Hot-melt adhesive

A hot-melt adhesive and adhesive technology, applied in the direction of adhesives, adhesive types, polymer adhesive additives, etc., can solve the problems of poor fluidity, heavy labor, long-term storage, difficult transportation, etc. Achieve the effects of excellent adhesion, excellent blocking resistance, and excellent storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

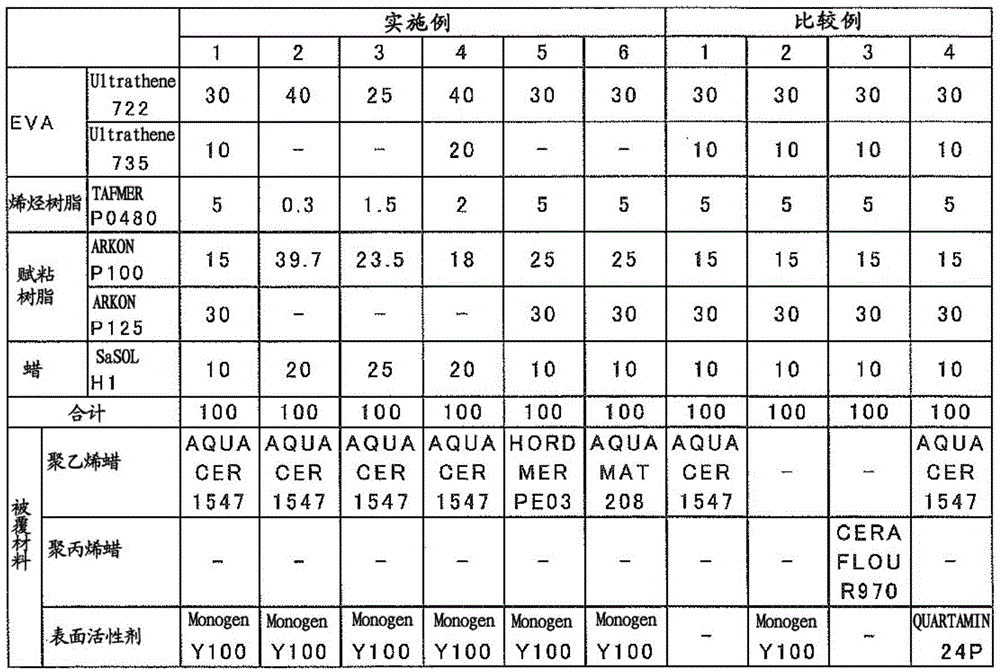

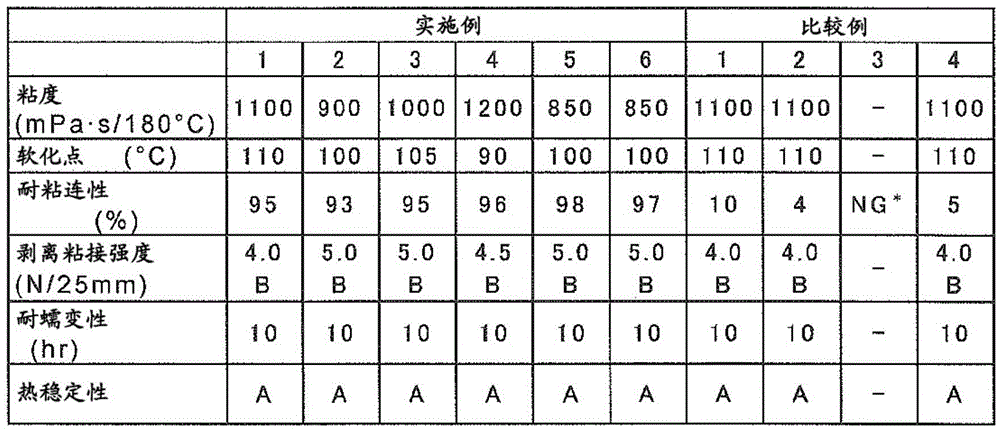

Embodiment 1~6、 comparative example 1~4

[0069] According to the composition shown in Table 1, a hot-melt adhesive was prepared. The compounding unit in the table is mass %.

[0070] The ethylene-vinyl acetate copolymer (EVA) used in the study was Ultrathene 722 (trade name manufactured by Tosoh Corporation, vinyl acetate (VA) content of 28% by mass, melt flow rate (MFR) = 400, Universal Softening point 82° C.) and Ultrathene 735 (trade name manufactured by Tosoh Corporation, VA content 28% by mass, melt flow rate (MFR) = 1000, softening point 85° C. ring and ball method).

[0071] As the olefin resin, TAFMERP0480 (trade name, ethylene-propylene-based α-olefin copolymer resin manufactured by Mitsui Chemicals, Inc.) was used.

[0072] As the tackifying resin, ARKONP100 (trade name manufactured by Arakawa Chemical Industry Co., Ltd., hydrogenated C9 petroleum resin, softening point 100° C.) and ARKONP125 (trade name manufactured by Arakawa Chemical Industry Co., Ltd., hydrogenated C9 petroleum resin) were used. , sof...

Embodiment 7~10、 comparative example 5~8

[0105] According to the compounding shown in Table 3, it carried out similarly to Example 1 etc., and produced the spherical hot-melt-adhesive. The compounding unit in Table 3 is mass %.

[0106] As the olefin resin, RT2585A (trade name manufactured by REXTAC, LLC, ethylene-propylene-based α-olefin copolymer resin) was used. As other components, the same materials as in Example 1 and the like were used.

[0107] table 3

[0108]

[0109] About the obtained hot-melt adhesive, the softening point, blocking resistance, and Shore hardness were evaluated. Shore hardness was evaluated by the method shown below. Other evaluations were performed by the same methods as in Example 1 and the like. The results are shown in Table 4.

[0110] Shore hardness

[0111] The Shore hardness at 23° C. of each hot-melt adhesive was measured in accordance with JISA Shore hardness.

[0112] Table 4

[0113]

[0114] **Because polypropylene wax does not mix with surfactants, cover materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com