Ferrograph abrasive particle composite characteristic construction method based on heredity programming

A technology of genetic programming and compound features, which is applied in the field of mechanical equipment fault diagnosis, can solve problems such as time-consuming, labor-intensive blindness, etc., and achieve the effect of improving capabilities and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

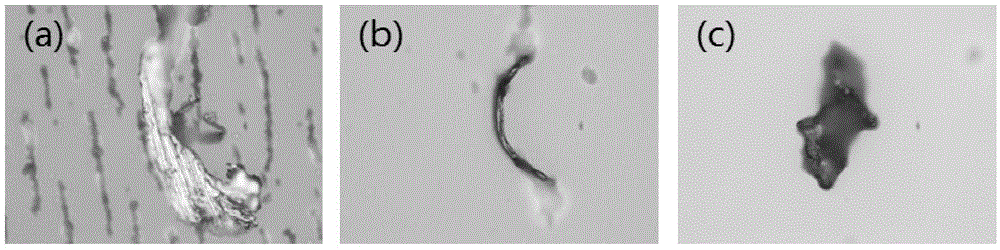

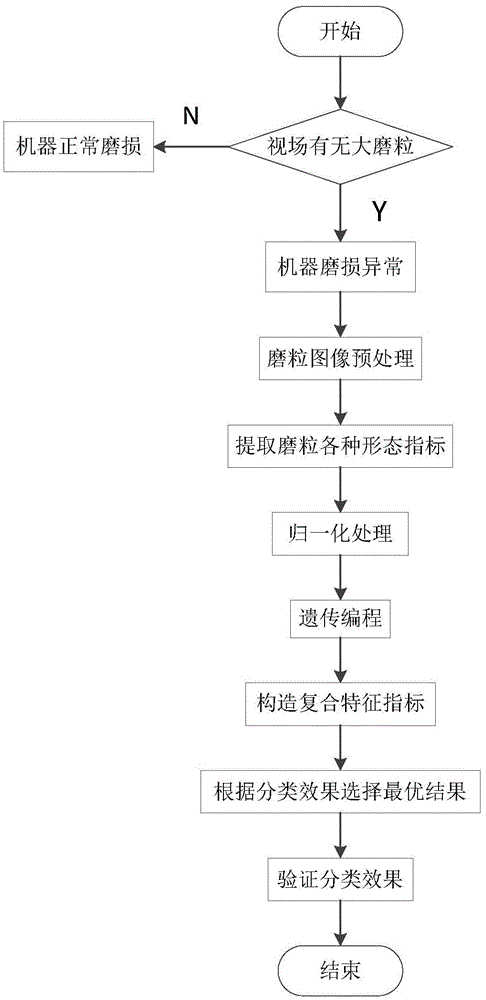

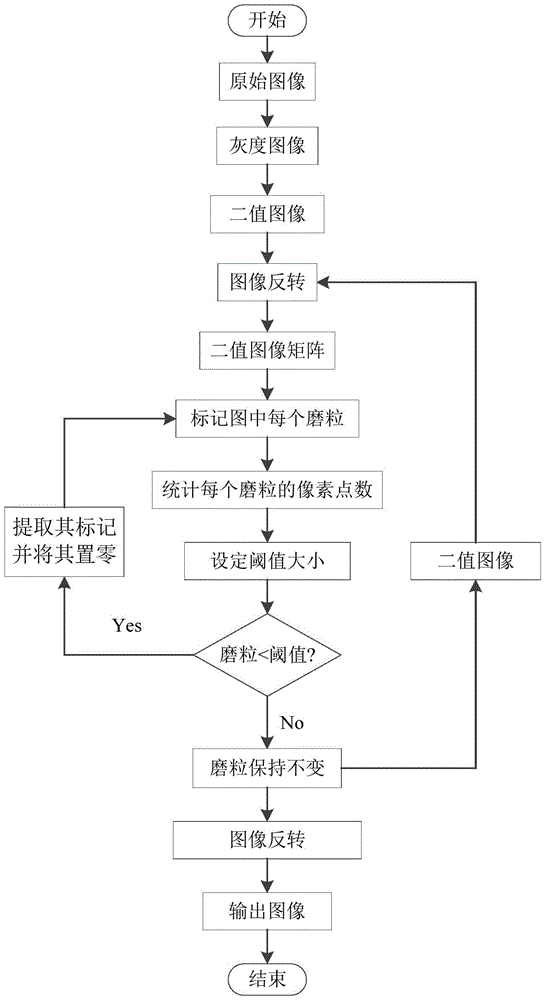

[0041] In the present invention, firstly, five morphological features are obtained by processing the obtained ferrographic wear particle image. Considering that the value range of each feature is quite different, before genetic programming, each morphological feature is normalized to ensure that the value range of each morphological feature is [0,1]. The normalized ferrographic wear particle characteristics are used as the initial sample population of genetic programming, and the five initial characteristics are recombined and optimized by genetic programming, and the expression is output by post-order traversal, and finally the fitness function is used to select the most Excellent compound features. Using the obtained composite feature as a new index, different types of faulty abrasive particles can be distinguished intuitively.

[0042] seefigure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com