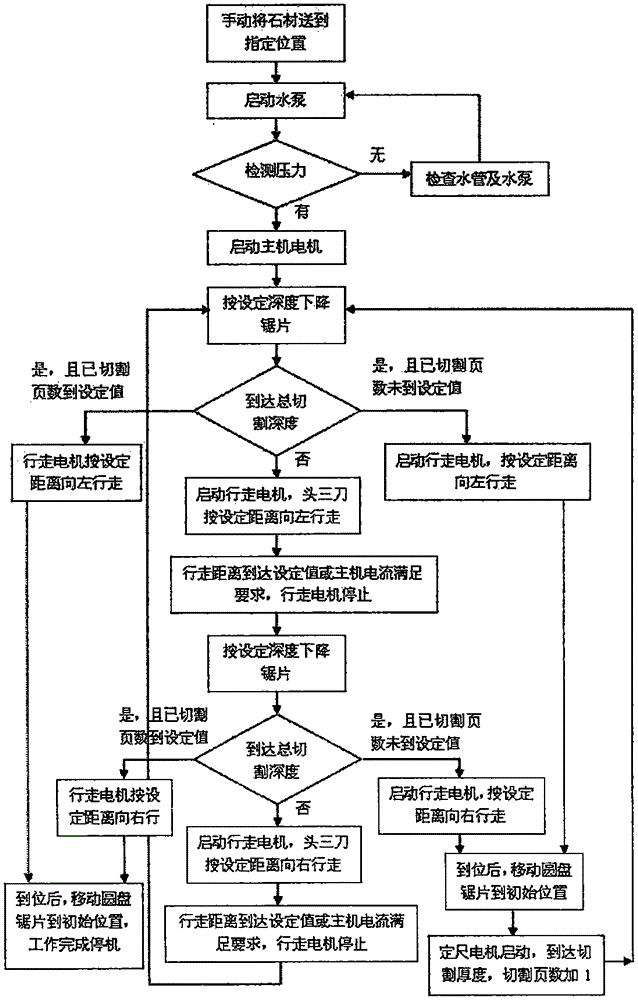

[0036] Such as figure 1 As shown, an automatic control device for a circular saw for stone cutting includes a length-setting motor 2, a rail 3, a cart 4, a plurality of pillars 5, a host motor 6, a lifting motor 7, a traveling motor 8, and a beam 9, The horizontal shaft 10, the main shaft 11, and the circular saw blade 13 are characterized in that the plurality of pillars 5 and the beam 9 form a frame, the circular saw blade 13 is rotatably fixed on the lower end of the main shaft 11, and the upper end of the main shaft 11 can slide laterally The ground is connected on the crossbeam 9, the host motor 6 is connected with the circular saw blade 13 for driving the circular saw blade 13 to rotate, the travel motor 8 is connected with the main shaft 11, and can drive the main shaft 11 to move laterally along the crossbeam 9, and the lifting motor 7 and the main shaft 11, and can drive the main shaft to move up and down, the track 3 is arranged under the frame, the trolley 4 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com