Nondestructive detection technology

A non-destructive testing and process technology, applied in the direction of measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, instruments, etc., to achieve the effects of high product quality, low experience requirements, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with embodiment:

[0041] A non-destructive testing process, including the following steps:

[0042] 1) Ultrasonic flaw detection process

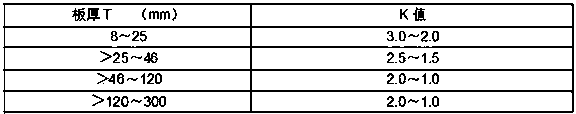

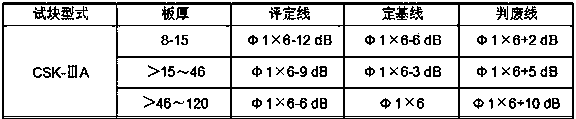

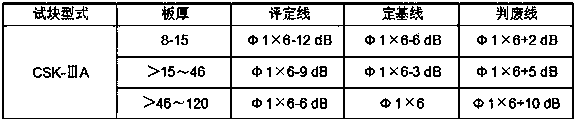

[0043] 1.1) Executive standard: JB / T4730.3-2005;

[0044] 1.2) Scanning method: the probe is perpendicular to the rolling direction of the steel plate, and the parallel lines with a spacing of 100mm are scanned; 100% scanning is performed around the groove;

[0045] 1.3) Surface requirements: The surface of the flaw detection part shall be polished to reveal metallic luster;

[0046] 1.4) Instruments and equipment:

[0047] 1.4.1) PXUT-350, PXUT-320C, CTS-22A, CTS-23 ultrasonic flaw detector;

[0048] 1.4.2) Probe: when plate thickness δ≤20mm, double crystal straight probe, chip area not less than 150mm2, probe nominal frequency 5.0MHz; when δ>20mm, single crystal straight probe, circular chip diameter φ14~25mm, probe nominal frequency 2.5MHz;

[0049] 1.4.3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com