Device and method for monitoring change in temperature field characteristics in gas hydration separation reaction process

A technology of hydration separation and temperature field, which is applied in the coal field, can solve the problems of low utilization rate and low gas utilization, and achieve the effects of low cost, convenient control and strong reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

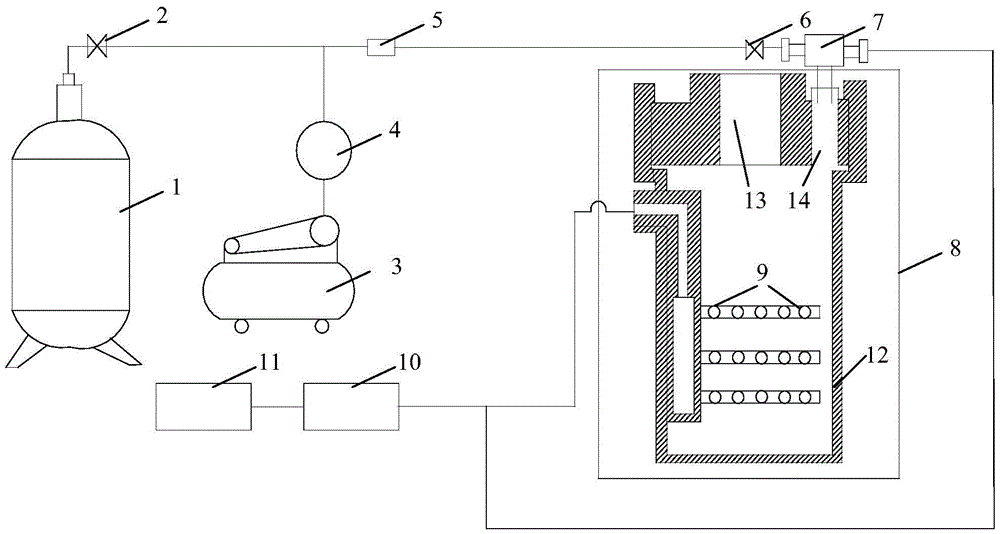

[0027] Specific implementation mode 1, refer to figure 1 Describe this embodiment in detail. A device for monitoring temperature field characteristic changes in the gas hydration separation process described in this embodiment includes a gas storage tank 1, a gas opening and closing valve 2, an air compressor 3, and a gas booster pump 4 , gas drying cylinder 5, intake stop valve 6, pressure sensor 7, high and low temperature controller 8, array temperature sensor 9, data collector 10, industrial computer 11 and visual reactor 12;

[0028] The gas storage tank 1 is used to store gas; the air compressor 3 and the gas booster pump 4 are used to press the gas in the gas storage tank 1 into the visual reactor 12;

[0029] The visible reactor 12 is used to place the solution and provide a place for the gas and the solution to react; the top of the visible reactor 12 is provided with an air inlet 14;

[0030] The gas opening stop valve 2 is arranged between the gas storage tank 1 an...

specific Embodiment approach 2

[0041] Specific embodiment 2. This specific embodiment is a further description of a device for monitoring temperature field characteristic changes in the process of gas hydration reaction described in specific embodiment 1. In this embodiment, the top of the visible reactor 12 is provided with Visual window 13.

[0042] In this embodiment, the staff observes the reaction situation in the visible reactor 12 through the visible window 13 .

specific Embodiment approach 3

[0043] Specific Embodiment 3. This specific embodiment is a further description of a device for monitoring temperature field characteristic changes in the process of gas hydration separation described in specific embodiment 2. In this embodiment, the solution is composed of a kinetic promoter and a thermodynamic promoter agent composition.

[0044] In this embodiment, the data show that the kinetic accelerator can shorten the induction period of hydrate formation and increase the rate of gas hydration separation, and the thermodynamic accelerator can improve the temperature and pressure conditions of gas hydration separation, enabling the gas hydration separation process to be carried out under milder conditions .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com