An automatic wiring system for an intelligent control cabinet

A technology of intelligent control cabinet and automatic wiring, applied in connection, circuit/collector parts, connection and connection completed by deformation, etc., can solve problems such as low debugging efficiency, and achieve the effect of solving low debugging efficiency and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

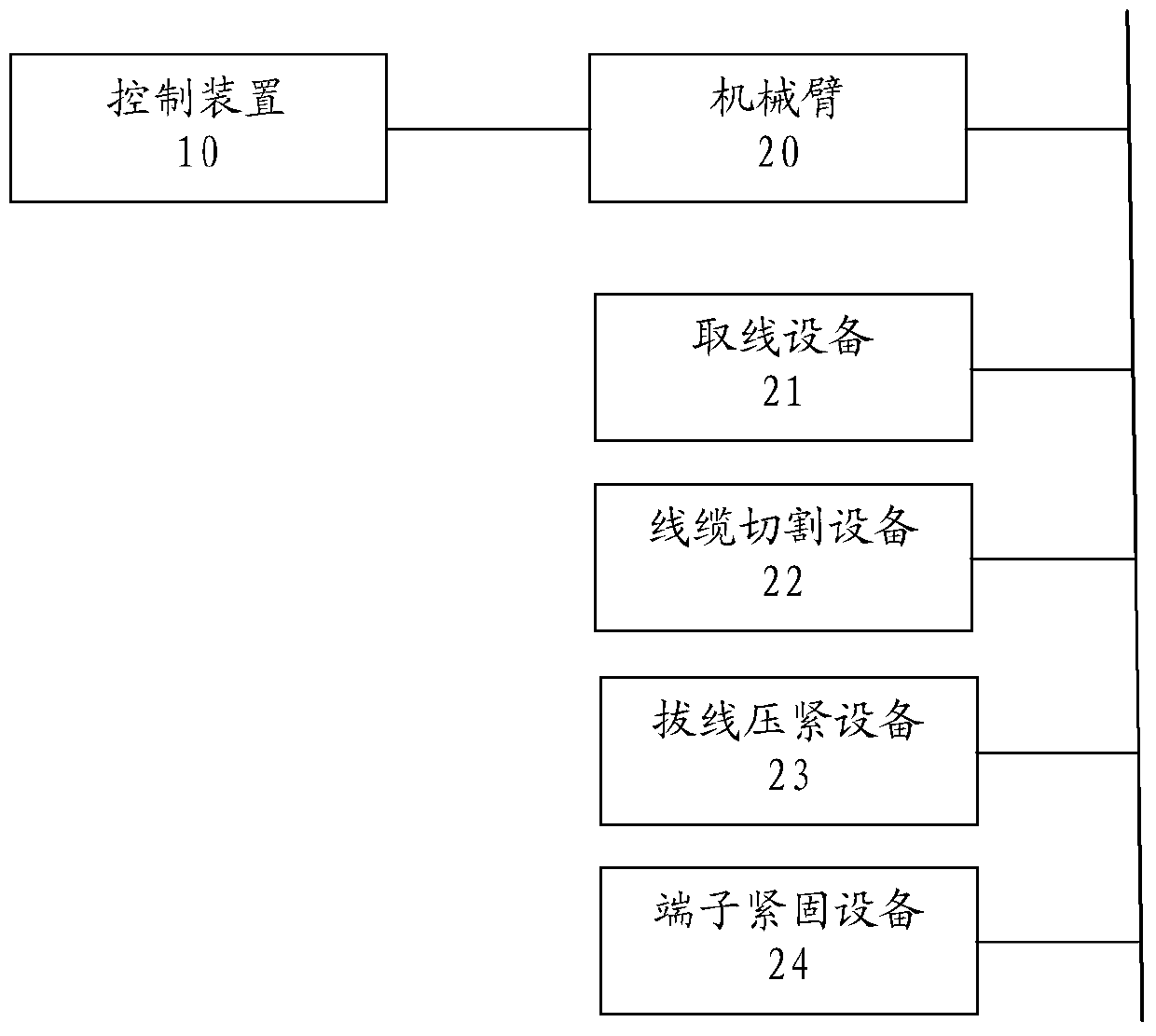

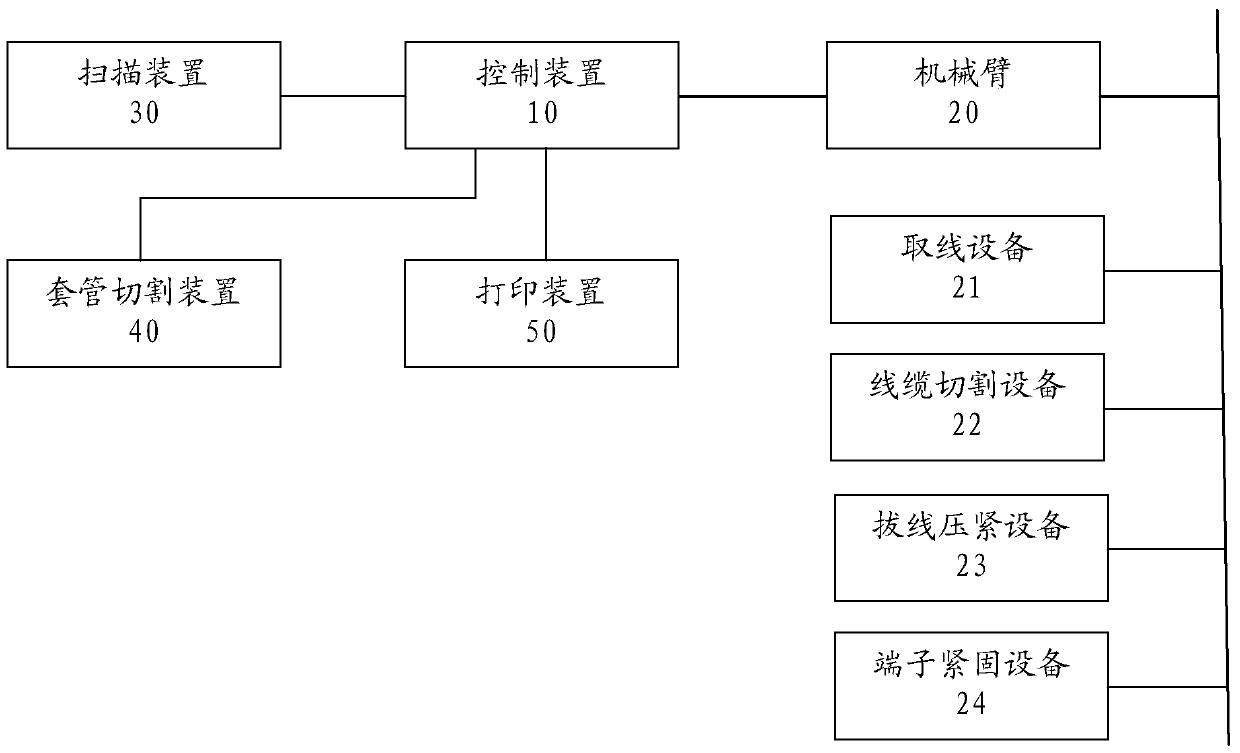

[0031] figure 1 It is a schematic diagram of an automatic wiring system for an intelligent control cabinet provided in an embodiment of the present application.

[0032] Such as figure 1 As shown, the automatic wiring system of the intelligent control cabinet provided by the present application includes a control device 10 and a robot arm 20 , and the control device 10 is connected to the robot arm 20 for controlling the robot arm 20 .

[0033] A plurality of devices are disposed on the mechanical arm 20 , including a wire taking device 21 , a cable cutting device 22 , a wire pulling and pressing device 23 and a terminal fastening device 24 .

[0034] The control device 10 stores connection parameters of the intelligent control cabinet, and the connection parameters include terminal positions and terminal numbers of the connection terminals of the intelligent control cabinet. When performing wiring operations on the intelligent control cabinet, the control device outputs mot...

Embodiment 2

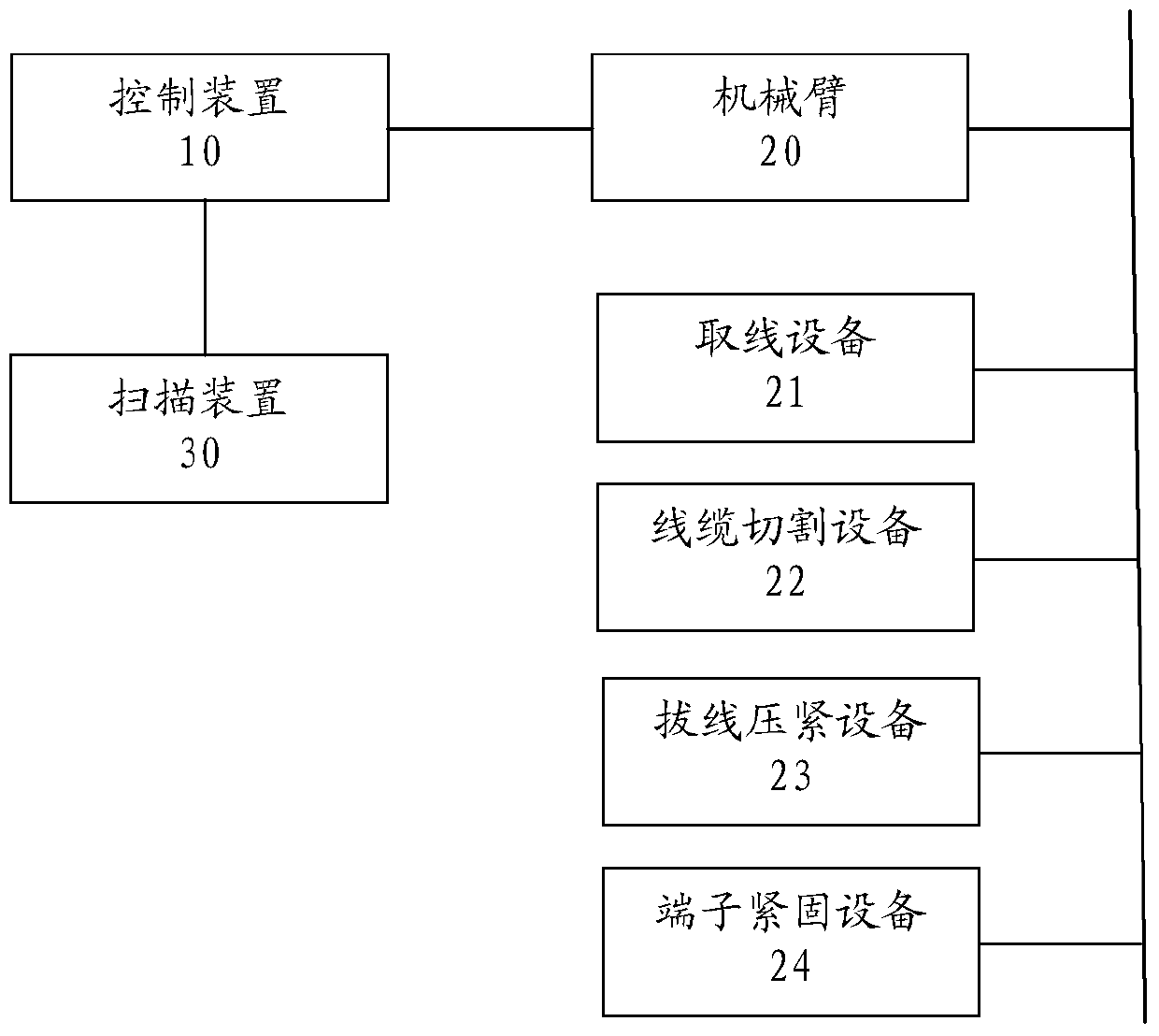

[0044] figure 2 It is a schematic diagram of an automatic wiring system for an intelligent control cabinet provided in another embodiment of the present application.

[0045] Such as figure 2 As shown, the automatic wiring system provided in this embodiment is based on the previous embodiment with an additional input device 60, which is connected to the control device.

[0046] Operators can use the input device 60 to input drawings containing wiring parameters into the control device, so that the system can meet the wiring tasks of different types of intelligent control cabinets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com