Construction Method of Transverse Translation and Positioning of Cable-Stayed Bridge

A cable-stayed bridge, horizontal technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of long operation time, long construction period, increasing the side span of cable-stayed bridges, etc., to reduce the impact and shorten the The construction period and the effect of improving the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] specific implementation

[0032] In order to make the technical features of the present invention more clearly understood, the technical solution of the present invention will be described in detail below in conjunction with the drawings and embodiments.

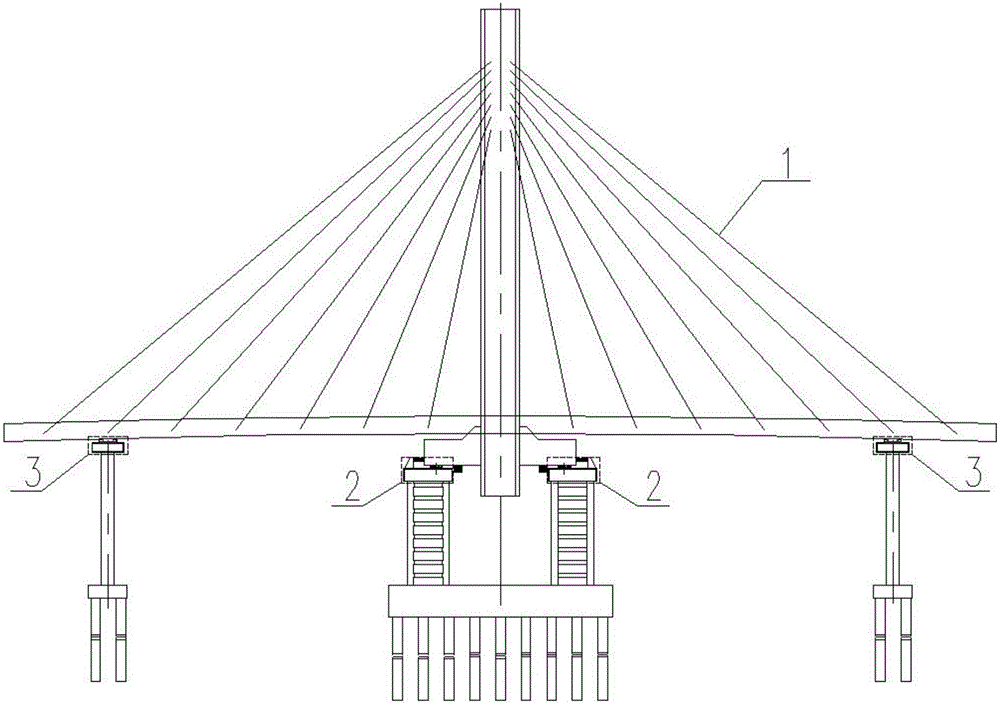

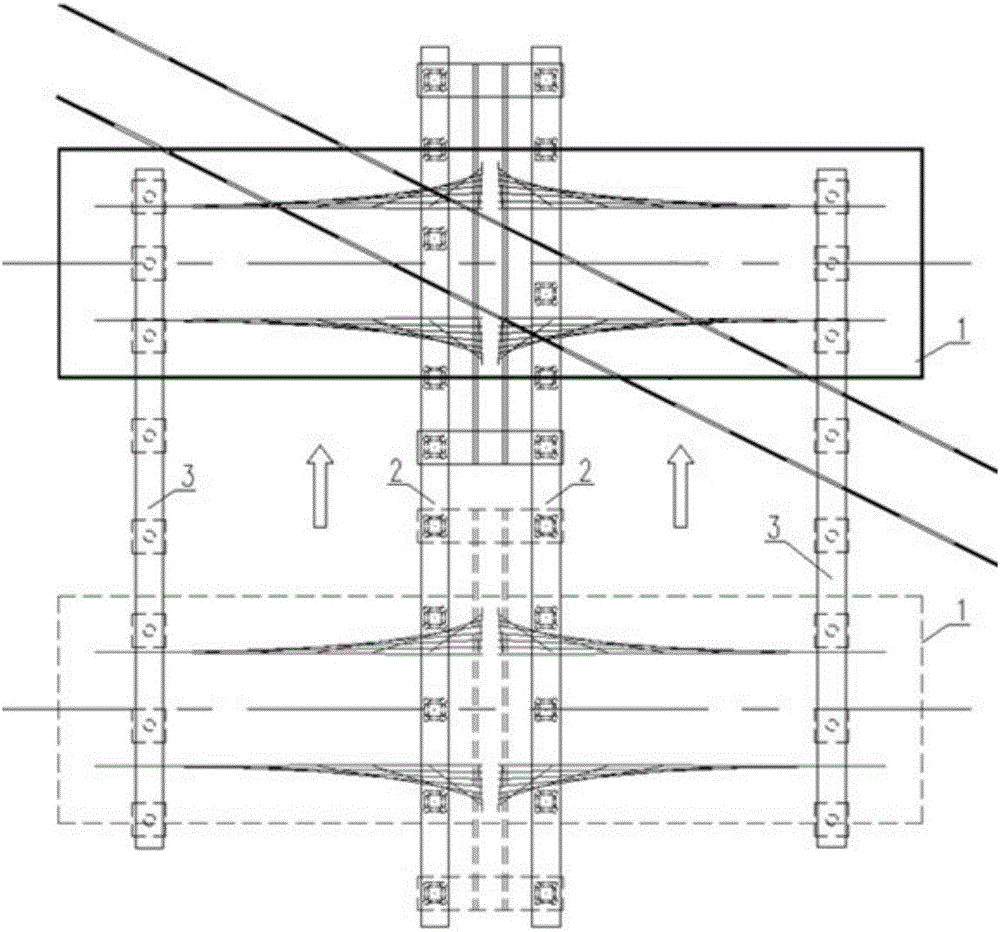

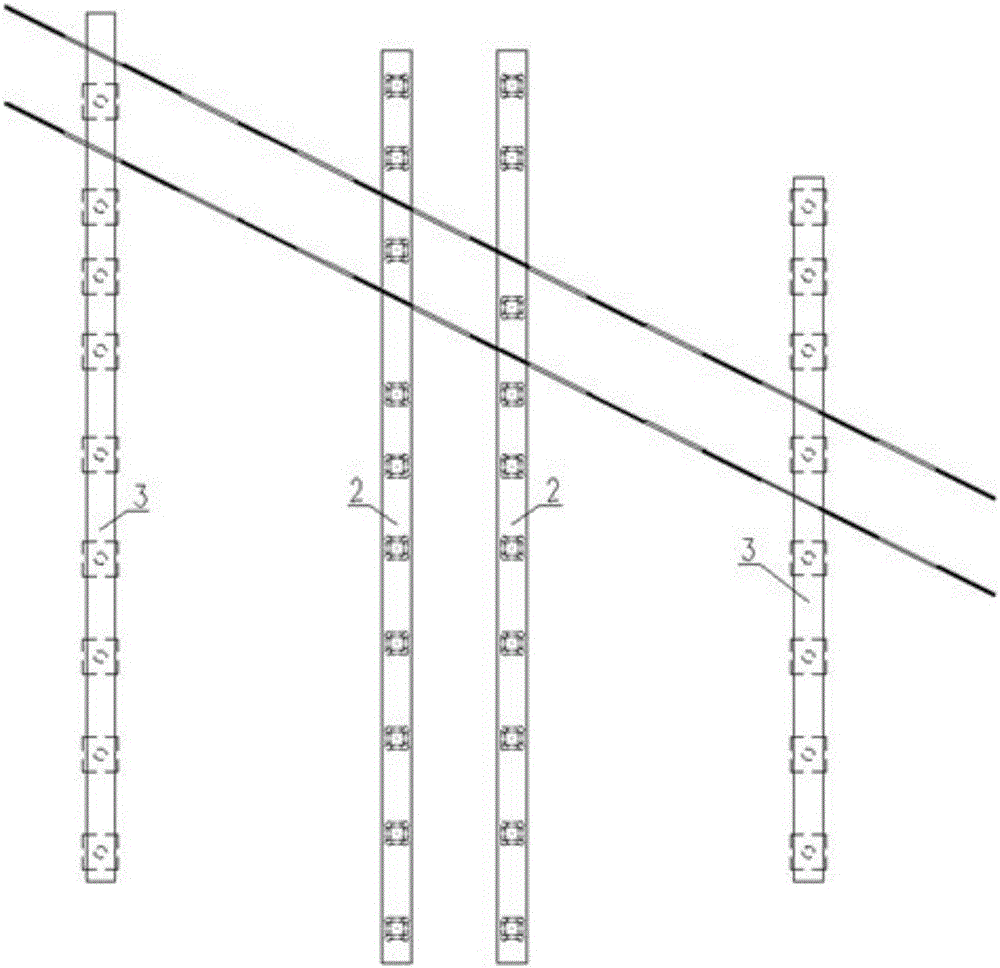

[0033] refer to figure 1 , figure 2 , image 3 The components to be used in the present invention include the continuous sliding system 2 symmetrically supported on both sides of the lateral center of the cable-stayed bridge main structure 1 and the anti-overturning system 3 respectively supported on the lateral sides of the cable-stayed bridge main structure 1 .

[0034] The construction method of the cable-stayed bridge lateral translation in place of the present invention comprises the following steps:

[0035] (1) Carry out the construction of two described continuous slip systems 2:

[0036] refer to Figure 4 and combine image 3 , the continuous sliding system 2 includes a continuous slideway beam 2a ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com