Control method and control system for obtaining high-temperature fuel in ship fuel preheating system

A medium-high temperature, fuel oil technology, applied in the direction of charging system, fuel heat treatment device, combustion air/combustion-air treatment, etc., can solve the problems of reducing pump service life, increasing system cost, grid impact, etc., and achieve service life extension , Reduce product cost, constant flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

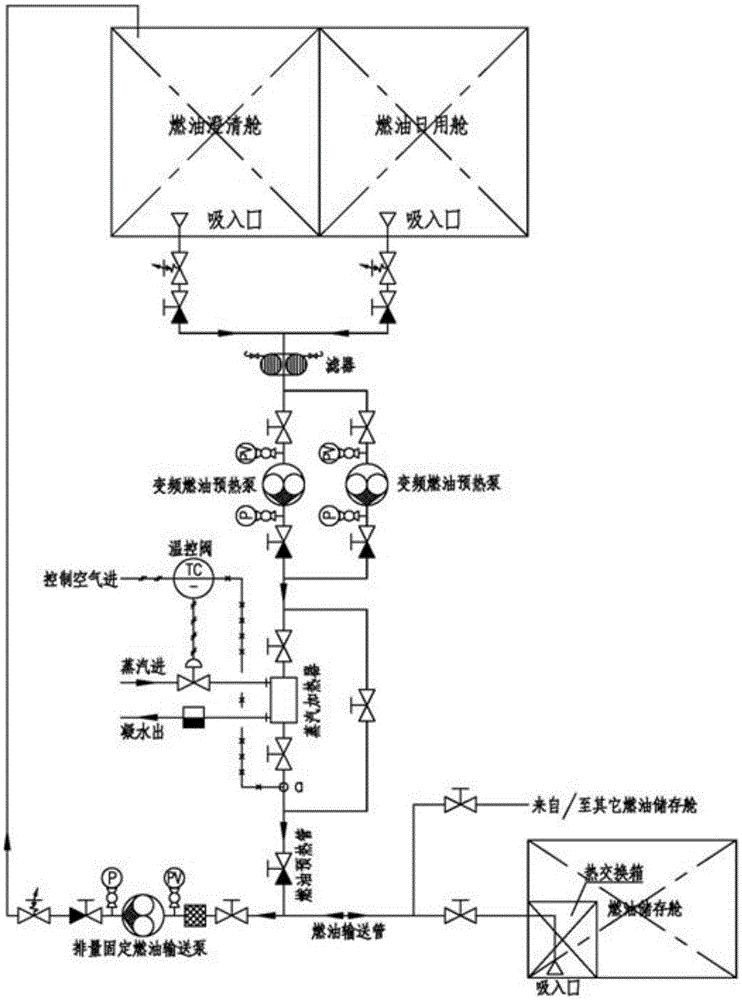

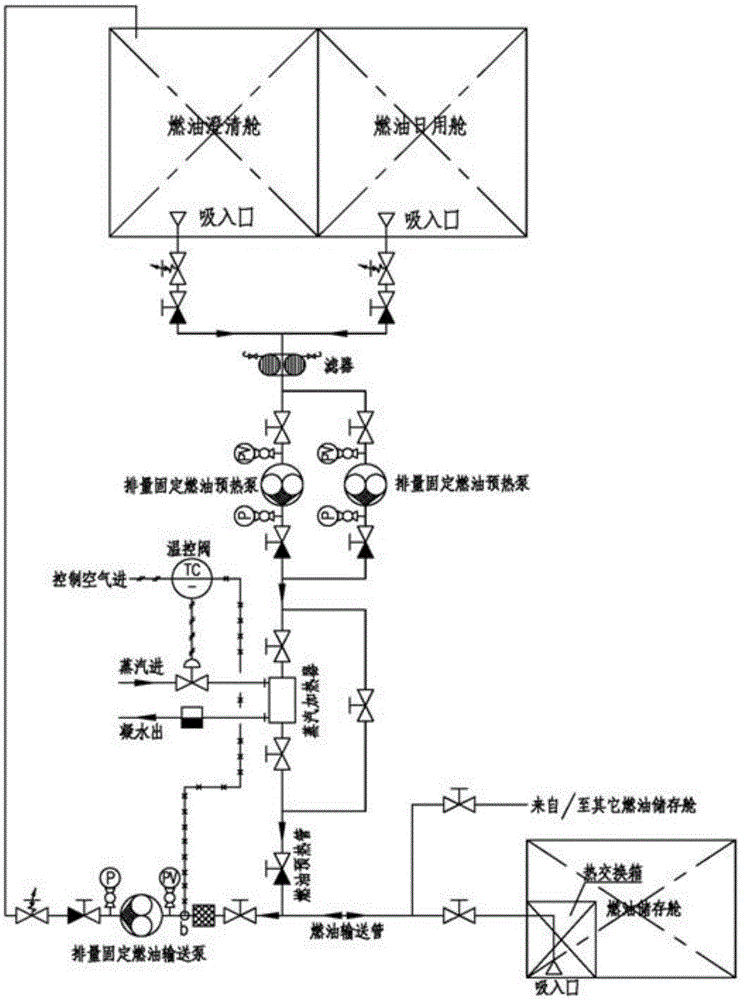

[0024] see figure 2 , a control method for obtaining high-temperature fuel oil in the fuel oil preheating system of a ship. The fixed-frequency preheat pump sucks high-temperature fuel oil from the settling tank and enters the steam heater; the high-temperature fuel heated by the steam heater enters the heat exchange box of the fuel oil storage tank, Heat the cold oil to obtain relatively high-temperature fuel; the relatively high-temperature fuel is pumped out into the settling tank through the fuel delivery pump; there is a temperature sampling point b at the inlet of the fuel delivery pump, if the temperature at point b is higher than the set value, adjust the steam valve so that Reduce the amount of steam, on the contrary, adjust the steam valve to increase the amount of steam, and finally keep the fuel temperature at the inlet of the fuel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com