Production method of rose-aroma concentrated grape juice

A technology of grape juice concentrate and production method, which is applied in food processing, food science, food freezing and other directions, can solve the problems of unsalable grapes, strong seasonality of grapes, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

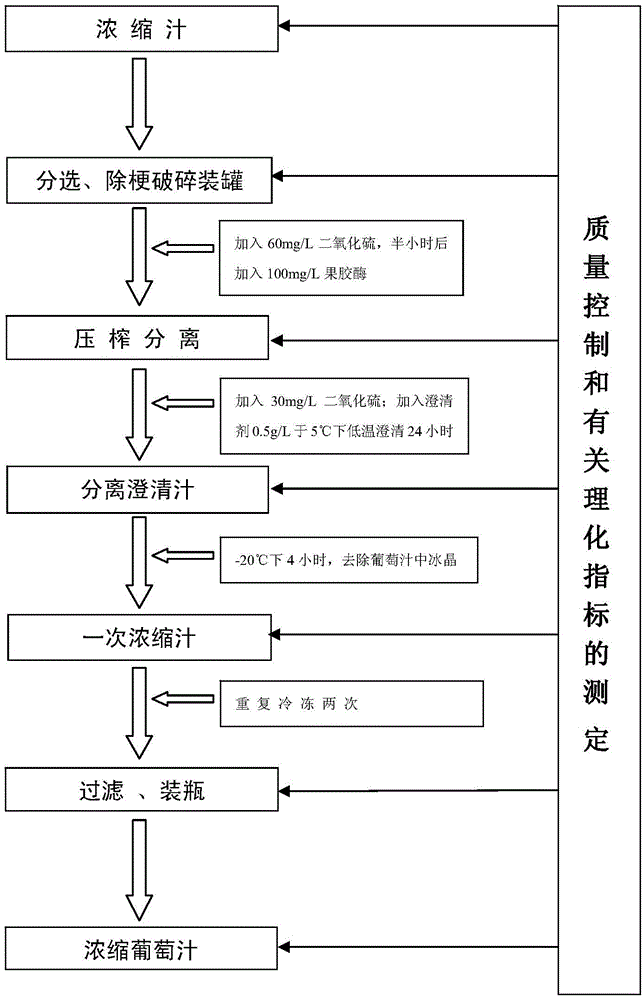

[0015] The specific implementation steps of the present invention are as follows:

[0016] The step ① sorting grape raw materials, removing mildewed and damaged grape berries, using a destemming crusher to destem and crush, adding 60 mg / L of sulfur dioxide (to prevent oxidative browning), and adding 100 mg / L of pectin after half an hour Enzyme reaction for 4 hours (increasing grape juice yield);

[0017] 1. Step 2. Squeeze and separate the grape juice, clarification of the grape juice: Utilize the press to extract the juice from the crushed grapes, add 60mg / L sulfur dioxide (to prevent oxidative browning) into the separated juice, and then add 0.6g / Llaffort Bentonite is placed at 5°C for 24 hours to clarify the grape juice. In this step, in order to make the obtained grape juice more clear, precipitation is not easy to occur in subsequent steps;

[0018] Step 3. Freeze concentration of grape juice: place the separated clarified grape juice at -20°C for 4 hours, remove the ice...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com