A method for efficiently separating black tungsten concentrate and scheelite concentrate from tungsten ore

A technology of black and white tungsten and concentrate, applied in the field of comprehensive utilization of tungsten ore resources, can solve the problems of low flotation recovery rate of wolframite, low separation efficiency of black and white tungsten, inconsistent pH range, etc., and achieve high quality scheelite concentrate, Efficient flotation separation and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

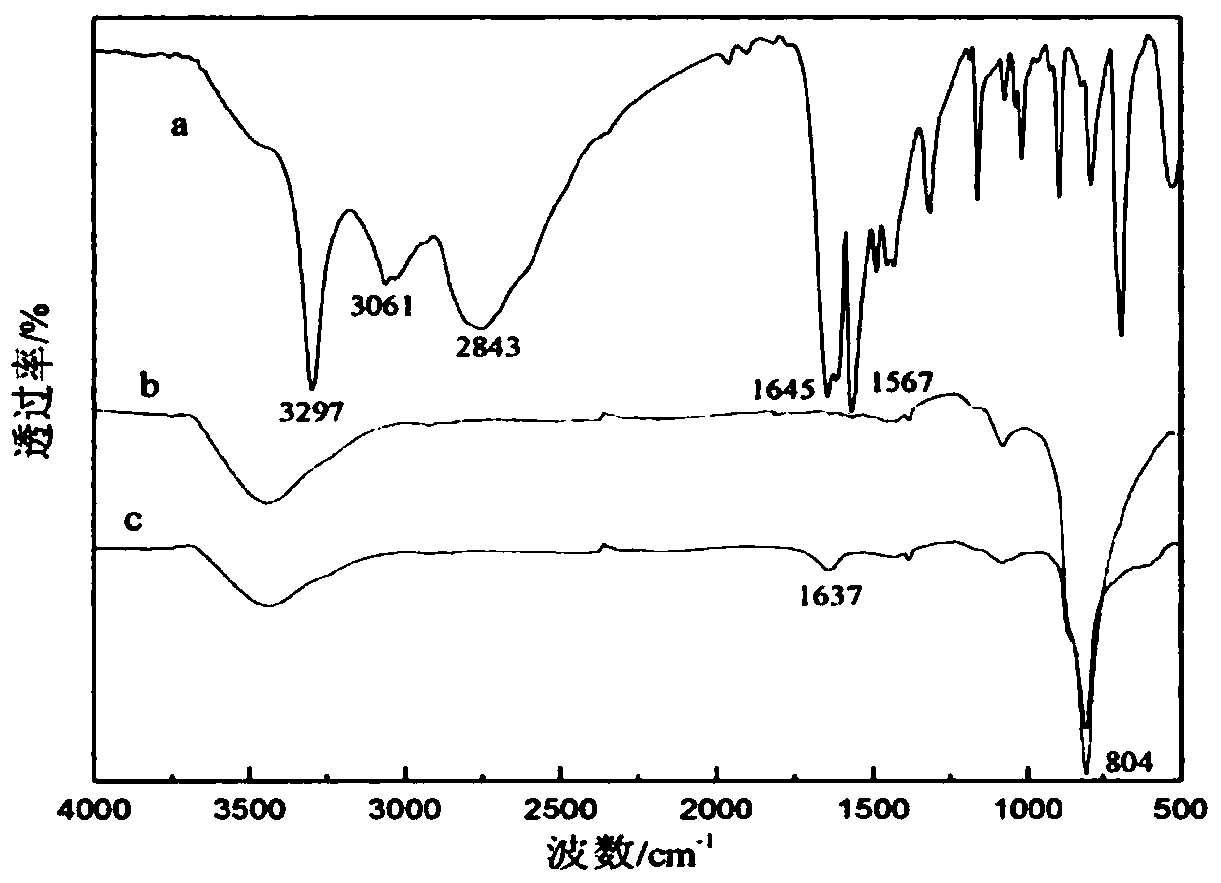

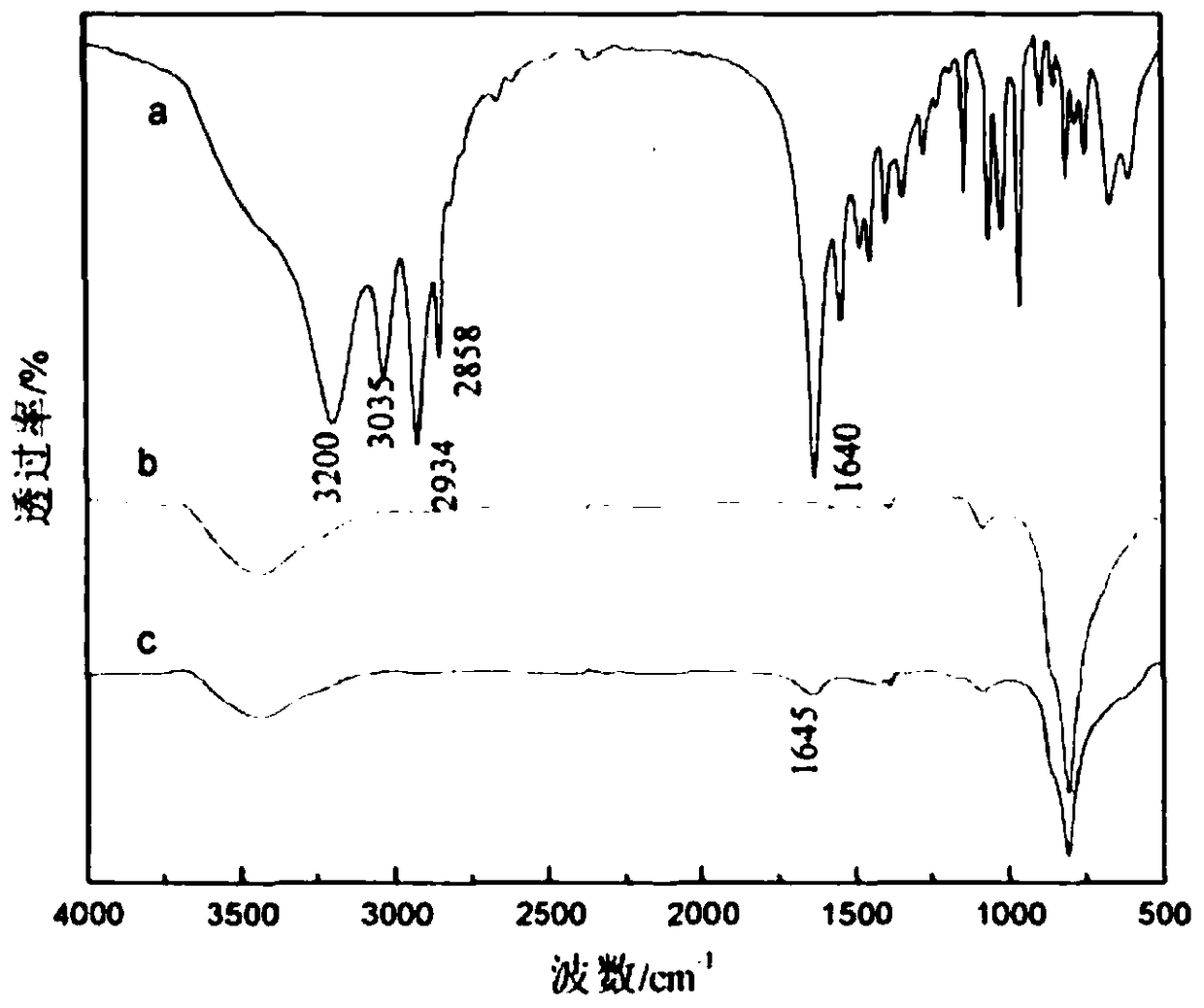

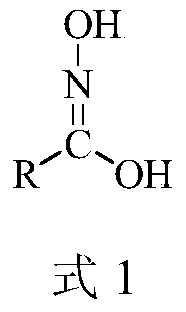

[0063] Mix 1mol / L benzoic acid with 3mol / L anhydrous methanol, slowly add 30mL of concentrated acid, add a few grains of zeolite, heat to 75°C and reflux for 2h. Distill off excess methanol with a distillation device, and the residue is washed three times to obtain the corresponding ester; add 2.2 mol of hydroxylamine hydrochloride into a single-necked flask, and add 50 mL of ethanol, stir and cool in a water bath, add 88 g of sodium hydroxide therein, Stir in a water bath for 2 hours, filter out insoluble free hydroxylamine to obtain free hydroxylamine hydrochloride; add free hydroxylamine hydrochloride and 25mL methanol to a three-necked flask equipped with an electric stirrer and a dropping funnel, and stir dropwise at 45°C Add 1.7 mol of the obtained ester, react for 45 minutes after the dropwise addition, add 0.5 mol of lead nitrate to the solution obtained in the third step under stirring conditions, and keep the reaction at 40°C for 2 hours to obtain the complex collecto...

Embodiment 2

[0068] Mix 1mol / L salicylic acid with 3mol / L anhydrous methanol, slowly add 30mL of concentrated acid, add a few grains of zeolite, heat to 80°C and reflux for 1h. Distill off excess methanol with a distillation device, and the residual liquid is washed 5 times to obtain the corresponding ester; add 2.2 mol of hydroxylamine hydrochloride into a single-necked flask, and add 50 mL of ethanol, stir and cool in a water bath, add 88 g of sodium hydroxide to it, Stir in a water bath for 1.5h, filter out insoluble free hydroxylamine to obtain free hydroxylamine hydrochloride; add free hydroxylamine hydrochloride and 25mL methanol to a three-neck flask equipped with an electric stirrer and a dropping funnel, and stir at 48°C Add 1.7 mol of the obtained ester dropwise, react for 45 minutes after the dropwise addition, add 0.25 mol of aluminum sulfate to the solution obtained in the third step under stirring conditions, and keep the reaction at 40° C. for 2 hours to obtain the complex co...

Embodiment 3

[0073] Utilize this process to process Yaogangxian tungsten-tin-molybdenum-bismuth polymetallic ore, adjust the pH of the desulfurization tailings to 7.8 by sodium carbonate, add metal ion ligand collector (prepared in Example 1) 500g / t, inflate the slurry and stir 5min, after a rough and a fine double sweep flotation operation to obtain WO 3 53% black and white tungsten mixed concentrate, after the mixed concentrate passes through the thickener, put it into the mixing tank, the mass concentration of the pulp is 72%, add sodium oleate, sodium sulfide, caustic soda, water glass 2Kg / t, 8Kg / t, 1Kg / t, 80Kg / t, stirring speed 800r / min, high-speed stirring 1, flotation separation after slurry mixing is completed, foam product is added with 8Kg / t nitric acid with a mass fraction of 10% for dephosphorization treatment to obtain WO 3 73% scheelite concentrate, adding 3Kg / t of sulfuric acid to the flotation tailings, settling, filtering and drying, it is WO 3 36% wolframite concentrate....

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com